Automatic transmission mechanical parking mechanism

A technology of automatic transmission and parking mechanism, which is applied in the direction of mechanical equipment, transmission device control, and components with teeth, etc., which can solve the problem of difficult position guarantee, difficult control of parking brake spring leaf bending angle, and spring leaf spring Problems such as fast force value attenuation, etc., achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Referring to the accompanying drawings, specific embodiments of the present invention will be described in detail.

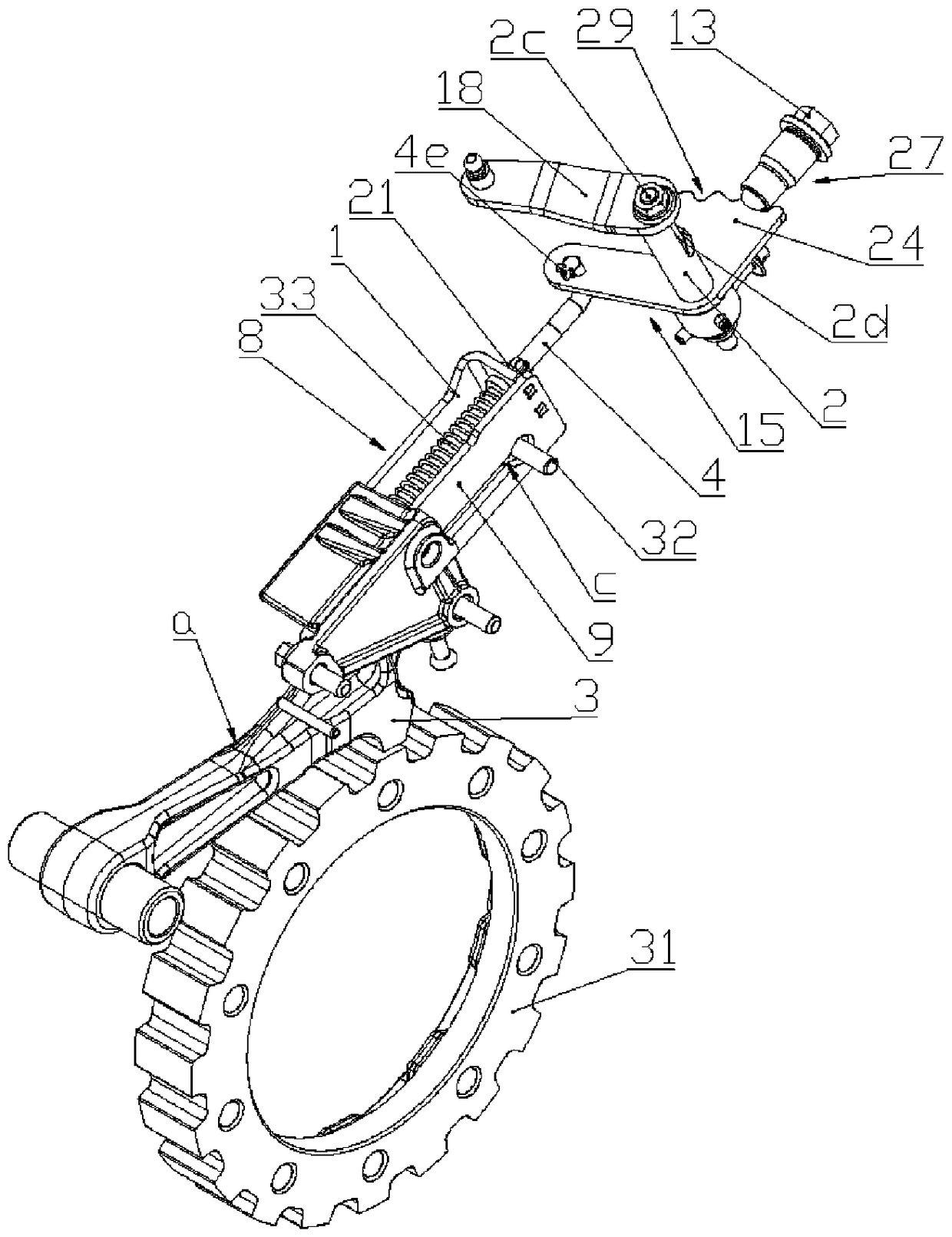

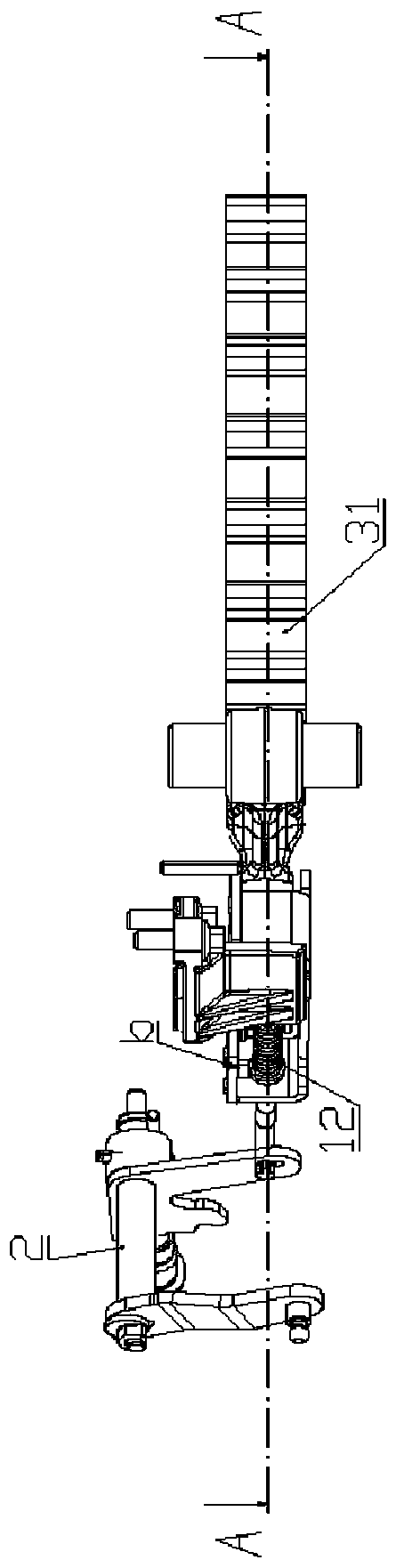

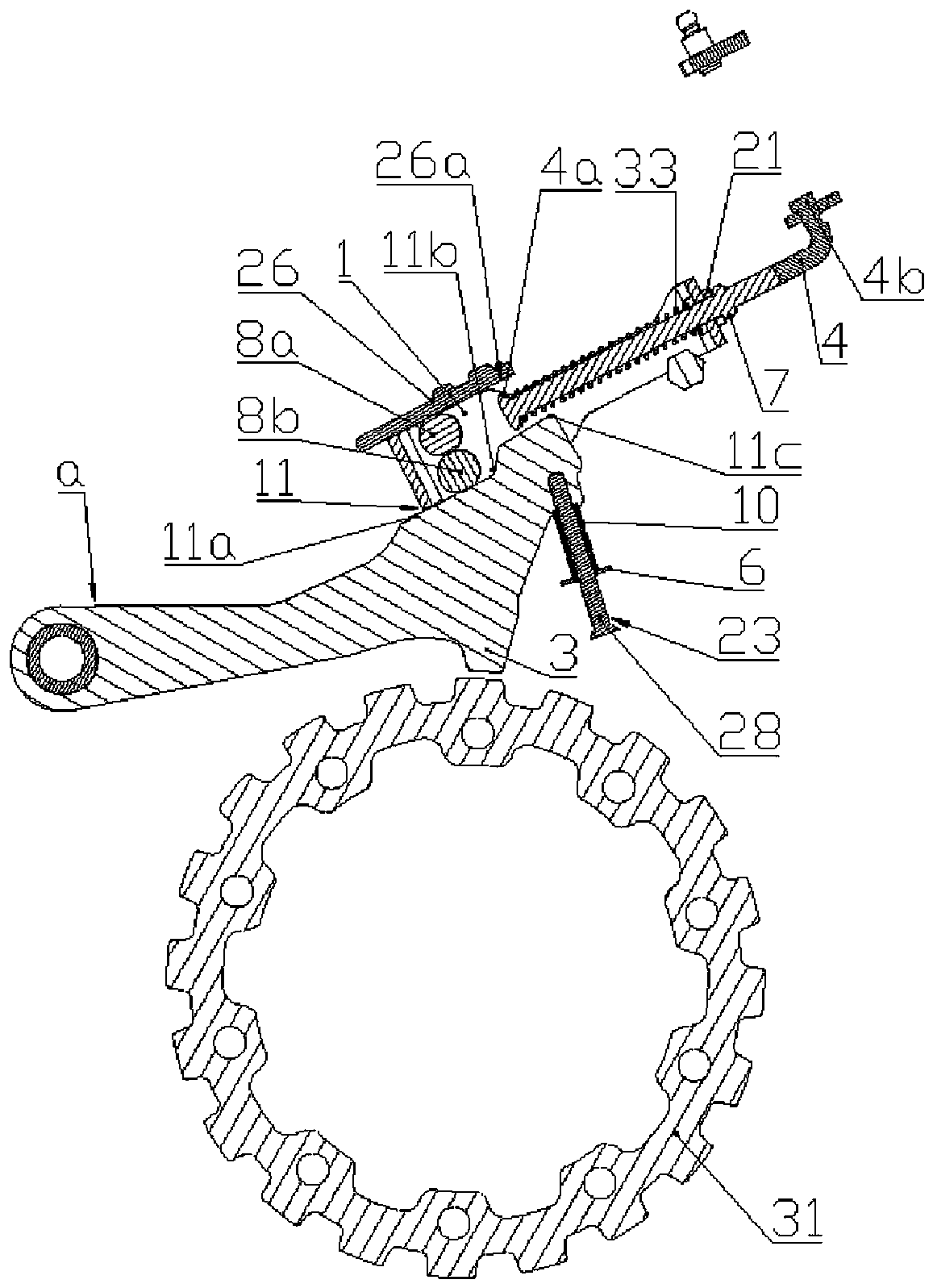

[0033] see Figure 1 to Figure 5 , an embodiment of the mechanical parking mechanism of the automatic transmission, the mechanical parking mechanism of the automatic transmission includes a parking ratchet 31 circumferentially fixed on the transmission shaft system, and a parking pawl hinged on the transmission case 30 a, the mechanical parking mechanism of an automatic transmission, including a parking ratchet 31 circumferentially fixed on the transmission shaft, and a parking pawl a hinged on the transmission case 30 . Preferably, the parking ratchet 31 is circumferentially fixed on the differential rotating housing 34 in the transmission shaft system, and the parking ratchet 31 is installed on the differential housing, which solves the problem that the parking ratchet 31 is installed on the input shaft. , Under severe working conditions, the input sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com