Food adsorption and antibacterial pad and preparation method thereof

A technology of food and antibacterial layer, applied in the field of adsorption antibacterial mat and its preparation for cold fresh meat on trays, to achieve the effect of extending shelf life, reducing bacteria and odor, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: Food adsorption antibacterial pad and preparation method thereof

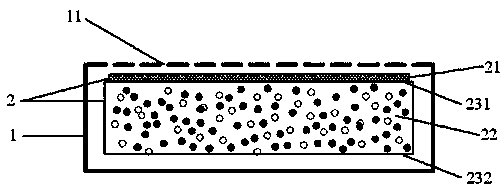

[0033] Please see figure 1 , figure 1 It is a structural schematic diagram of a food adsorption antibacterial pad of the present invention. First dissolve 2g of nisin, 2g of cinnamon essential oil, 1g of chitosan, 1g of lysozyme, and 1g of green tea extract in 20% ethanol solution, then add 180g of EVA emulsion adhesive, and then stir for 60 minutes at room temperature to obtain a well-mixed Antimicrobial coating solution.

[0034] Cut the first non-woven fabric 231 of 140mm*80mm, and then use an automatic film coating machine to evenly coat 40g of antibacterial coating solution on the upper surface of the first non-woven fabric 231, and finally dry it in a constant temperature drying oven at 60°C After 5 hours, the first nonwoven fabric 231 containing the antibacterial coating 21 was obtained.

[0035] Cut the second non-woven fabric 232 of 140mm*80mm, evenly coat a layer of adhesive...

Embodiment 2

[0037] Embodiment 2: food adsorption antibacterial pad and preparation method thereof

[0038] Please see figure 1 , figure 1 It is a structural schematic diagram of a food adsorption antibacterial pad of the present invention. First dissolve 5g of nisin, 4g of cinnamon essential oil, 2g of chitosan, 3g of lysozyme, and 1g of green tea extract in 20% ethanol solution, then add 160g of EVA emulsion adhesive, and then stir for 50 minutes at room temperature to obtain a well-mixed Antimicrobial coating solution.

[0039] Cut the first non-woven fabric 231 of 140mm*80mm, and then use an automatic film coating machine to evenly coat 30g of antibacterial coating solution on the upper surface of the first non-woven fabric 231, and finally dry it in a constant temperature drying oven at 60°C After 4 hours, the first nonwoven fabric 231 containing the antibacterial coating 21 was obtained.

[0040] Cut the second non-woven fabric 232 of 140mm*80mm, evenly coat a layer of adhesive...

Embodiment 3

[0042] Embodiment 3: Food adsorption antibacterial pad and preparation method thereof

[0043] Please see figure 1 , figure 1 It is a structural schematic diagram of a food adsorption antibacterial pad of the present invention. First dissolve 10g of nisin, 10g of cinnamon essential oil, 3g of chitosan, 5g of lysozyme, and 2g of green tea extract in 20% ethanol solution, then add 130g of EVA emulsion adhesive, and then stir at room temperature for 50 minutes to obtain a well-mixed Antimicrobial coating solution.

[0044] Cut the first non-woven fabric 231 of 180mm*120mm, and then use an automatic film coating machine to evenly coat 25g of antibacterial coating solution on the upper surface of the first non-woven fabric 231, and finally dry it in a constant temperature drying oven at 60°C After 3 hours, the first non-woven fabric 231 containing the antibacterial coating 21 was obtained.

[0045]Cut the second non-woven fabric 232 of 180mm*120mm, evenly coat a layer of adhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com