Pollen pini drying and sand-impurity-removing method

A pine pollen and drying technology, which is applied in food preservation, food preparation, food science, etc., can solve the problems of difficult control of pine pollen moisture, high temperature, and damage, and achieve the effect of large-scale continuous operation and rapid drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to better understand the present invention, it will be further elaborated below in conjunction with the accompanying drawings and embodiments.

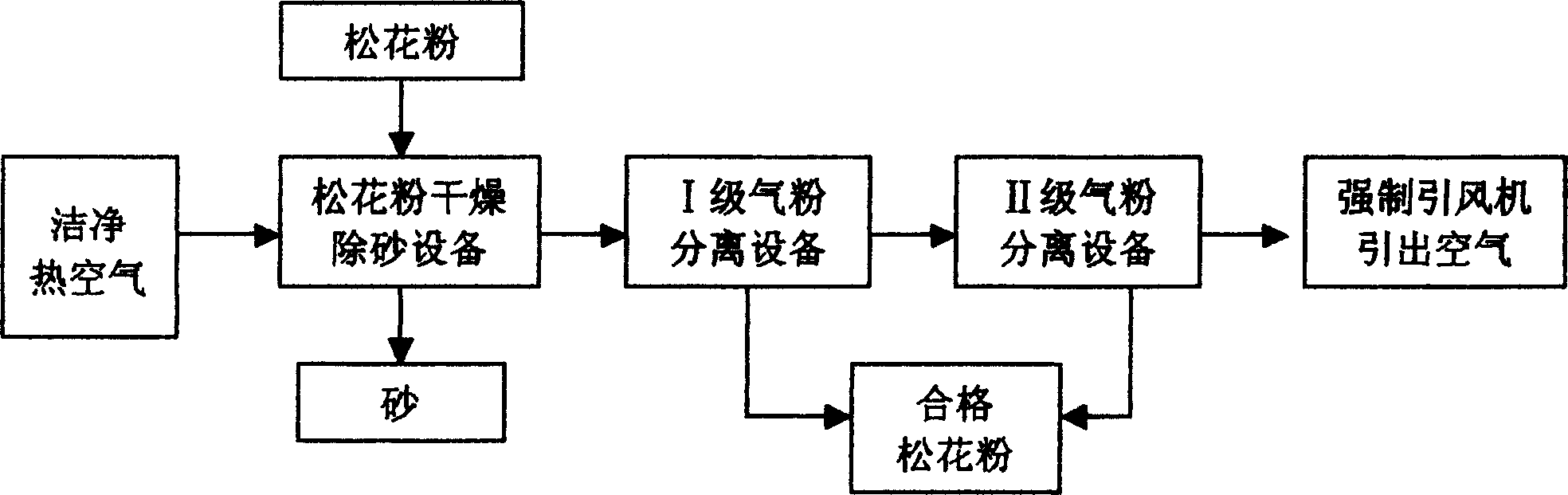

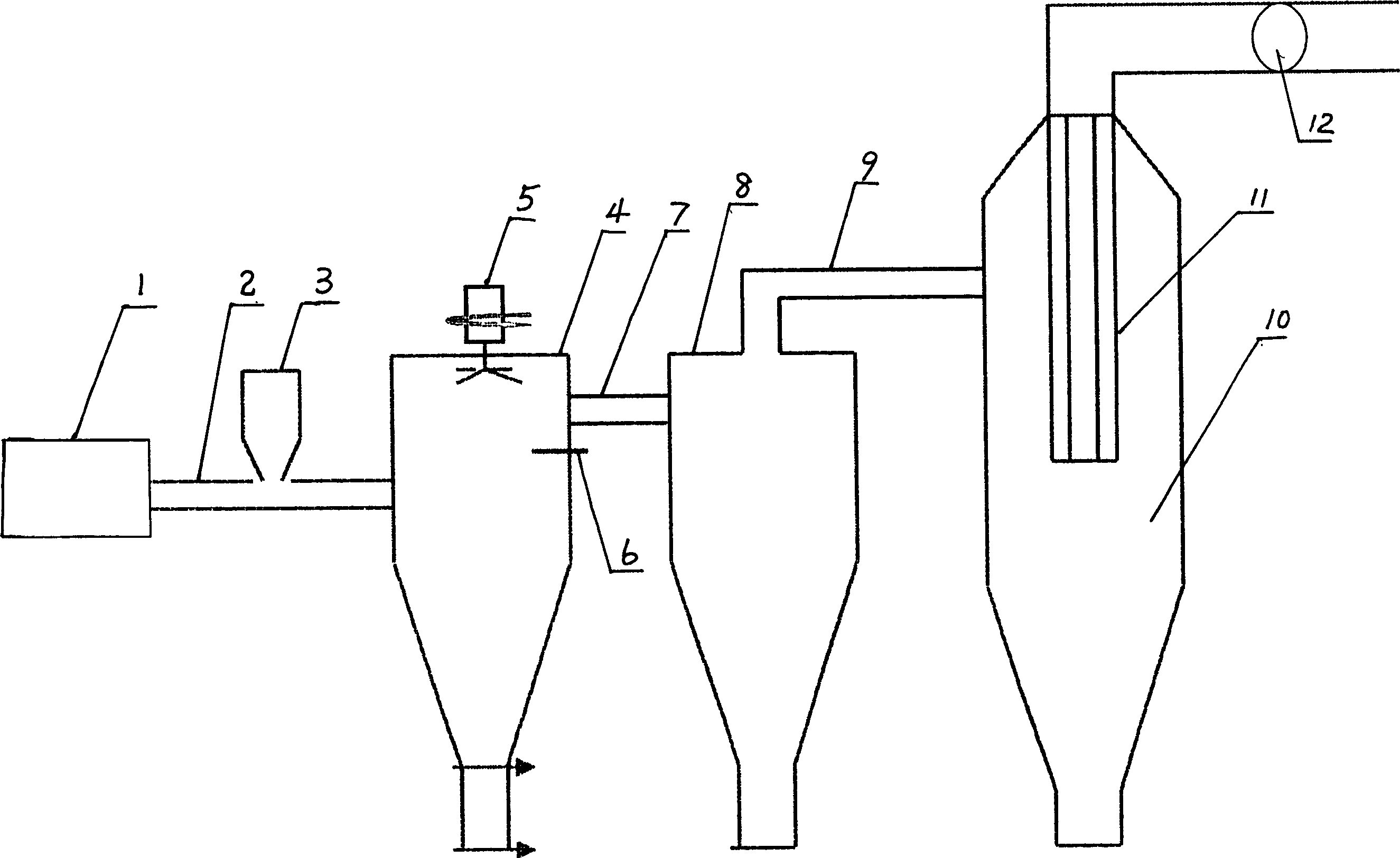

[0009] refer to figure 1 , figure 2 , the pine pollen drying desanding and impurity removal method of the present invention is followed successively: 1, purification and heating of air: this process is finished in air purification and heater 1, because pine pollen is the raw material of food and health food, Therefore, the air before heating needs to be purified; because pine pollen is rich in nutrients, some nutrients are easily destroyed at high temperatures, so the temperature of the hot air is designed to be adjustable to ensure that the surface temperature of the pine pollen material during the drying process is not high. Above 60°C, the adjustable temperature range of the hot air is 80-150°C; 2. Dry sand and impurity removal: the above-mentioned hot air is attracted by the forced induced draft fan 12, and enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com