Automatic gear-shifting control method and system for two-gear transmission of electric vehicle

A technology of automatic gear shifting and control methods, which is applied in transmission control, components with teeth, belts/chains/gears, etc., and can solve slow-down torque, slow-up torque, long shift time, medium-high speed performance without consideration Improve vehicle drivability, increase maximum vehicle speed, and shorten shift time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

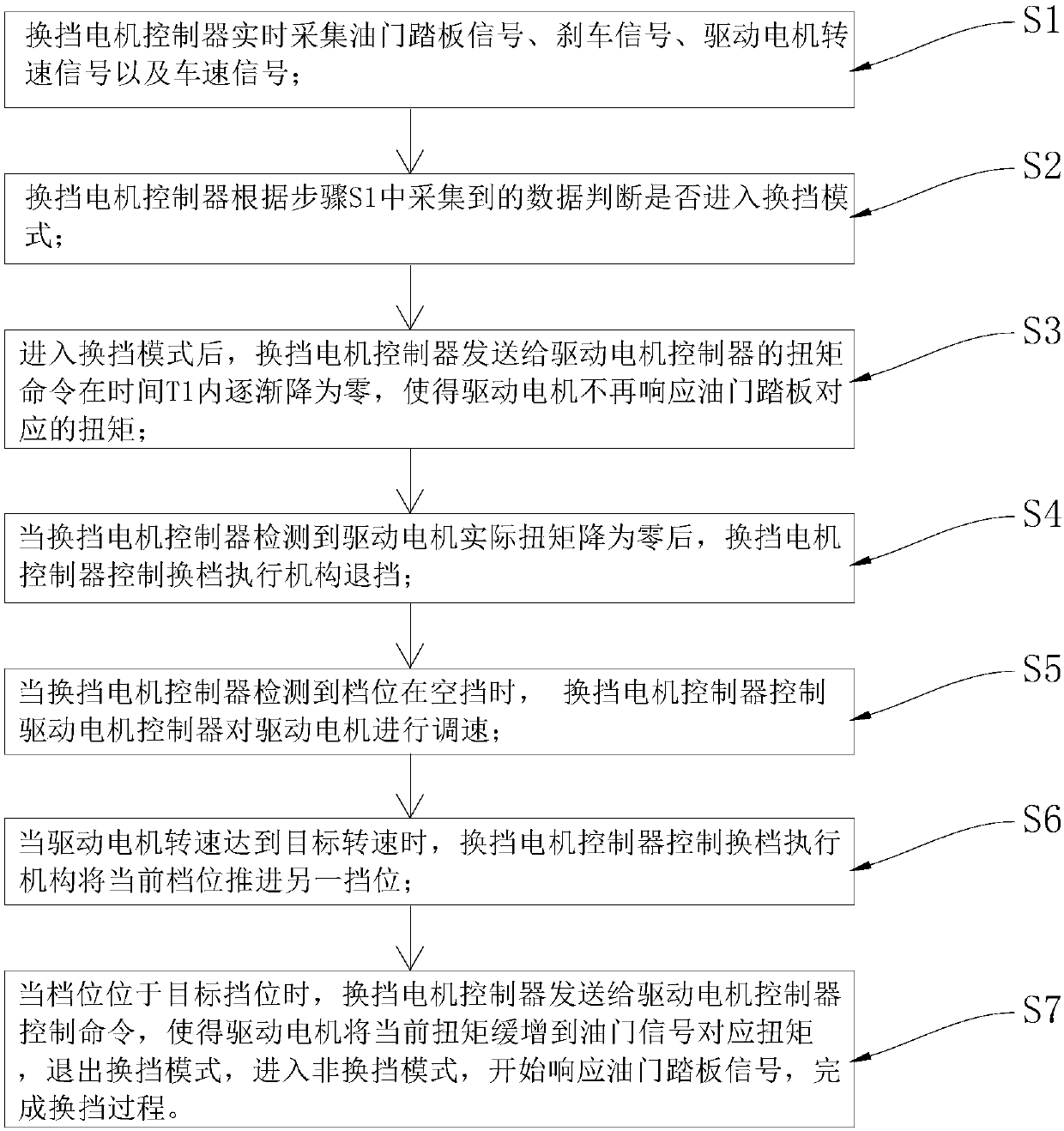

[0051] Such as figure 1 As shown, the electric vehicle two-speed gearbox automatic shift control method of the present invention comprises the following steps:

[0052] S1: The shift motor controller collects the accelerator pedal signal, brake signal, driving motor speed signal and vehicle speed signal in real time;

