PVC composite material suitable for extrusion molding and preparation method

A technology for extrusion molding and PVC resin powder, which is applied in the field of PVC composite materials and preparation, can solve the problems of poor toughness, poor fluidity, and easy decomposition of molded products, and achieve the effects of not easy to decompose, good compatibility, and good toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The PVC composite material suitable for extrusion molding of the present invention and preparation method comprise the following steps:

[0026] 1) Preparation of modified waste mineral powder

[0027] 1a) After extracting the magnet powder from the tailings generated by mining granite through the magnet powder production line, the waste mineral powder a is obtained through drying, crushing, grinding and sieving; Mineral powder b; waste ore powder c is obtained by grinding and sieving the coal-burning fly ash produced in the smelting process; the grinding fineness is 300-400 mesh;

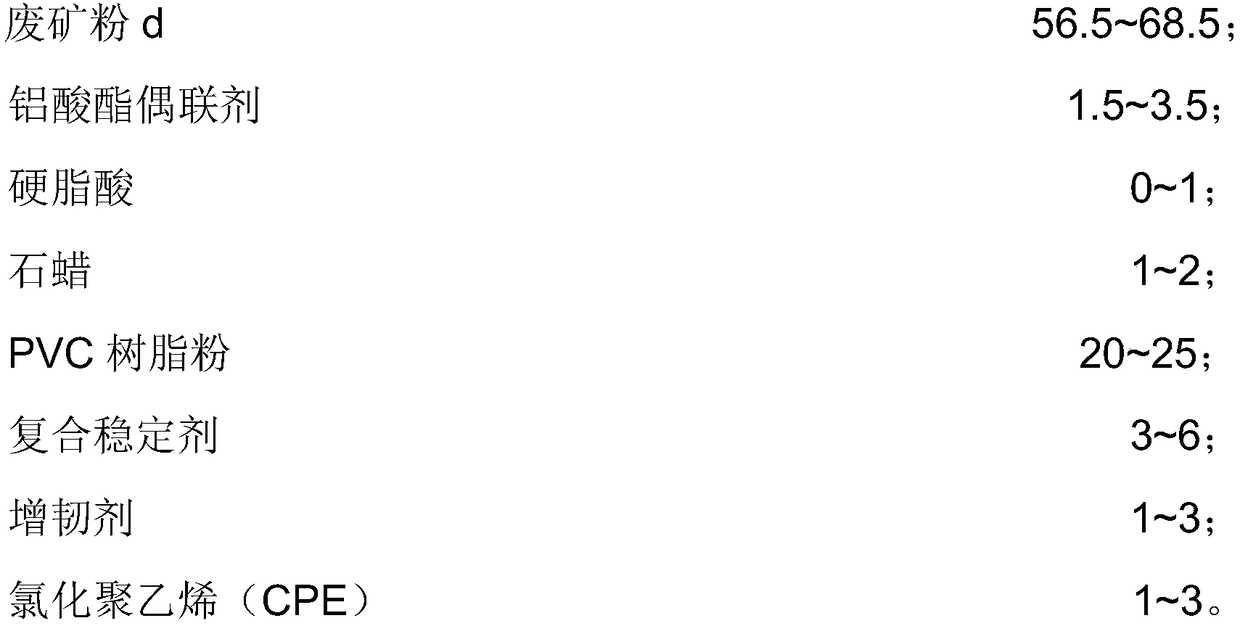

[0028] 1b) Mix waste mineral powder a, waste mineral powder b, and waste mineral powder c at a low speed in any proportion to obtain waste mineral powder d, and then mix waste mineral powder d with 56.5-68.5% of waste mineral powder and 1.5-3.5% aluminate Ester coupling agent (distearyloxy isopropyl aluminate) at 70-90°C, 500-1000 rpm, stirring and mixing for 30-60min, cooling to 30-40°C to...

Embodiment 1

[0036] Prepare PVC composite materials according to the following raw materials:

[0037]

[0038]

[0039] Specific implementation steps:

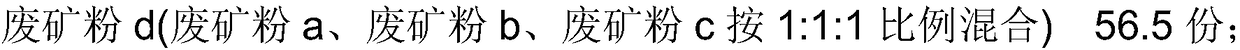

[0040] 1) Grind waste mineral powder a, waste mineral powder b and waste mineral powder c to a fineness of 300 mesh; mix at a low speed according to the ratio of 1:1:1 to obtain 56.5 parts of waste mineral powder d, and then couple with 3.5 parts of aluminate Agent distearoyloxyisopropyl aluminate, under the condition of 80°C, stir and mix at 800 rpm for 30min, cool to 40°C, stop stirring to obtain modified waste mineral powder.

[0041] 2) Mix the modified waste mineral powder with 1 part of stearic acid and 2 parts of paraffin wax respectively, raise the temperature to 100°C, stir vigorously for 1 hour, cool to 40°C, stop stirring to obtain the modified waste mineral powder premix.

[0042] 3) Mix the modified waste mineral powder premix with 25 parts of PVC resin powder, 6 parts of PVC calcium-zinc composite stabilizer, 3 parts ...

Embodiment 2

[0044] Prepare PVC composite materials according to the following raw materials:

[0045]

[0046]

[0047] Specific implementation steps:

[0048] 1) Grind waste mineral powder a, waste mineral powder b and waste mineral powder c to a fineness of 300 mesh; mix at a low speed according to the ratio of 1:1:1 to obtain 58.5 parts of waste mineral powder d, and then couple with 1.5 parts of aluminate agent, under the condition of 80°C, stir and mix at 800 rpm for 30min, cool to 40°C, stop stirring to obtain modified waste mineral powder.

[0049] 2) Mix the modified waste mineral powder with 1 part of paraffin respectively, raise the temperature to 100°C, stir for 1 hour with strong mechanical force, cool to 40°C, stop stirring to obtain the modified waste mineral powder premix.

[0050] 3) Mix the modified waste mineral powder premix with 20 parts of PVC resin powder, 3 parts of PVC calcium-zinc composite stabilizer, 3 parts of ACR toughening agent and 3 parts of CPE, hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com