Three-conical-face synchronizer with lubricating oil way

A lubricating oil circuit and synchronizer technology, which is applied in the direction of engine lubrication, clutches, couplings, etc., can solve the problems of accelerating the early wear and failure of three-cone synchronizers, increasing manufacturing costs, and long shifting time. The driver's operation is comfortable and light, the service life is improved, and the shifting time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

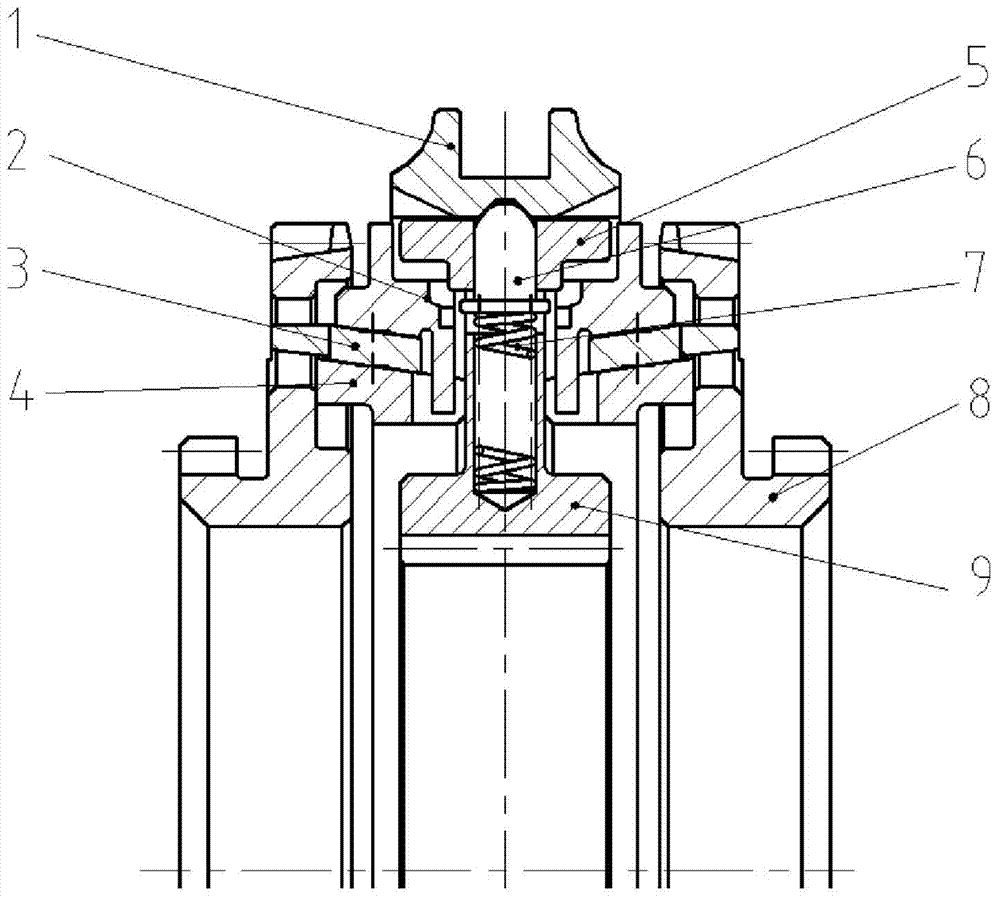

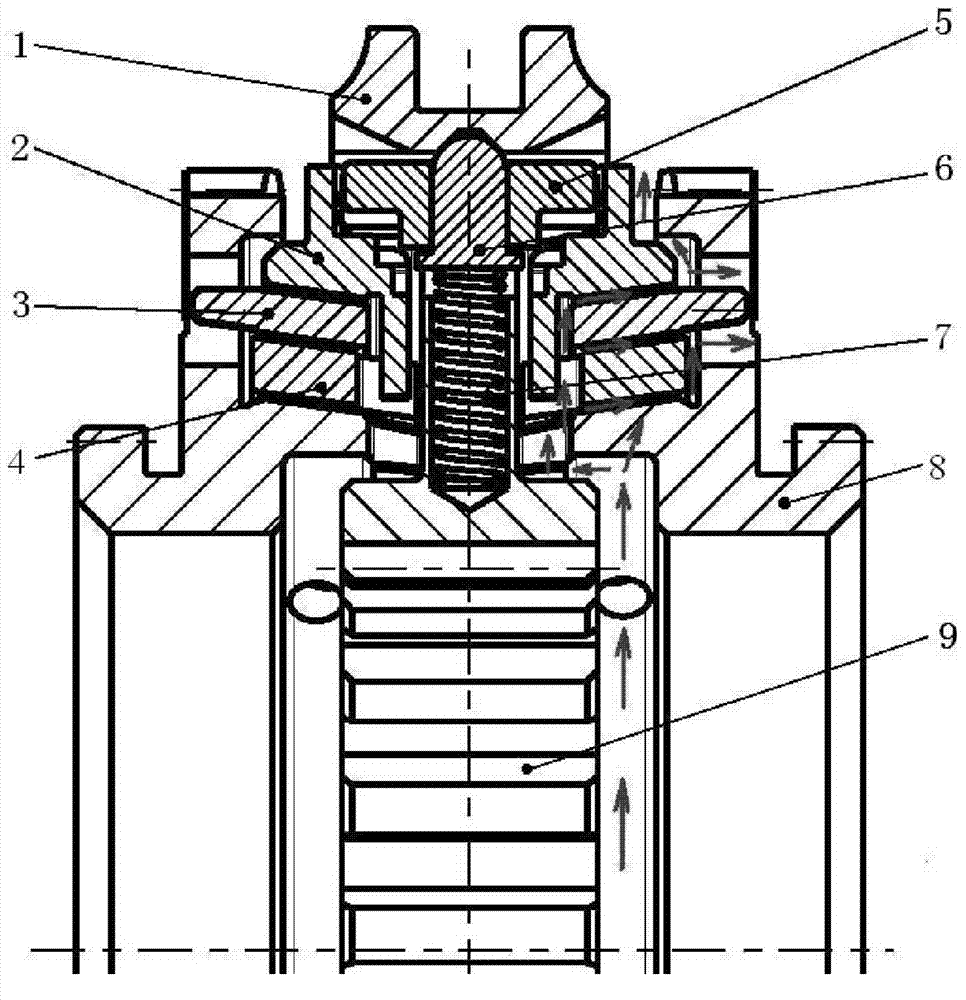

[0023] see Figure 2-5 , a three-cone synchronizer with a lubricating oil passage in the present invention, including a sliding tooth sleeve 1, a pair of outer friction rings 2, a pair of