Inorganic mineral environment-friendly fire-retardant coating and preparation method thereof

A technology of fire-resistant coatings and inorganic minerals, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of toxicity, etc., achieve the effects of avoiding peeling, easy construction, and improving the water resistance of the coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

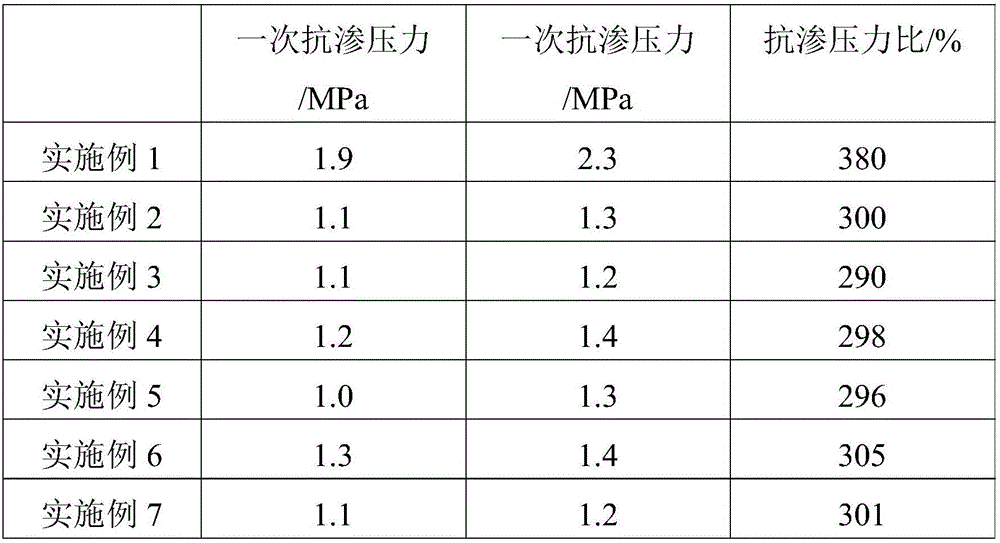

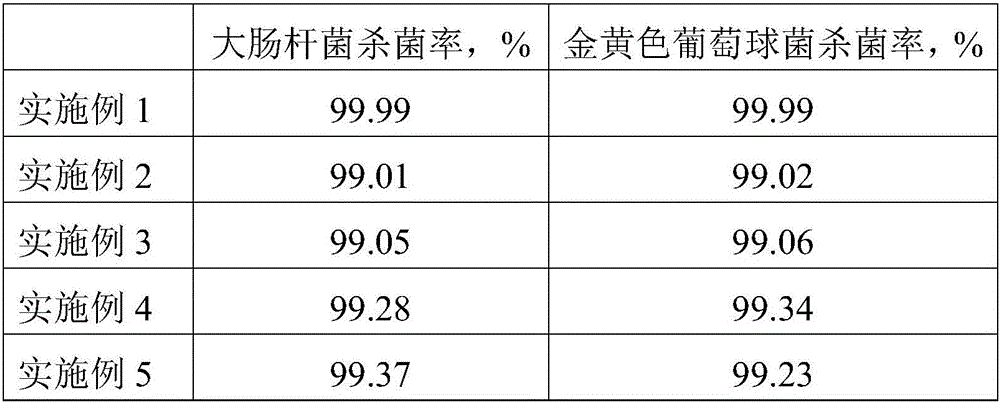

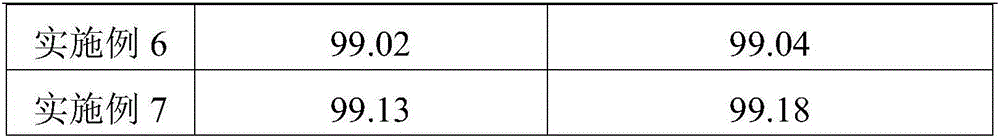

Examples

Embodiment 1

[0041] Weigh each raw material (parts by weight): potassium silicate solution 3000g, dispersant 150g, thickener 150g, simethicone 300g, acrylic emulsion 600g, titanium dioxide 1000g, iron oxide 600g, sepiolite 600 parts, zinc oxide 500g , Tourmaline 600g, kaolin 300g, silica sol 200g, water 2000g.

[0042] Described thickener is mixed by 50g hydroxypropyl starch, 50g carboxymethyl starch, 50g hydroxypropyl methylcellulose.

[0043] The dispersant is formed by mixing 50g sodium hexametaphosphate, 50g sodium pyrophosphate and 50g sodium tripolyphosphate.

[0044] The preparation of inorganic mineral environmental protection fireproof coating comprises the following steps:

[0045] (1) Potassium silicate solution 3000g, dispersant 150g, thickener 150g, simethicone 300g, acrylic emulsion 600g, titanium dioxide 1000g, iron oxide 600g, sepiolite 600 parts, zinc oxide 500g, tourmaline 600g, Add 300g of kaolin, 200g of silica sol, and 2000g of water into the dispersion kettle, and s...

Embodiment 2

[0049] The inorganic mineral environment-friendly fireproof coating was prepared according to the raw material ratio and method of Example 1, the only difference being that the thickener was mixed with 75g of hydroxypropyl starch and 75g of carboxymethyl starch. Obtain the inorganic mineral environmental protection fireproof coating of embodiment 2.

Embodiment 3

[0051] Prepare the inorganic mineral environment-friendly fireproof coating according to the raw material ratio and method of Example 1, the only difference is that the thickener consists of 75g hydroxypropyl starch and 75g hydroxypropyl methylcellulose. Obtain the inorganic mineral environmental protection fireproof coating of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com