Double clutch type automatic gearbox

A technology of automatic transmission and double clutch, applied in the direction of transmission, joint control, transmission control, etc., to achieve the effect of improving shifting comfort, shortening shifting time, and good power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention are further described in detail in the following embodiments given in conjunction with the accompanying drawings.

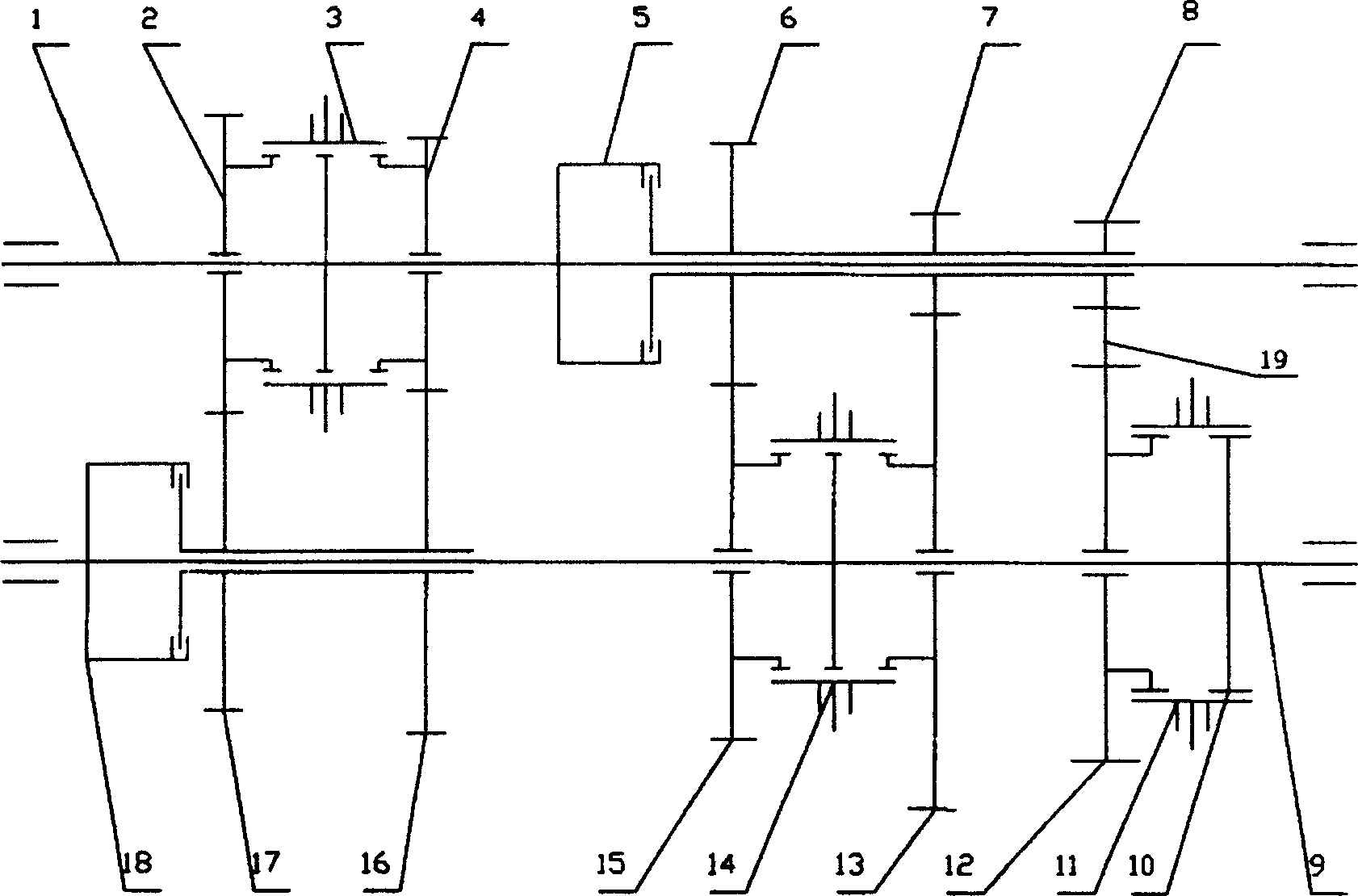

