Seven-speed double-clutch hybrid power transmission device

A dual-clutch, hybrid power technology, applied to the arrangement of multiple prime movers of power plants, pneumatic power plants, and general-purpose power plants, can solve problems such as complex structures, achieve high transmission efficiency, and reduce mechanism complexity , Reduce the effect of shifting frustration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

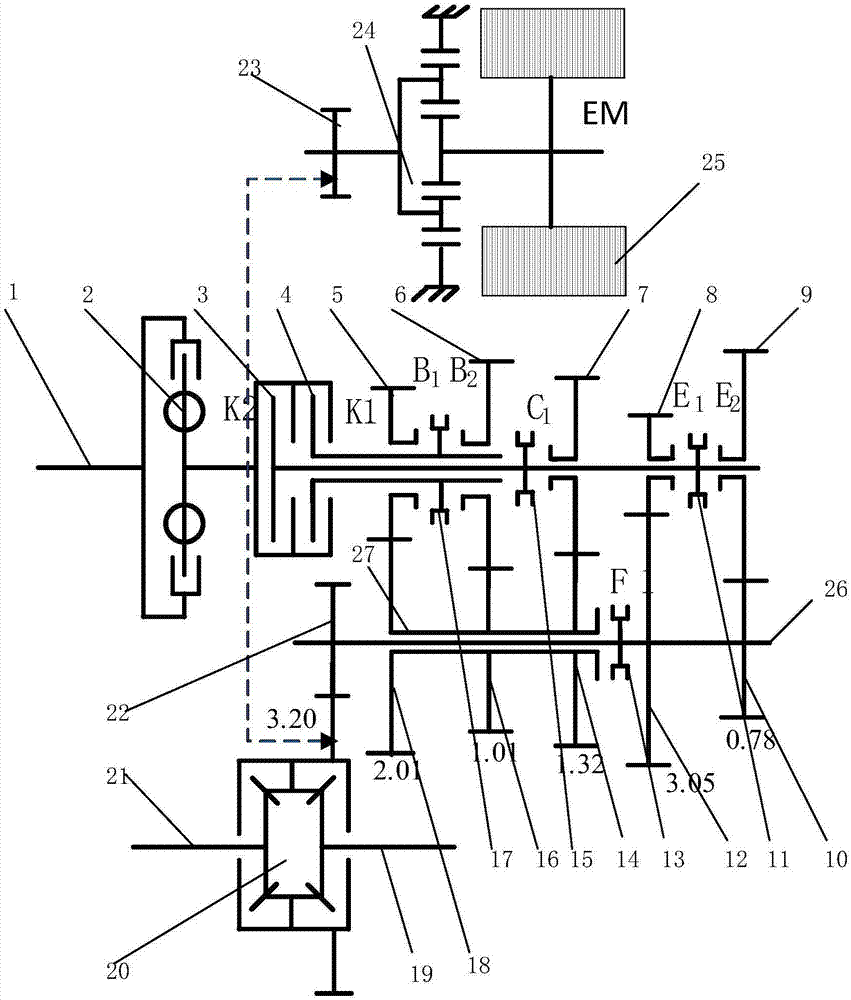

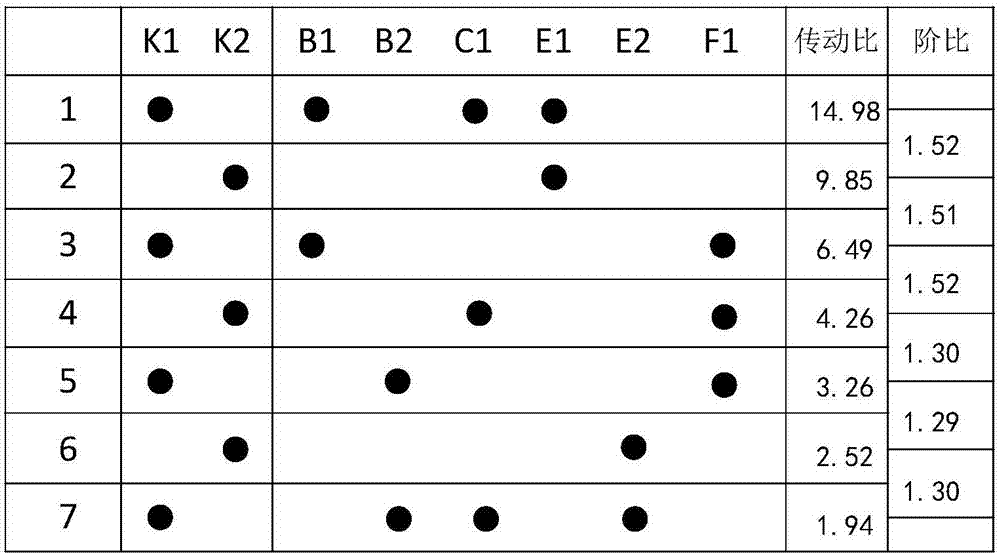

[0014] Embodiment 1: see attached figure 1 , a seven-speed dual-clutch hybrid transmission, which includes: engine input shaft 1, shock absorber 2, K2 clutch 3, K1 clutch 4, first gear 5, second gear 6, twelfth gear 7, the first Third gear 8, fourth gear 9, fifth gear 10, E synchronizer 11, sixth gear 12, F synchronizer 13, seventh gear 14, C synchronizer 15, eighth gear 16, B synchronizer 17, first gear Nine gears 18, differential gear 20, tenth gear 22, eleventh gear 23, reduction planetary row 24, motor 25, first shaft 26, second shaft 27;

