Gear shifting servo system

A technology of servo system and servo valve, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc. It can solve the problems of unfavorable light weight, large overall frame, large structural shape, etc., and achieve fast shifting of the system Smooth and accurate, improved gear shifting experience, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

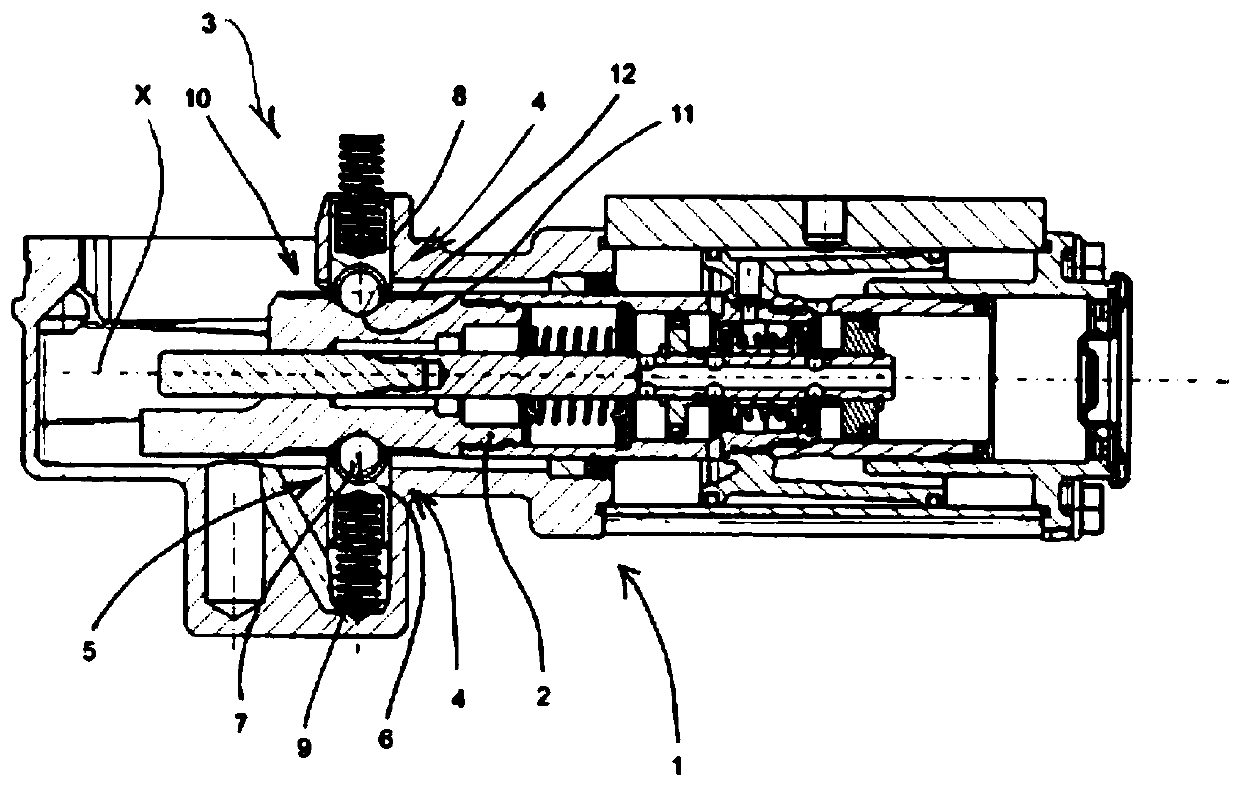

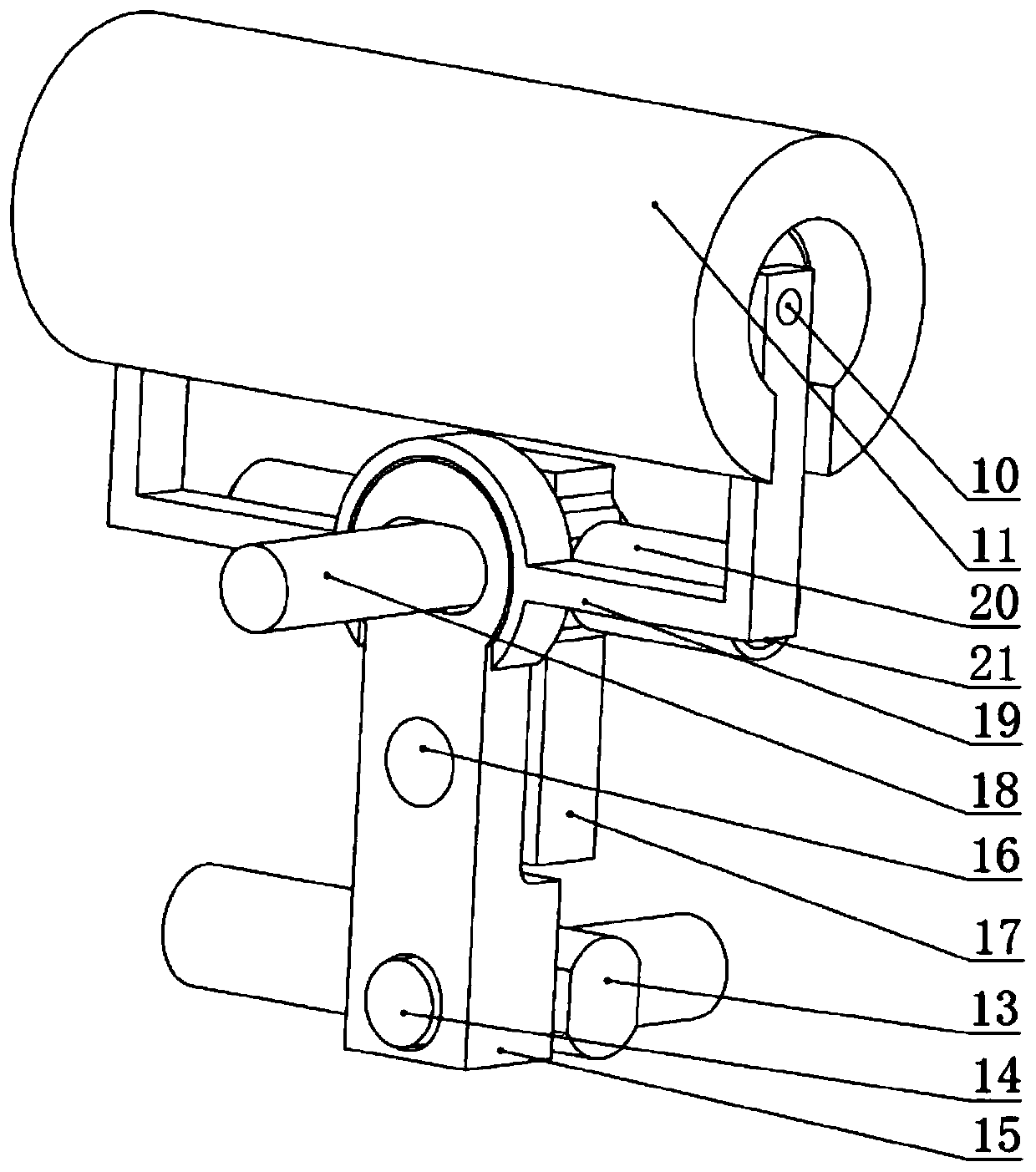

