Power transmission fluids with enhanced lifetime characteristics

a technology of transmission fluid and lifetime characteristics, which is applied in the direction of lubricant composition, mechanical equipment, and gearing details, etc., can solve the problems of increasing the compressibility of oil, increasing the tendency of shifting times, and requiring performance changes, so as to reduce the surface tension of fluid, increase the ability of fluid to release air, and reduce the tendency of fluid to foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

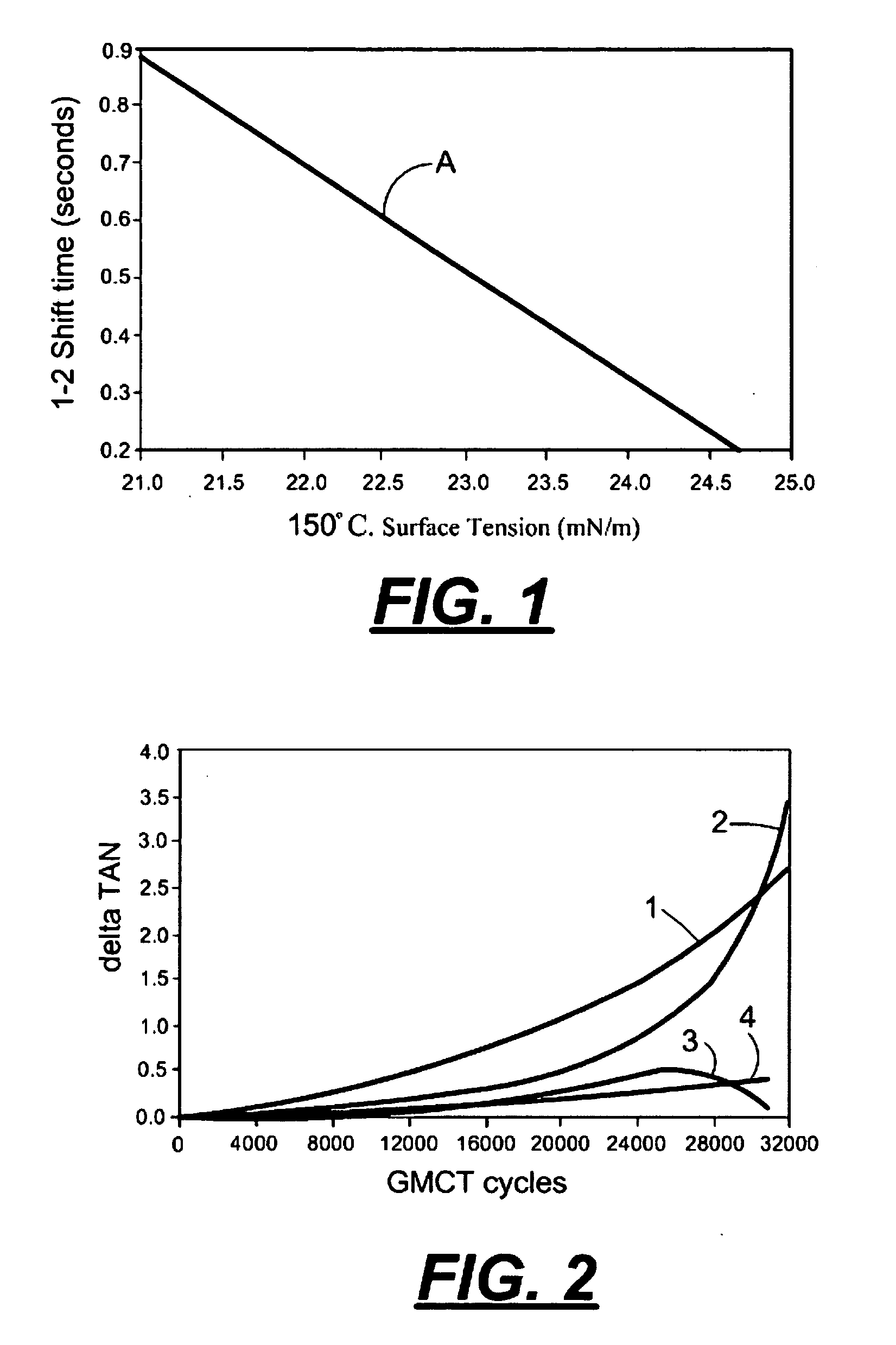

[0016] The disclosed embodiments use an antifoam agent having unconventionally high kinematic viscosity for ATF applications. The antifoam agent may be used in a fully formulated ATF or may be directly injected as a top treat into the ATF in the transmission to reduce clutch engagement times. In an exemplary embodiment, the ATF also contains an optional air release agent. The disclosed embodiments also include an additive system containing the aforementioned unconventionally high viscosity antifoam agent, which may be mixed with other compositions by ATF formulators for providing an ATF.

[0017] Suitable silicon-containing antifoam agents according to the disclosure include, but are not limited to, fluorosilicones, polydimethylsiloxane, phenyl-methyl polysiloxane, linear siloxanes, cyclic siloxanes, branched siloxanes, silicone polymers and copolymers, organo-silicone copolymers, and mixtures thereof. Such antifoam agents have a kinematic viscosity at 25° C. of greate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com