Tractor load reversing transmission device

A technology of reversing transmission and reversing device, which is applied in the field of tractors, can solve the problems of not being able to meet the needs of users, the driver's uncomfortable handling, impact and large operating force, etc., and achieve improved operating comfort, compact structure, and small shifting impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

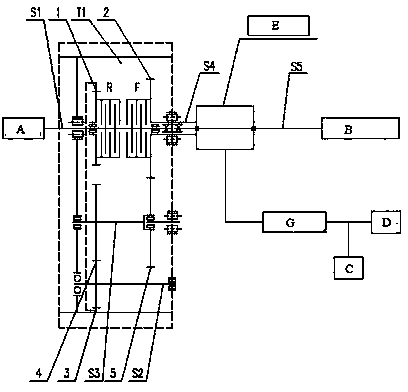

[0009] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings. like figure 1 As shown, the gearbox consists of three parts: the load reversing device T1, the main transmission device E, and the auxiliary transmission device G. One end of the load reversing device T1 is connected with the engine A, and the other end is connected with the main transmission device E.

[0010] The input shaft S1, the reversing driven gear shaft S3, and the reversing idler shaft S2 are installed in the load reversing device T1; the axes of the main clutch shaft S1 and the main transmission driving shaft S4 are on the same straight line, and the power output front shaft S5 passes through the inside of the main transmission drive shaft S4.

[0011] In the load reversing device T1, the reversing driving gear 1 is installed on the input shaft S1, and the forward clutch F and the reverse clutch R are fixedly installed. The reversing primary d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com