Vehicle having a transmission and a selection element for shifting gears

A transmission and manual transmission technology, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve problems such as increasing manufacturing costs, achieve high operating comfort, small shifting force, and improve operating safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

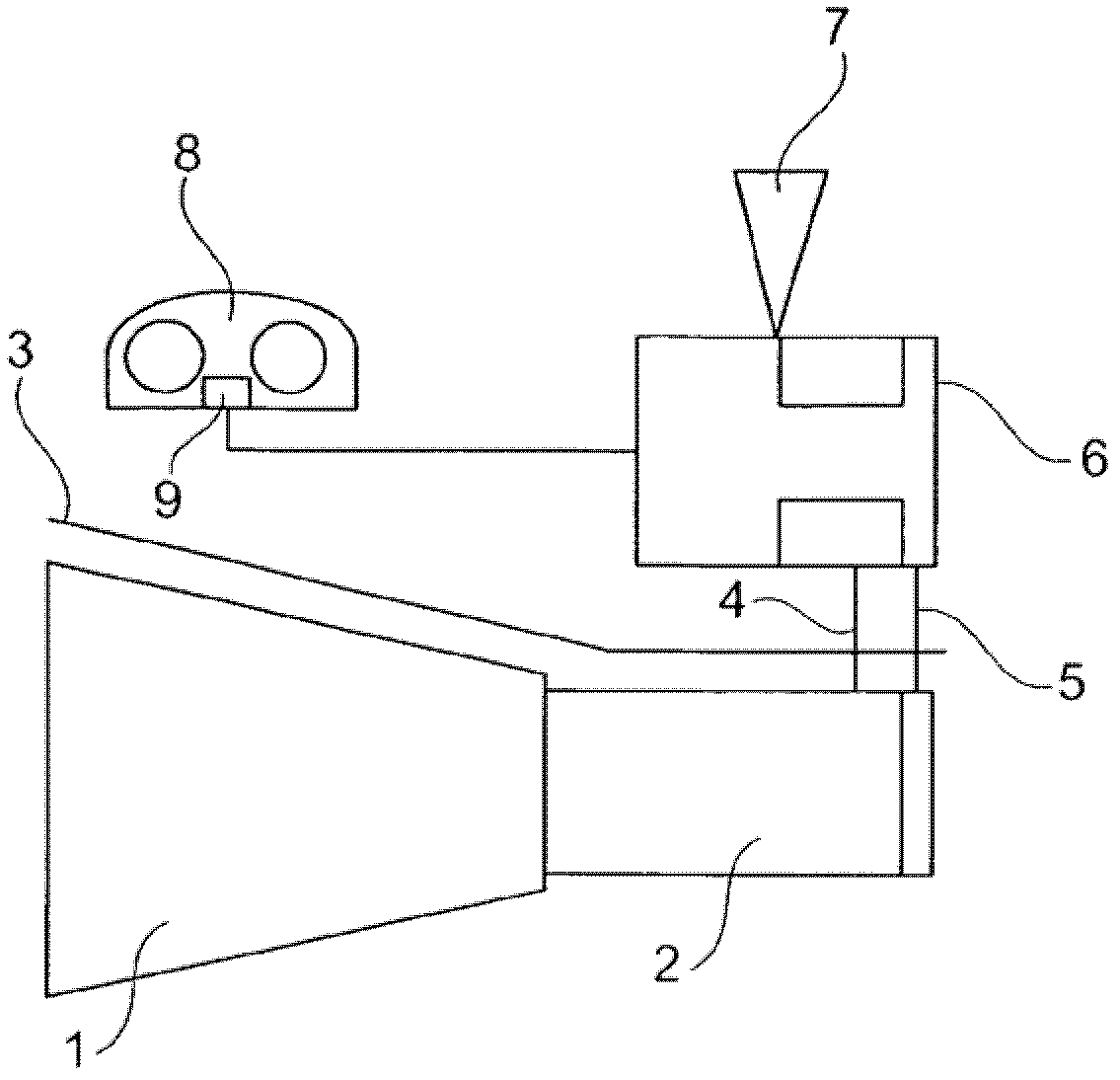

[0032] figure 1 A manual transmission 1 is shown with an actuator module 2 in which a plurality of electrically or electronically controllable actuators for engaging or disengaging transmission gears or gear stages are arranged. Also integrated in the actuator module 2 is a sensor system (not shown in detail here) which detects whether a specific gear is engaged or disengaged. The transmission 1 and the actuator module 2 are arranged in an intermediate sump, with respect to which the figure 1 In the cross-section shown in , only the bottom channel plate 3 can be seen.

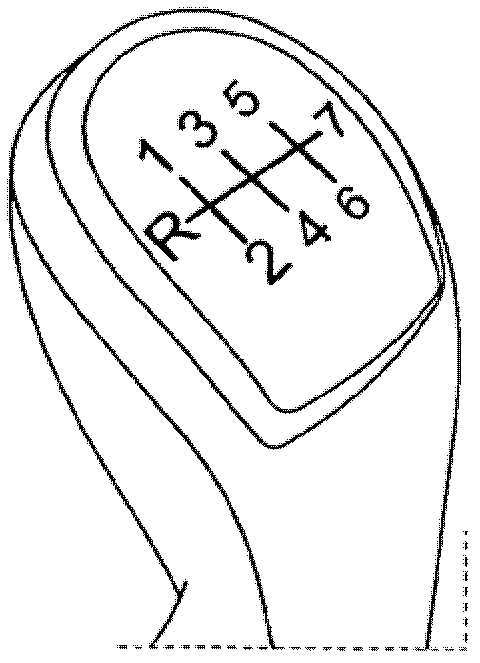

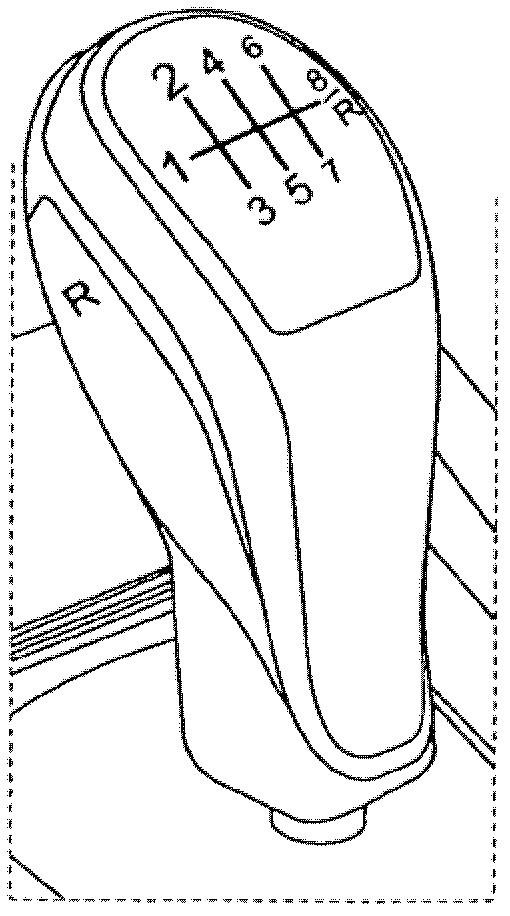

[0033] Actuator module 2 is connected via electrical lines 4 , 5 to an electromechanical element 6 which is arranged, for example, in a center console of a vehicle (not shown in detail here). A selection element 7 is arranged on the upper side of the electromechanical element 6 . The selection element 7 is arranged, for example, pivotably and / or displaceably and / or rotatably or otherwise movably on the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com