Pile driver

A technology of pile driver and hammer, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of easily damaged piston and cylinder seals, small hammer strike force, poor operation comfort, etc. The effect of increasing the strike strength and reducing the vibration sense

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and through the examples. The following examples are to explain the present invention and the present invention is not limited to the following examples.

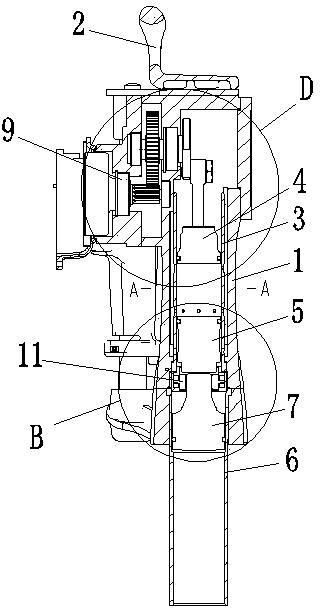

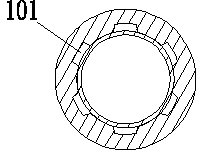

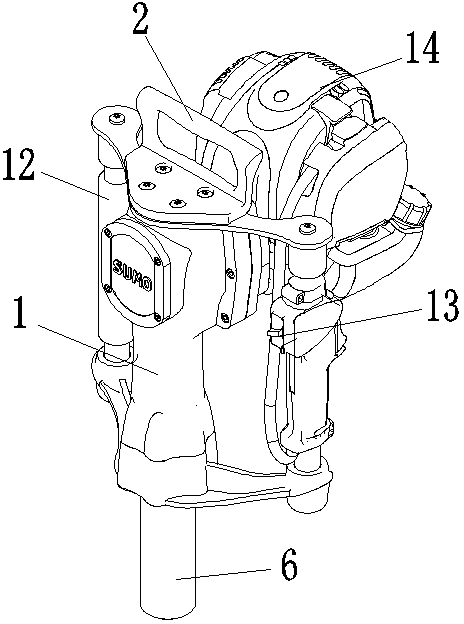

[0032] see Figure 1 to Figure 14 , the pile driver in this embodiment includes a box body 1, a handle 2, a cylinder 3, a piston 4, a hammer 5, a casing 6, an anvil 7, a connecting rod 8, a transmission device 9, a crankshaft 10, an anvil holder 11. The shock absorber 12, the accelerator switch 13, the power source 14, the sealing ring 15, the buffer ring 16 and the clutch housing 17.

[0033] In this embodiment, the handle 2 is fixed on the top of the box body 1, and the handle 2 is made of hard plastic material, with a smooth and smooth appearance, a reasonable design, and a comfortable grip. The hand 2 is made of hard plastic material, and the prior art is usually made of metal material, so it is ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com