DCT speed changer shifting fork gear engaging controlling method

A control method and transmission technology, applied in transmission control, clutches, components with teeth, etc., can solve the problems affecting the quality of shifting forks, and achieve the improvement of shifting quality and comfort, noise and vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

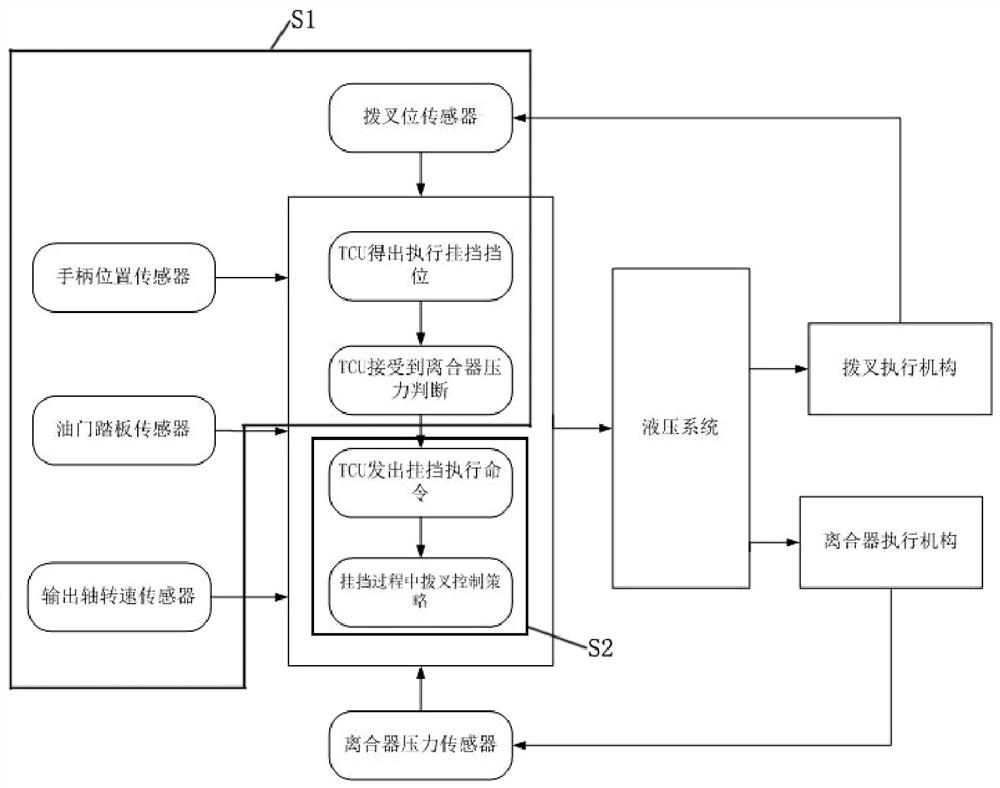

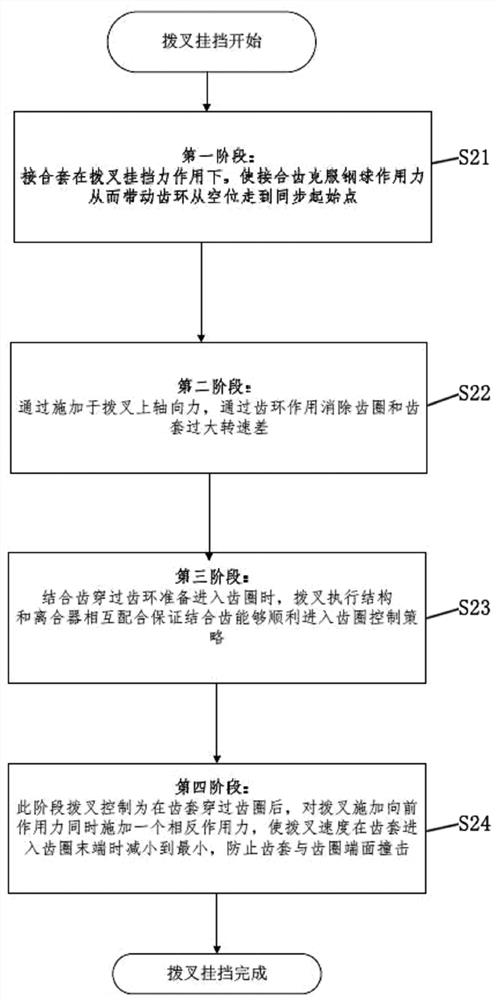

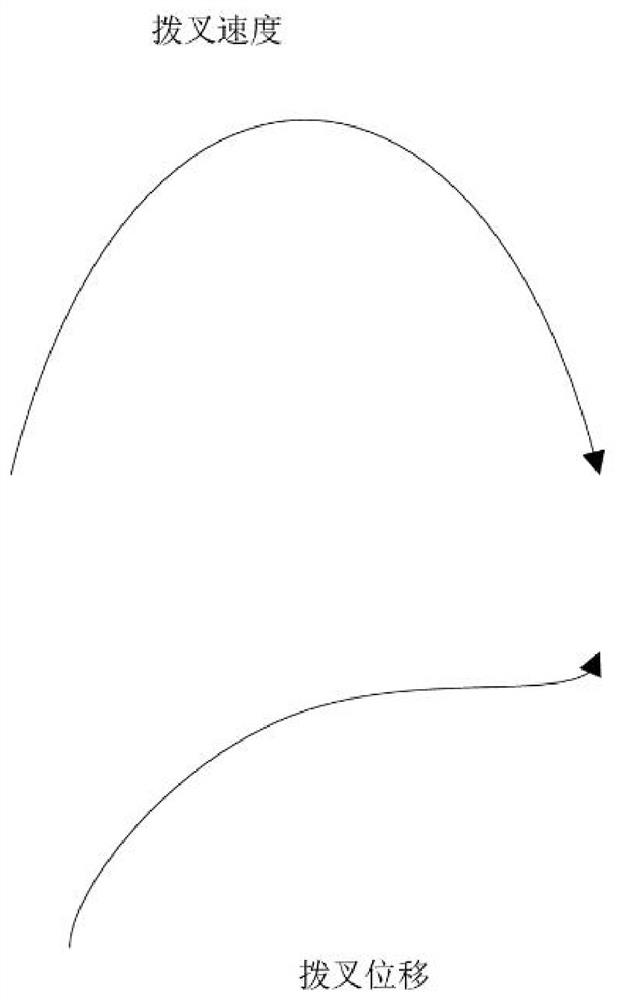

[0033] Such as figure 1 , DCT speed changer gear shifting control method, comprises the following steps:

[0034] S1, the TCU issues a command to execute the gear; before the TCU issues the command to execute the gear, the following preparations need to be made:

[0035] (1) Determine the gear to be engaged. The gear to be engaged is determined by the target gear and the pre-selected gear, and the target gear has priority over the pre-selected gear. The target gear is calculated by the output shaft speed, throttle opening and handle position, and the preselected gear is determined by the target gear and the throttle.

[0036] (2) Determine the gear sleeve speed of the gear synchronizer. The gear sleeve speed is calculated from the differential end speed, that is, the output end speed and speed ratio. The output end speed is calculated from the vehicle speed and tir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com