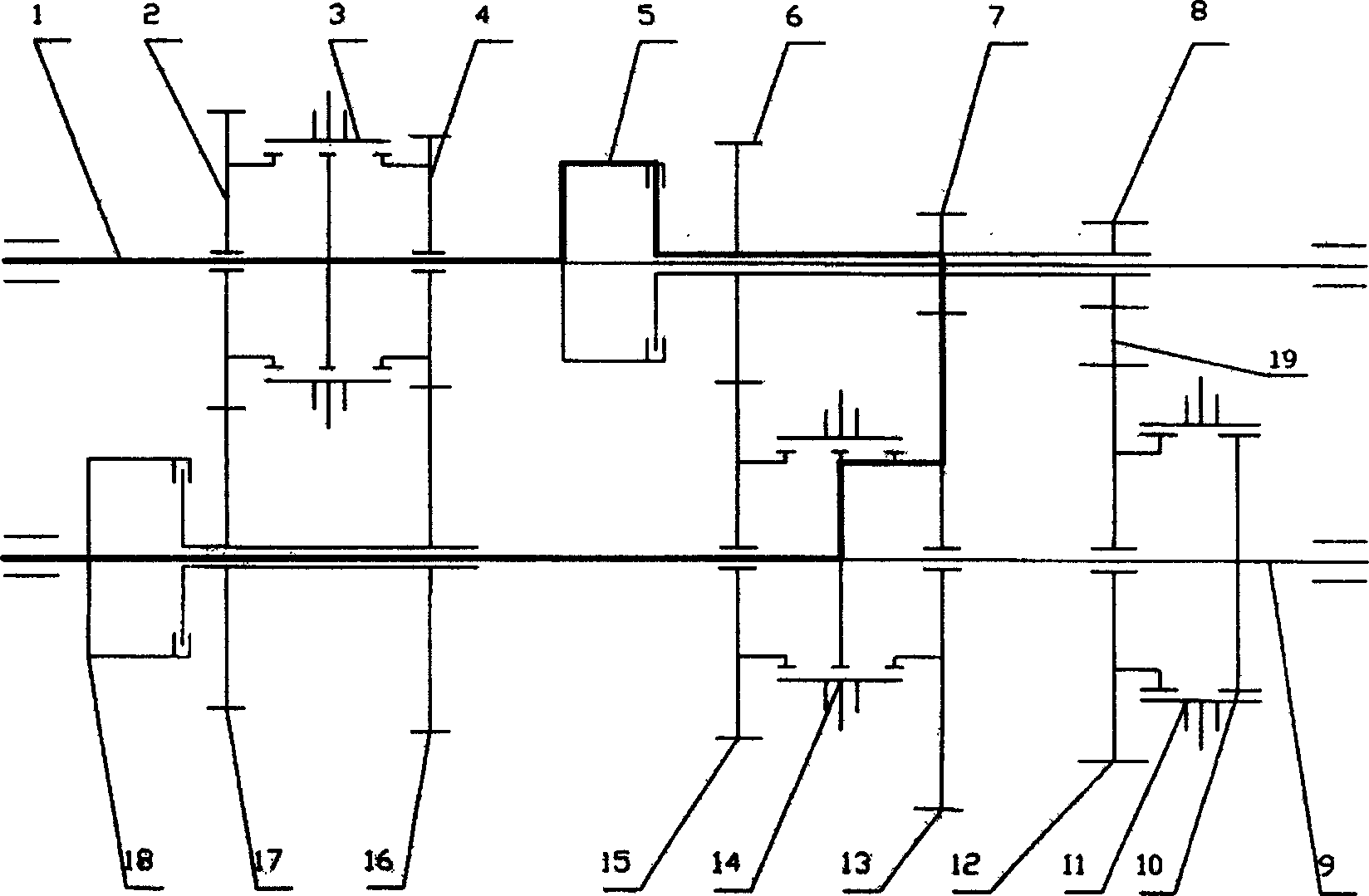

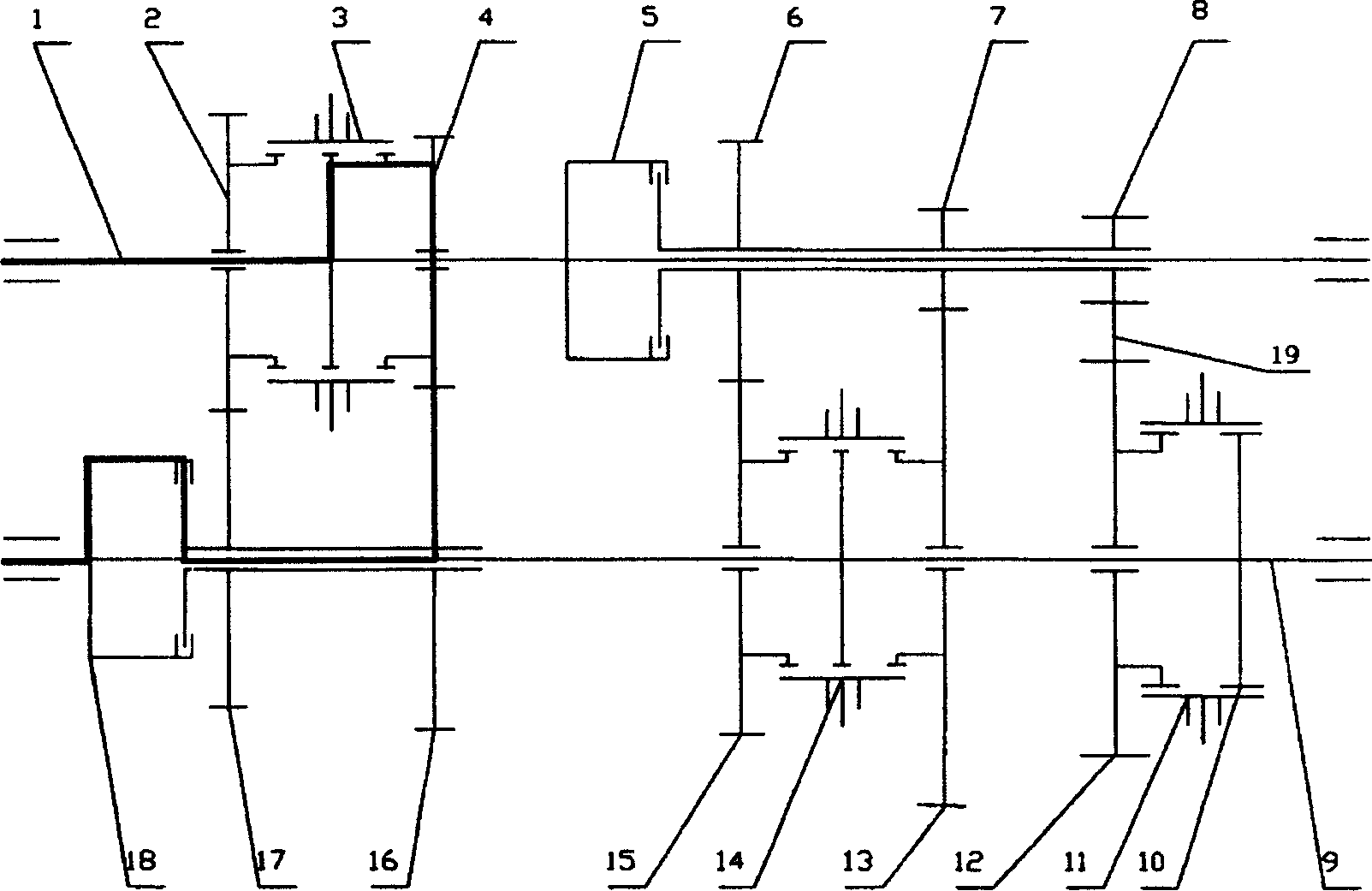

[0018] Figures 1 to 3 Middle: 1 is the input shaft, 2 is the driving gear of fourth gear, 3 is the synchronizer of second gear and fourth gear, 4 is the driving gear of second gear, 5 is the clutch of first gear, third gear and reverse gear, 6 is the driving gear of third gear, and 7 is one gear 8 is the driving gear for reverse gear, 19 is the intermediate gear for reverse gear, 9 is the output shaft, 10 is the coupling ring gear for reverse gear, 11 is the coupling sleeve for reverse gear, 12 is the driven gear for reverse gear, and 13 is the first gear Driven gear, 14 is first and third gear synchronizers, 15 is third gear driven gear, 16 is second gear driven gear, 17 is fourth gear driven gear, and 18 is second and fourth gear clutches.

[0019] refer to figure 1 , a dual-clutch automatic transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com