Two-gear mechanical vehicle transmission

A technology of automobile transmission and second-gear machinery, which is applied in mechanical equipment, mechanical control devices, instruments, etc., can solve the problems of increased cost, large speed range requirements, increased power consumption, etc., and achieves low comprehensive power consumption and improved gear shifting. Comfort, small width effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

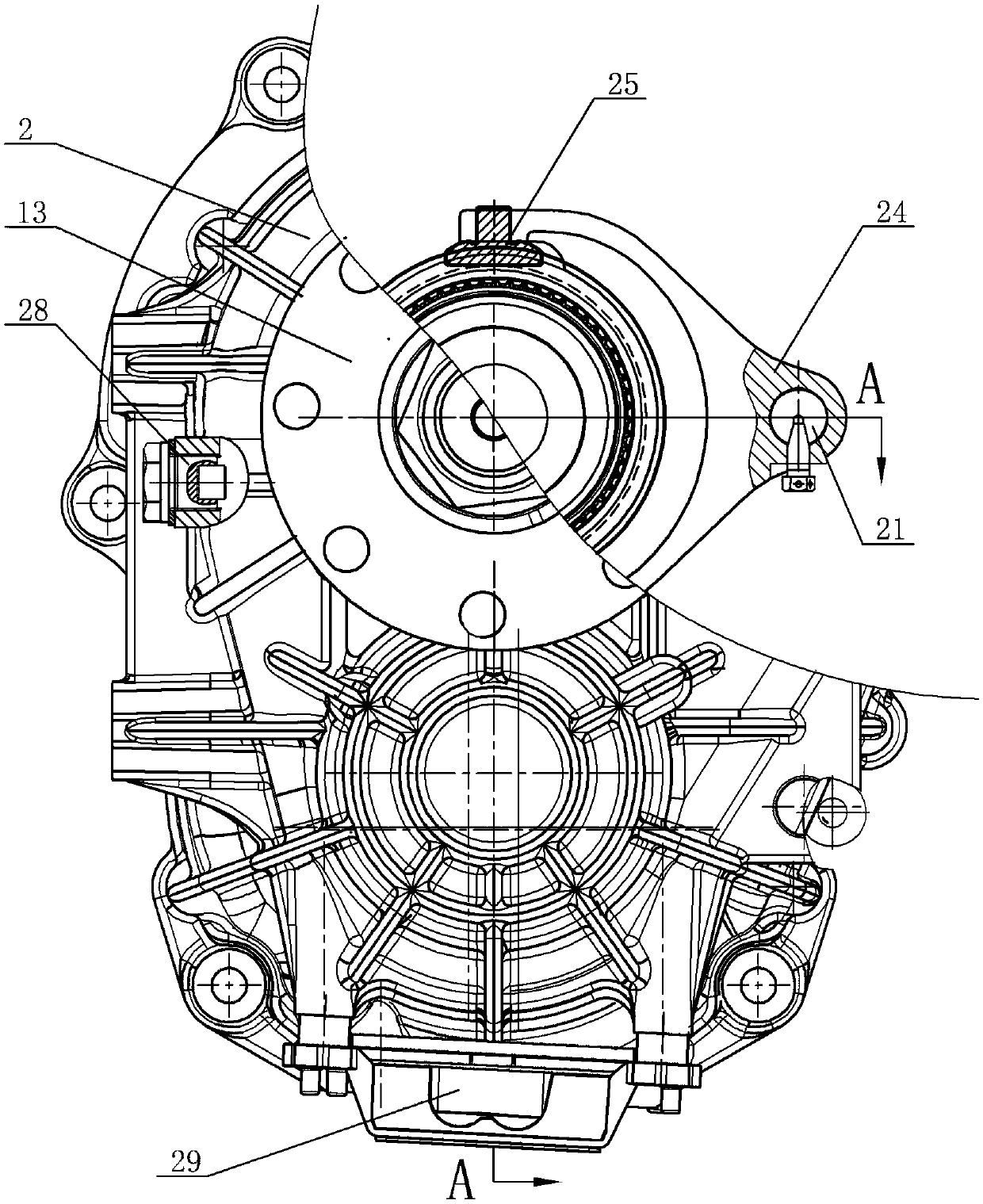

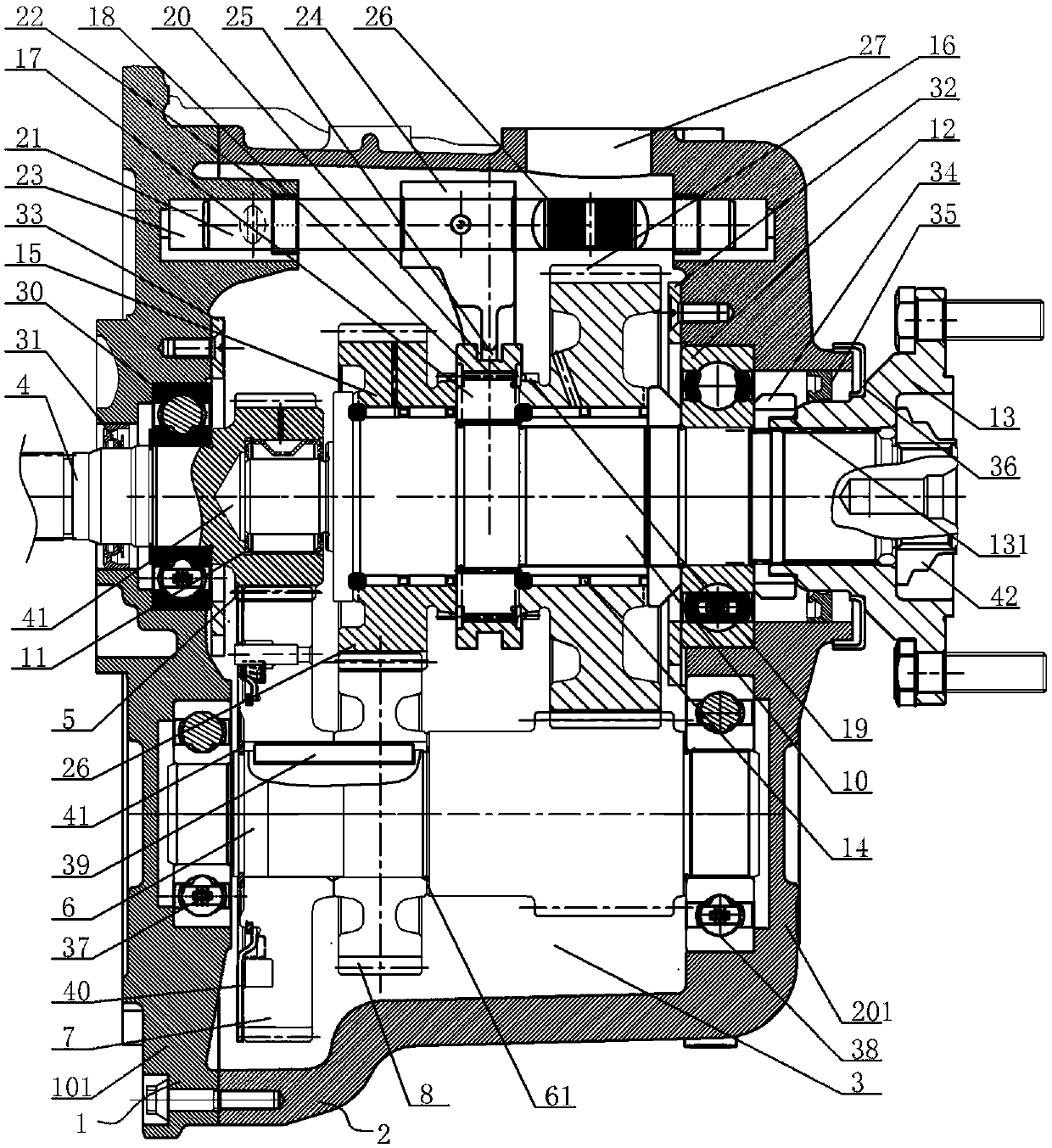

[0017] A two-speed mechanical automobile transmission, see figure 1 , figure 2 : It includes a first shell 1 and a second shell 2, the rear end cover of the first shell 1 is equipped with the second shell 2, the first shell 1 and the second shell 2 are combined to form an installation cavity 3, the second shell The front end wall 101 of a casing 1 is provided with a protruding first shaft 4, the inner end of the first shaft 4 goes deep into the front end area of the installation cavity 3, the protruding end of the first shaft 4 is externally connected to a drive motor, and the first shaft 4 The outer ring surface of the inner end of the inner end is covered with a shaft constant meshing gear 5, and an intermediate shaft 6 is arranged between the front end wall 101 and the rear end wall 201 of the installation chamber 3, and the intermediate shaft 6 is arranged in parallel directly below the first shaft 4, and the intermediate shaft The outer ring surface of 6 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com