Raw bamboo fiber and polypropylene staple fiber composite molding interior panel and preparation process thereof

A technology of polypropylene staple fiber and bamboo fiber, which is applied in the direction of superstructure sub-assembly, lamination and layered products, etc., can solve the problems of physical health impact and low strength of people in the car, and achieve excellent dimensional stability and bending. High strength and easy forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

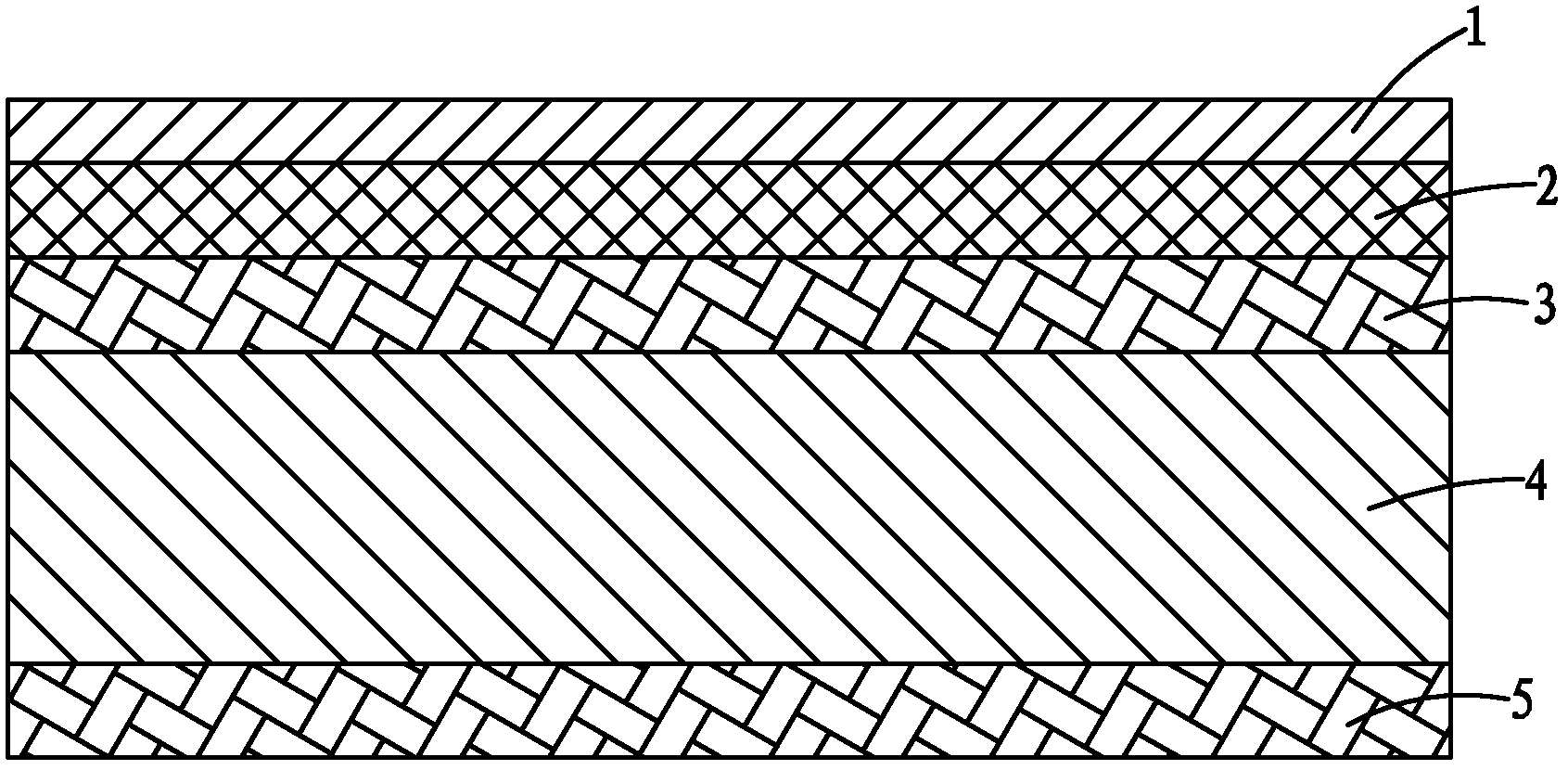

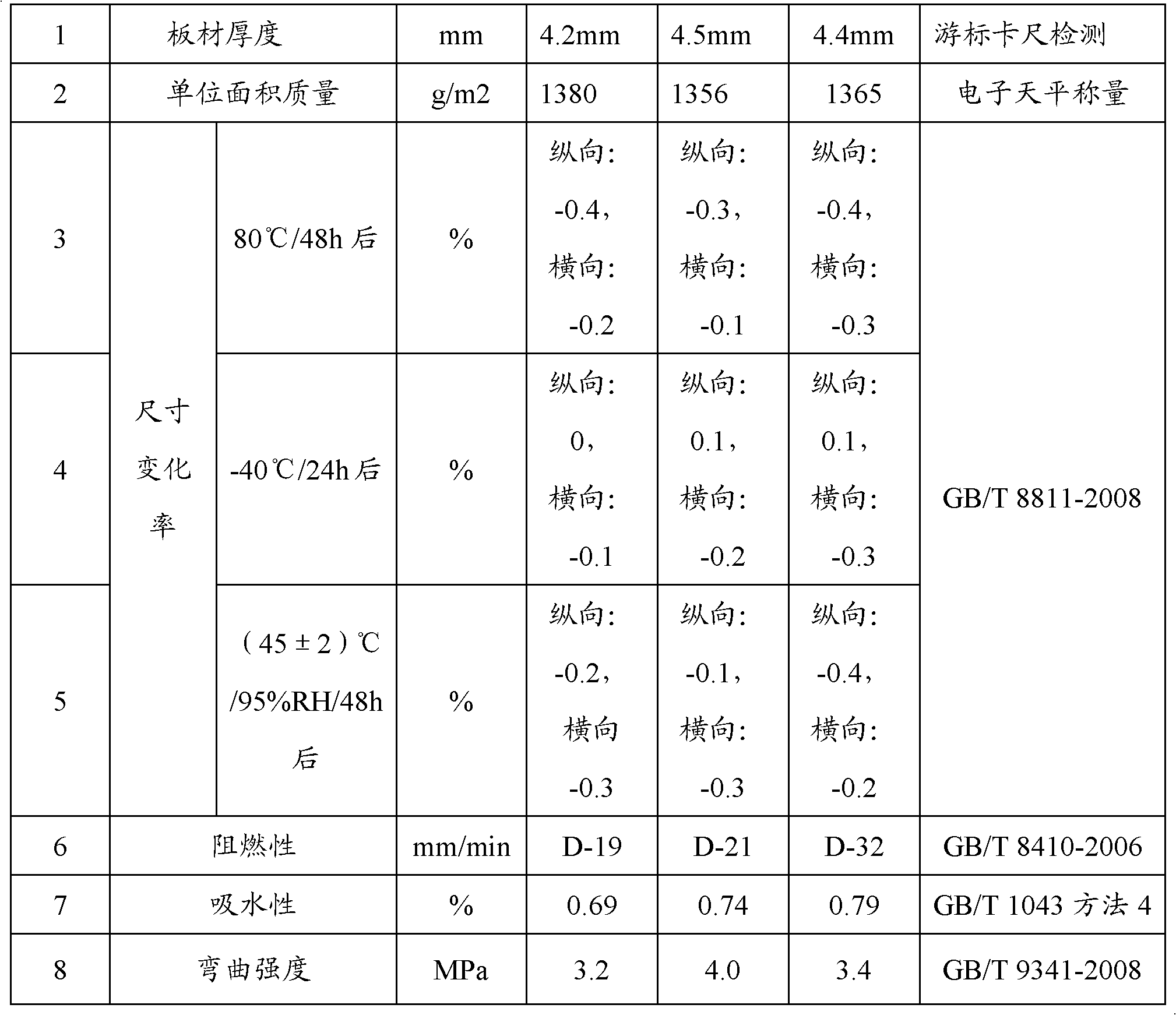

[0018] Such as figure 1 Shown, a kind of bamboo raw fiber and polypropylene staple fiber are compositely molded trim board, and the surface layer of described trim board is a decorative fabric 1, and the second layer is a hot-melt adhesive film 2, and the 3rd layer is a first non-woven fabric. Woven fabric 3, the fourth layer is a bamboo fiber and polypropylene short fiber mixed needle felt 4, the fifth layer is a second non-woven fabric 5; the combination of bamboo fiber and polypropylene short fiber mixed needle felt 4 The percentage by weight is: 53% to 56% of bamboo fiber, 44% to 47% of polypropylene staple fiber; the square gram weight of the bamboo fiber and polypropylene staple fiber mixed needle felt 4 is 1200g / m 2 ~1400g / m 2 ; The bamboo fiber: the linear density is 32dtex ~ 65dtex, the fiber length is 51mm ~ 80mm, the breaking strength is ≥ 21.2cN / dtex, and the antibacterial performance is ≥ 70%; the polypropylene short fiber: the linear density is 6.8dtex ~ 7.8dtex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com