[0015] The K2 clutch 3 and the K1 clutch 4 are coaxially arranged, and the two clutches can be nested in the radial direction or arranged side by side in the axial direction to form a dual-clutch module to switch engine power; the first gear 5 and the second gear 6 The empty sleeve is on the output shaft of the K1 clutch 4, and the B synchronizer 17 is fixed on the output shaft of the K1 clutch 4, and is located between the first gear ...

Embodiment 2

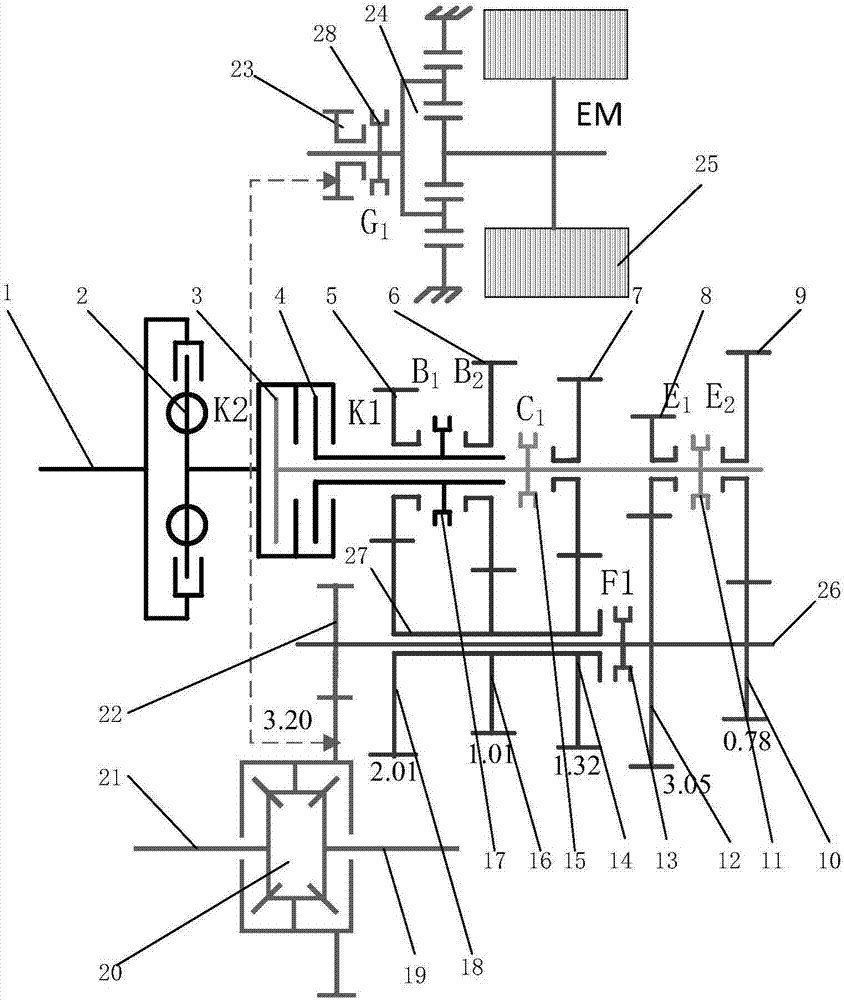

[0034] Embodiment 2: On the basis of Embodiment 1, a G synchronizer 28 is added; the G synchronizer 28 is used to realize the synchronization of the eleventh gear 23 and the deceleration planetary row 24 planet carrier, and when the vehicle speed is greater than 120km / h, G synchronization The device 28 is disconnected, reducing the high-speed drag torque.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com