[0053] S2: the shift motor controller judges whether to enter the shift mode according to the data collected in step S1;

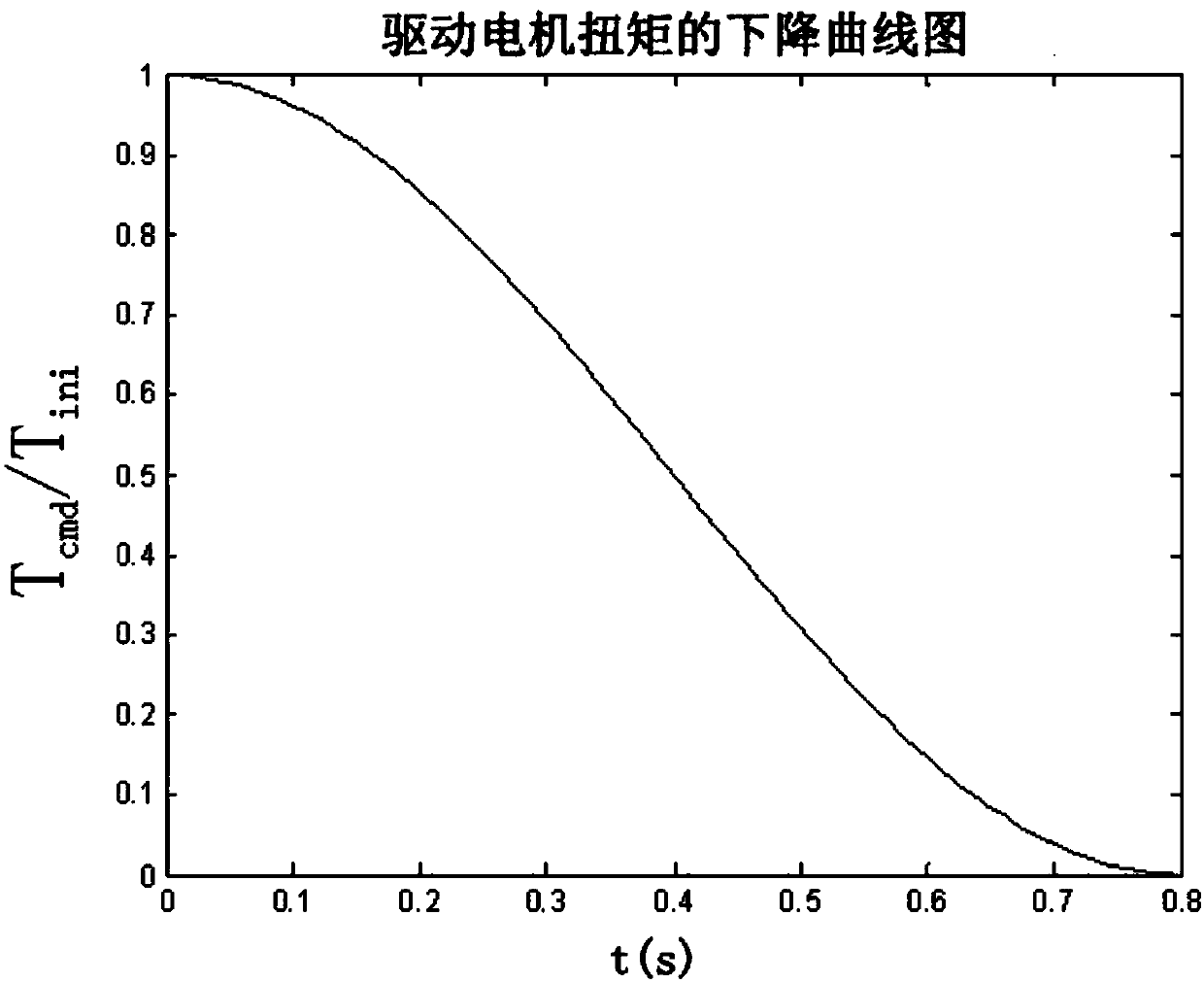

[0054] S3: After entering the shift mode, the torque command sent by the shift motor controller to the drive motor controller gradually decreases to zero within the time T1, so that the drive motor no longer responds to the torque corresponding to the accelerator pedal;

[0055] S4: When the shift motor controller detects that the actual torque of the drive motor has dropped to zero, the shift motor controller controls the shift actuator to back up;

