Shifting device of a motor vehicle speed-change gearbox

A technology of motor vehicle transmission and shifting device, which is applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve problems such as cost, and achieve the effect of simple structure and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

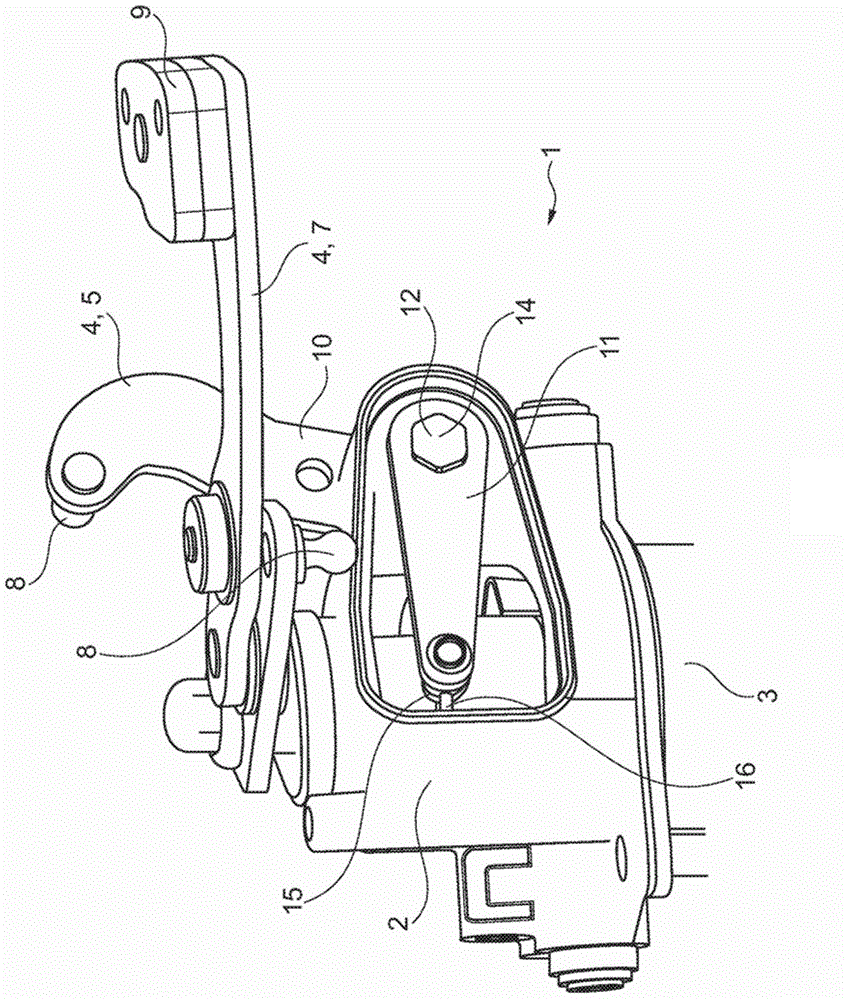

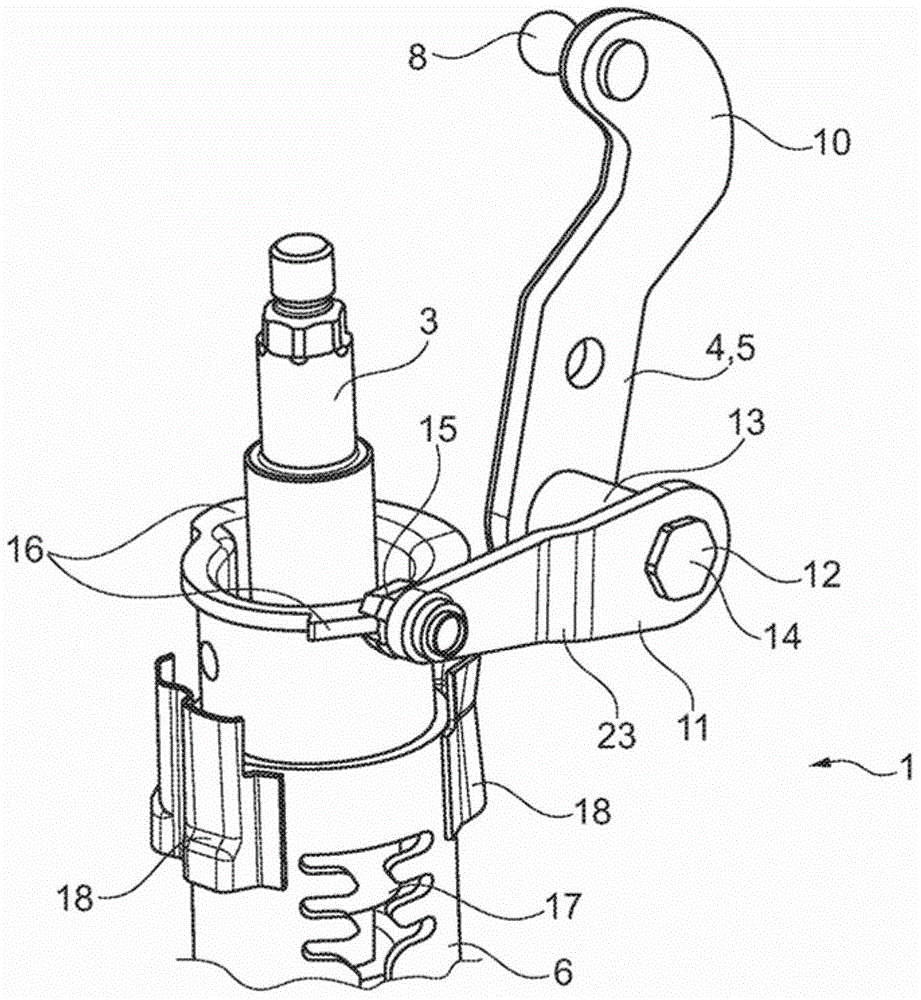

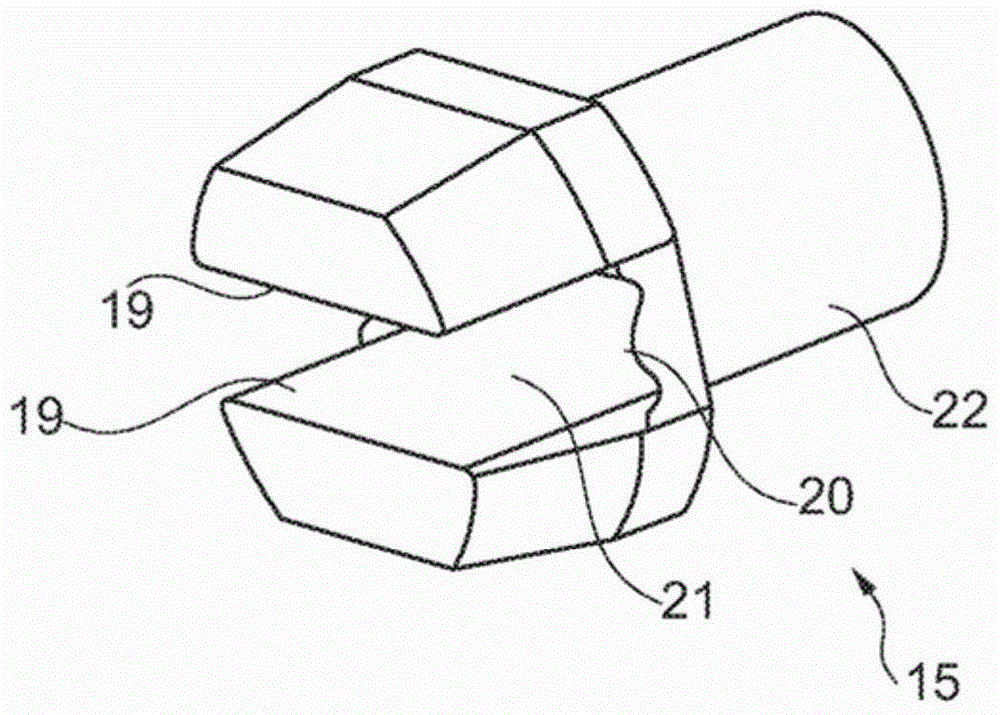

[0027] figure 1 with 2 The shift device 1 in the form of a shift mechanism box frame is shown. The shift mechanism box frame includes: a housing 2 that can be screwed to the transmission housing with an unshown housing part; a shift lever 3 configured as a shift shaft and rotatably supported in the housing 2; And two handles 4 for moving the shift lever 3.

[0028] The handle 4 is respectively constituted as a shift lever 5 and a shift lever 7, wherein by means of the shift lever, the sleeve 6 connected to the shift lever 3 in a non-rotatable manner can move in a translational manner. The handle causes the sleeve 6 to rotate. The shanks 4 are each constructed in multiple parts and each have a ball head 8 for their articulation via a cable drive. The rope transmission device is connected with the shift handle of the operator.

[0029] The shift lever 7 is provided with a shift block 9 on its radially outer end, which increases the moment of inertia of the shift device 1 in order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com