Automatic gear shift mechanism for transmission

An automatic shifting and transmission technology, applied in mechanical equipment, components with teeth, transmission control and other directions, can solve problems such as inaccurate gear positions, inability to perform shifting operations, and easy damage to the synchronizer of the shifting mechanism. Reliable shifting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

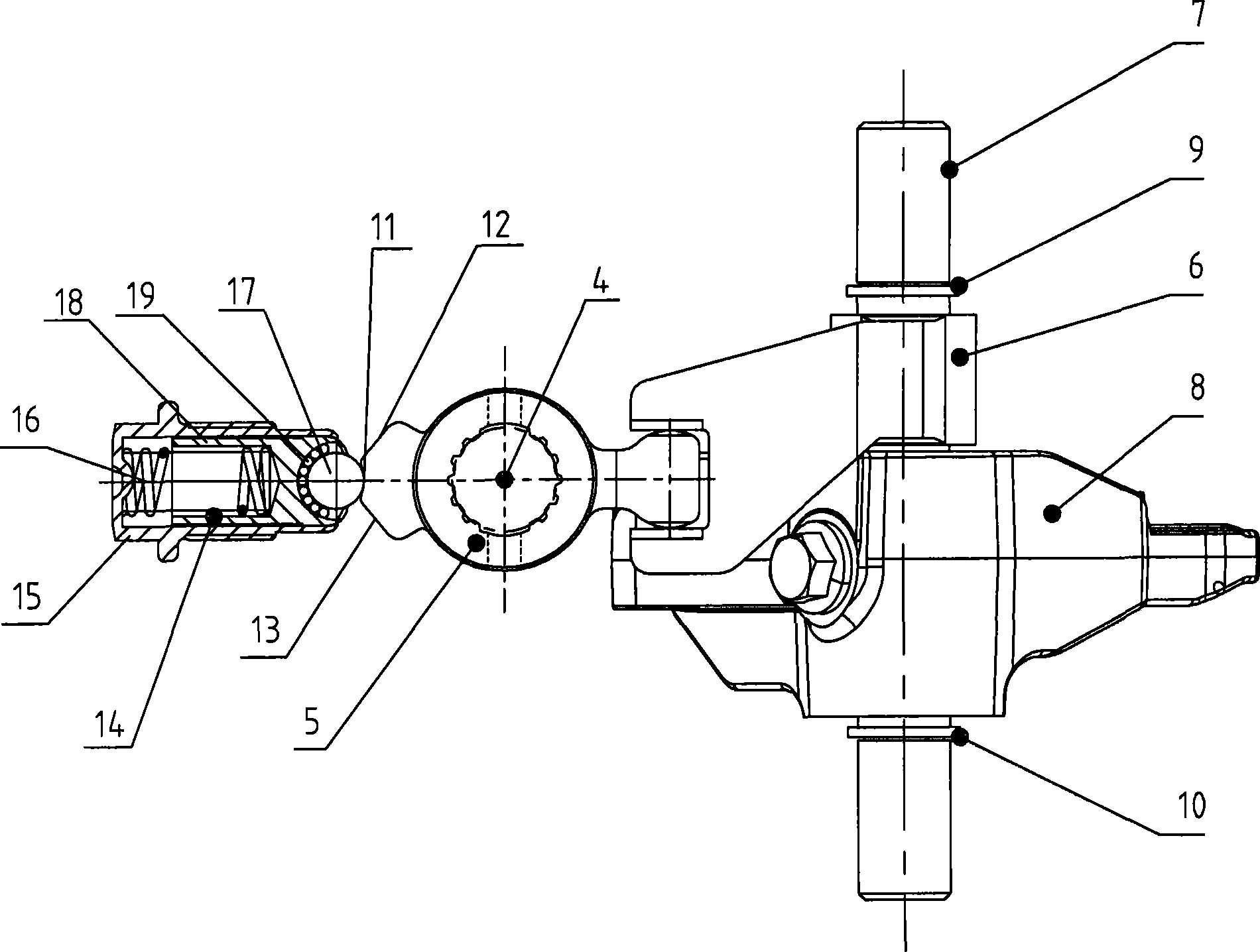

[0019] According to one embodiment, the gear position limiting device may include a first limit stop ring 9 and a second limit stop ring 10 respectively fixed at both ends of the shift fork shaft 7, such as image 3 shown. When the transmission is in the driving gear, the first limit retaining ring 9 or the second limit retaining ring 10 will be blocked by the transmission case (not shown), so as to prevent gear shift overshoot. For example, during the axial movement of the shift fork shaft 7, when the synchronizer (i.e. the synchronizer gear sleeve) moves to the first gear position, the first stop ring 9 will be blocked by the transmission case; when the synchronizer gear sleeve When moving to the second gear position, the second limit retaining ring 10 will be blocked by the transmission case.

[0020] The first limit retaining ring 9 and the second limit retaining ring 10 can be located inside the transmission case, or outside the transmission case. If the first limit ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com