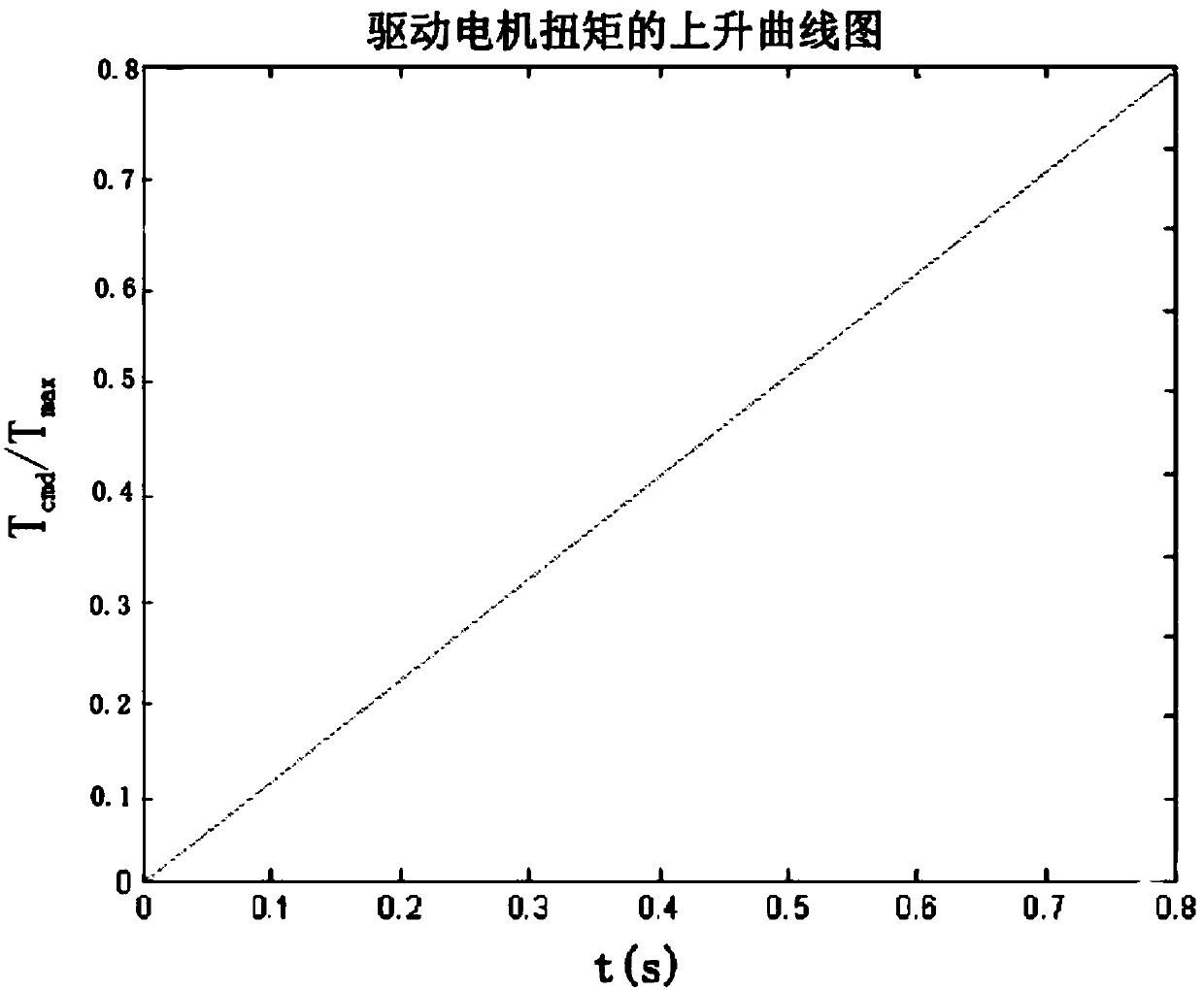

[0056] S5: When the shift motor controller detects that the gear is in neutral, the shift...

Embodiment 2

[0097] Such as Figure 4 As shown, the automatic shift control system of the electric vehicle two-speed gearbox of the present invention includes a vehicle controller, a shift motor controller, a shift actuator, a drive motor controller, a drive motor and a two-speed gearbox. The gear motor controller is respectively connected to the vehicle controller and the drive motor controller through the CAN bus, the drive motor controller is connected to the drive motor, the shift motor controller is also connected to the shift actuator, and the shift actuator is mechanically connected to the two-speed gearbox .

[0098] The working principle of embodiment 2 is: during the shifting process, the shifting motor controller takes over the control of the driving motor controller, cooperates to complete the entire shifting action, the shifting motor controller is connected to the vehicle controller, and collects vehicle control information. According to the information of the vehicle in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com