Agricultural vehicle gearbox with wet type clutch

A wet clutch and gearbox technology, applied in the gearbox field, can solve the problem of no sealed oil groove, etc., and achieve the effects of strong transmission torque, reduction of processing costs, and improvement of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

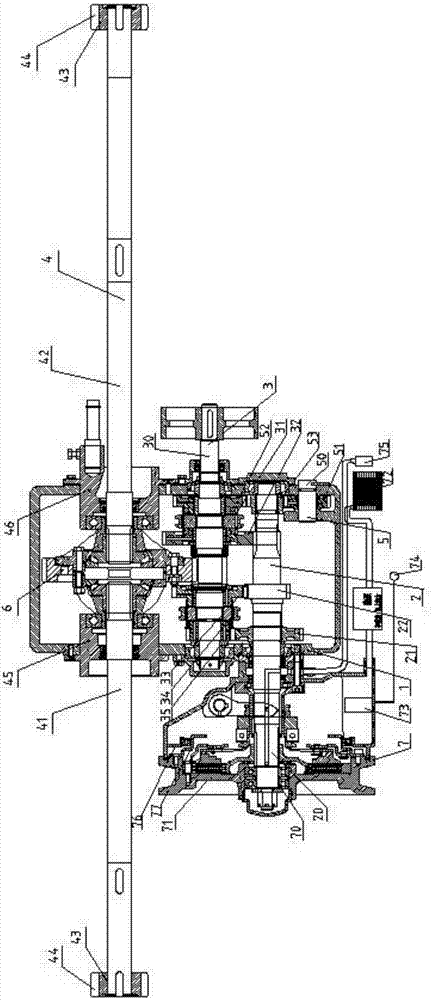

[0024] The main structure of the agricultural vehicle gearbox with wet clutch involved in this embodiment includes a gearbox housing 1 with a gearbox upper cover installed on the top, a shaft assembly 2 installed in the gearbox housing 1, an intermediate shaft assembly 3, the output shaft assembly 4, the reverse gear idler shaft assembly 5 and the differential assembly 6, and the wet clutch assembly 7 installed outside the gearbox housing 1, and the middle part of the inner cavity of the gearbox housing 1 is horizontally arranged There is an intermediate shaft assembly 3, an output shaft assembly 4 is arranged horizontally above the intermediate shaft assembly 3, a differential assembly 6 is arranged above the output shaft assembly 4, and a shaft assembly is arranged horizontally below the intermediate shaft assembly 3 Into 2, a reverse gear id...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com