Automatic gear shift control system and method of motor-transmission integrated drive system for electrical vehicle

An electric vehicle and automatic shifting technology, which is applied in the field of automatic shifting control systems, can solve the problems of complex coordination and control of transmissions and shifting actuators, shifting shocks, and easy noise generation, and achieve simplified automatic shifting control systems, Effect of suppressing shift shock and noise and improving controllability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

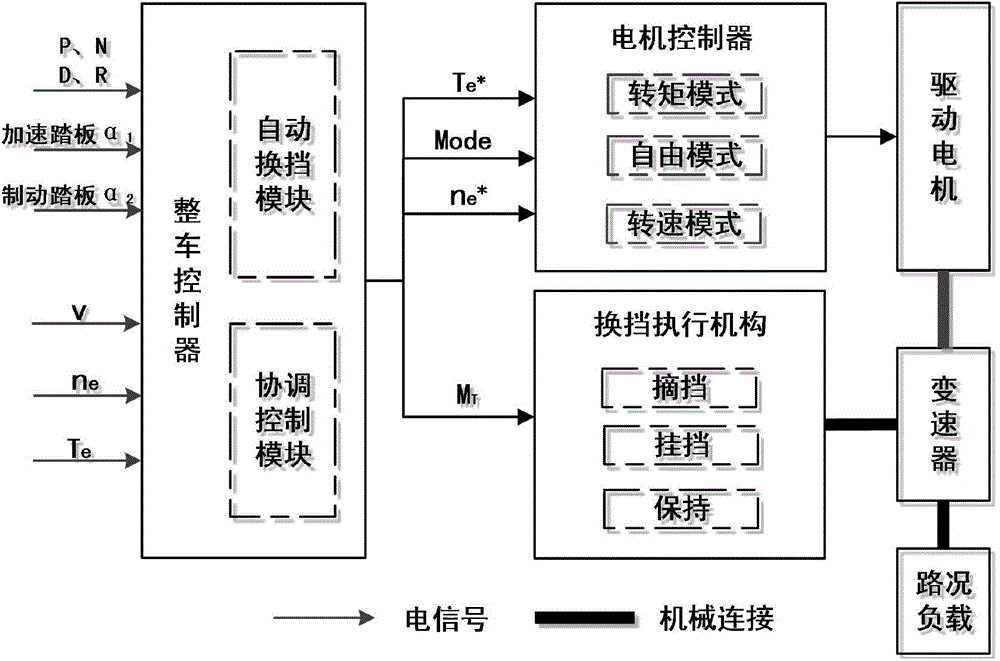

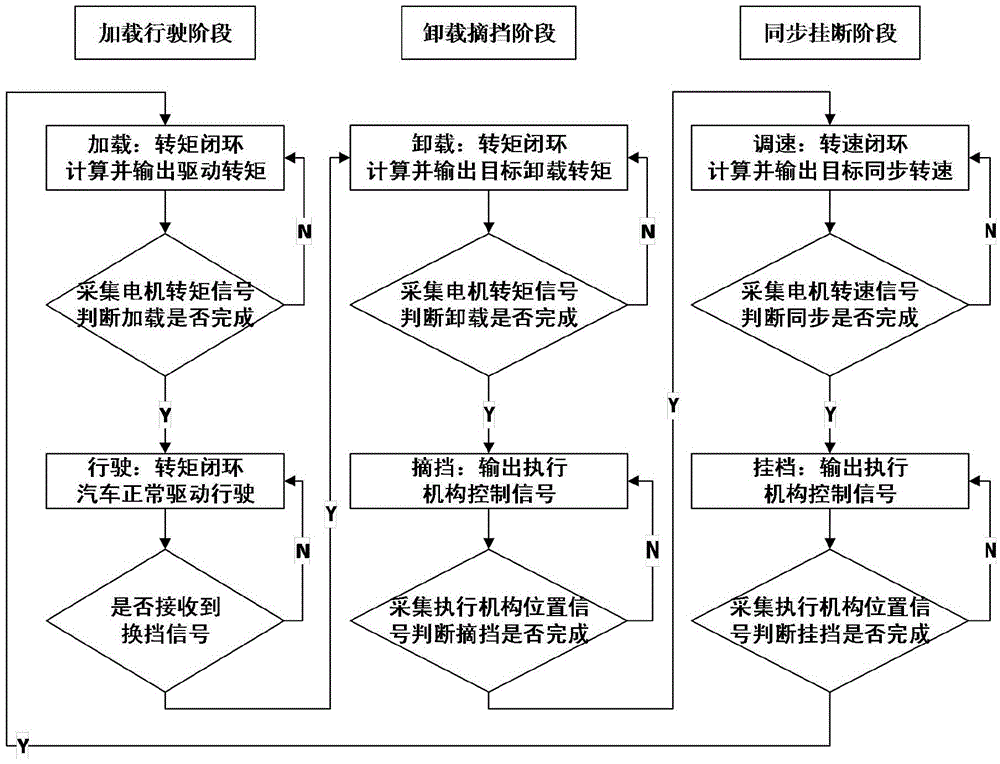

[0039] Such as figure 1As shown, the composition of the motor-transmission integrated drive system for electric vehicles in the automatic shift control system of the motor-transmission integrated drive system for electric vehicles includes: drive motor, transmission, motor controller and shift actuator; drive The clutch is omitted between the motor and the transmission, which are directly connected by splines, and the motor controller controls the output torque of the driving motor to the transmission, and the shift actuator is used to complete the shift operation of the transmission.

[0040] On the basis of the motor-transmission integrated drive system for electric vehicles, a vehicle controller is set up, and the motor controller and the shift actuator are coordinated and controlled by the vehicle controller, so as to realize the automatic shift function of the motor-transmission integrated drive system ; The automatic shift control system is composed of the vehicle contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com