friction intermediate rings 3, a pair of inner friction rings 4, a slider 5, a pin 6, Spring 7, a pair of combined ring gear 8 and gear hub 9;

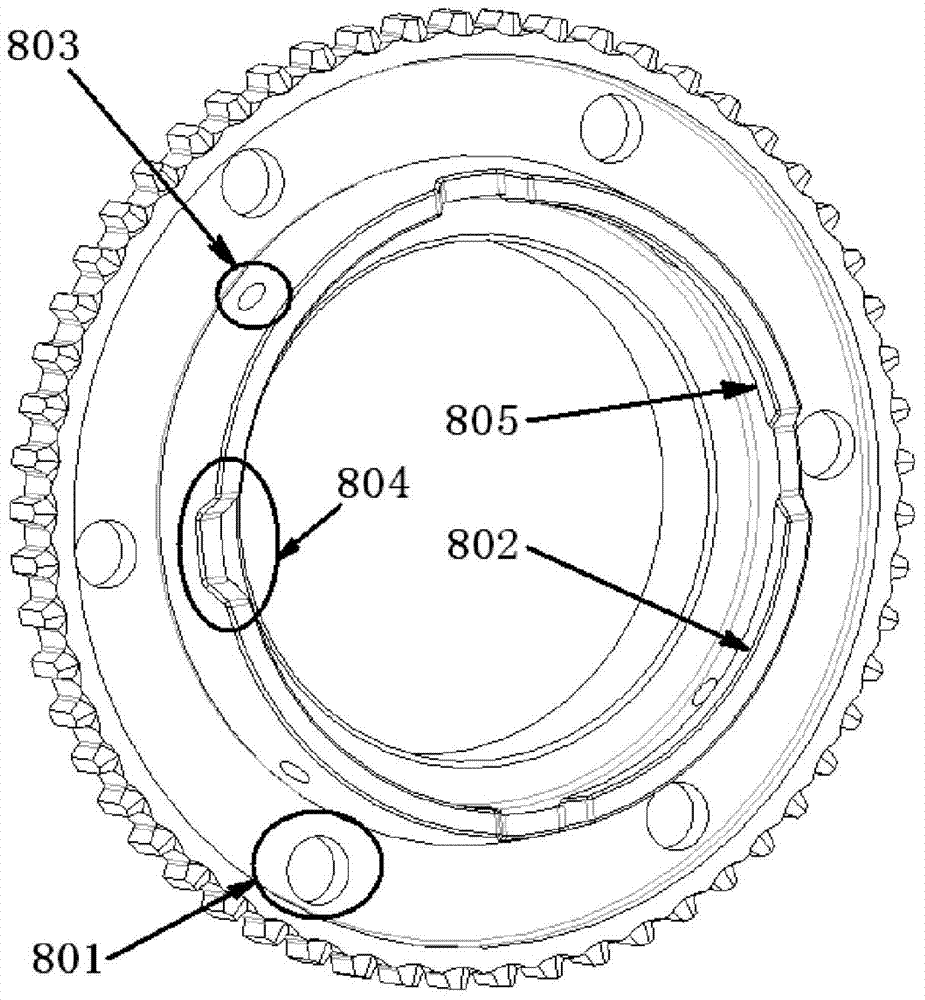

[0024] Among them, the inner ring of the outer friction ring 2 is provided with 6 first claws 201 in the circumferential direction, and the inner friction ring 4 is provided with 6 oil passage grooves 401 matching with the 6 first claws 201 in the circumferential direction. There are 6 oil holes 801 arranged in the circumferential direction, and a conical body 802 is arranged on the end surface, and 4 oil holes 803 and 4 radial oil grooves 804 are arranged in the circumferential direction of the conical body 802, and the radial oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com