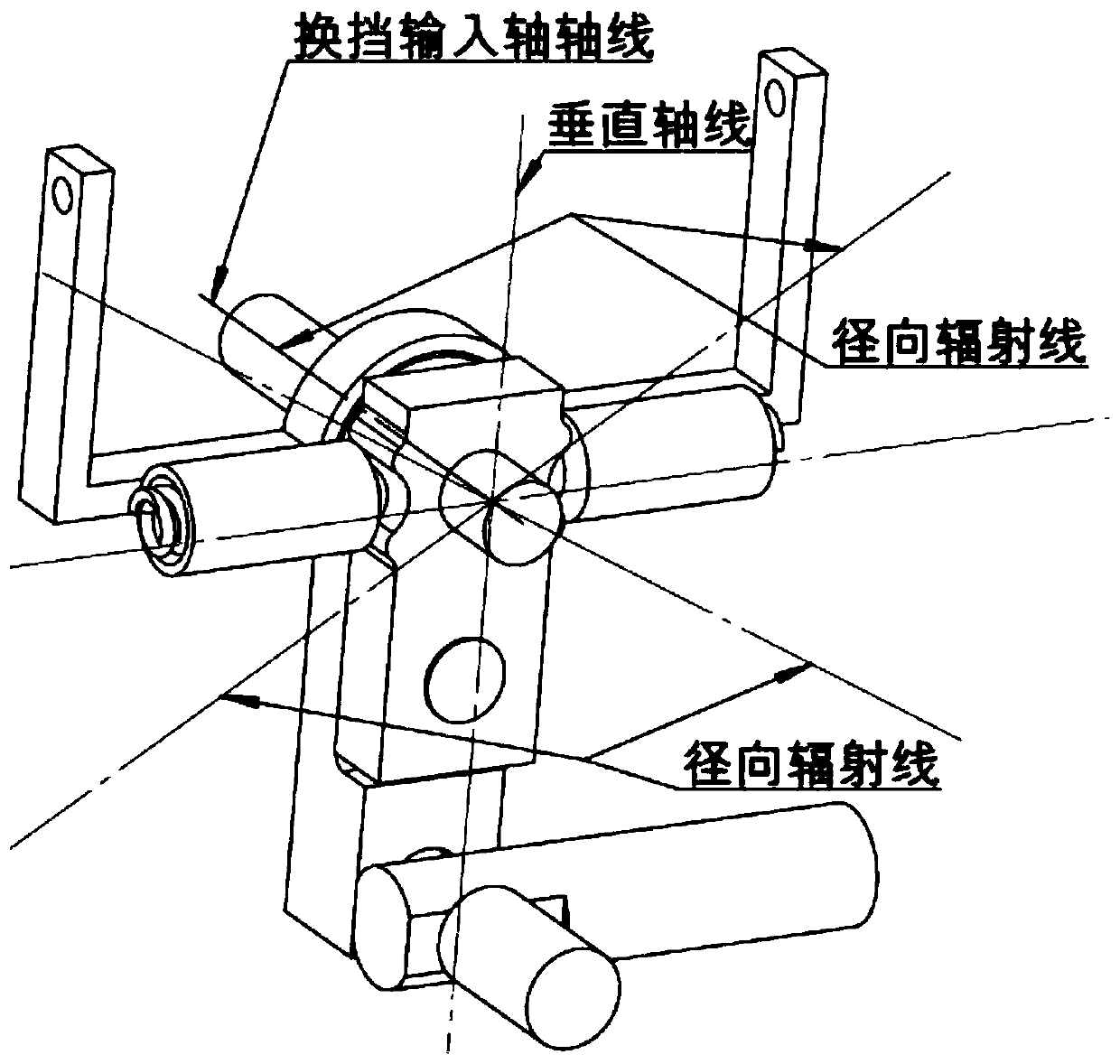

[0030] see figure 2 , in one of the embodiments, a shifting servo system, including a shifting input shaft 18, a transmission mechanism, a deflection mechanism, a servo valve structure, a shifting actuator and a positioning mechanism, the transmission mechanism and the shifting input The shaft 18 is connected to convert the shifting action of the shifter into radial rotation; the deflection mechanism, the deflection mechanism includes a passive element 17, a deflection element 15 and a deflection actuator 19, wherein the passive element and the deflection actuator The yaw element is rotatably connected by a pin shaft 16, the axis of the pin shaft 16 is spaced from and parallel to the axis of the shift input shaft 18, and a connecting portion is provided at one end of the yaw element, and the connecting portion accommodates The circular arc ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com