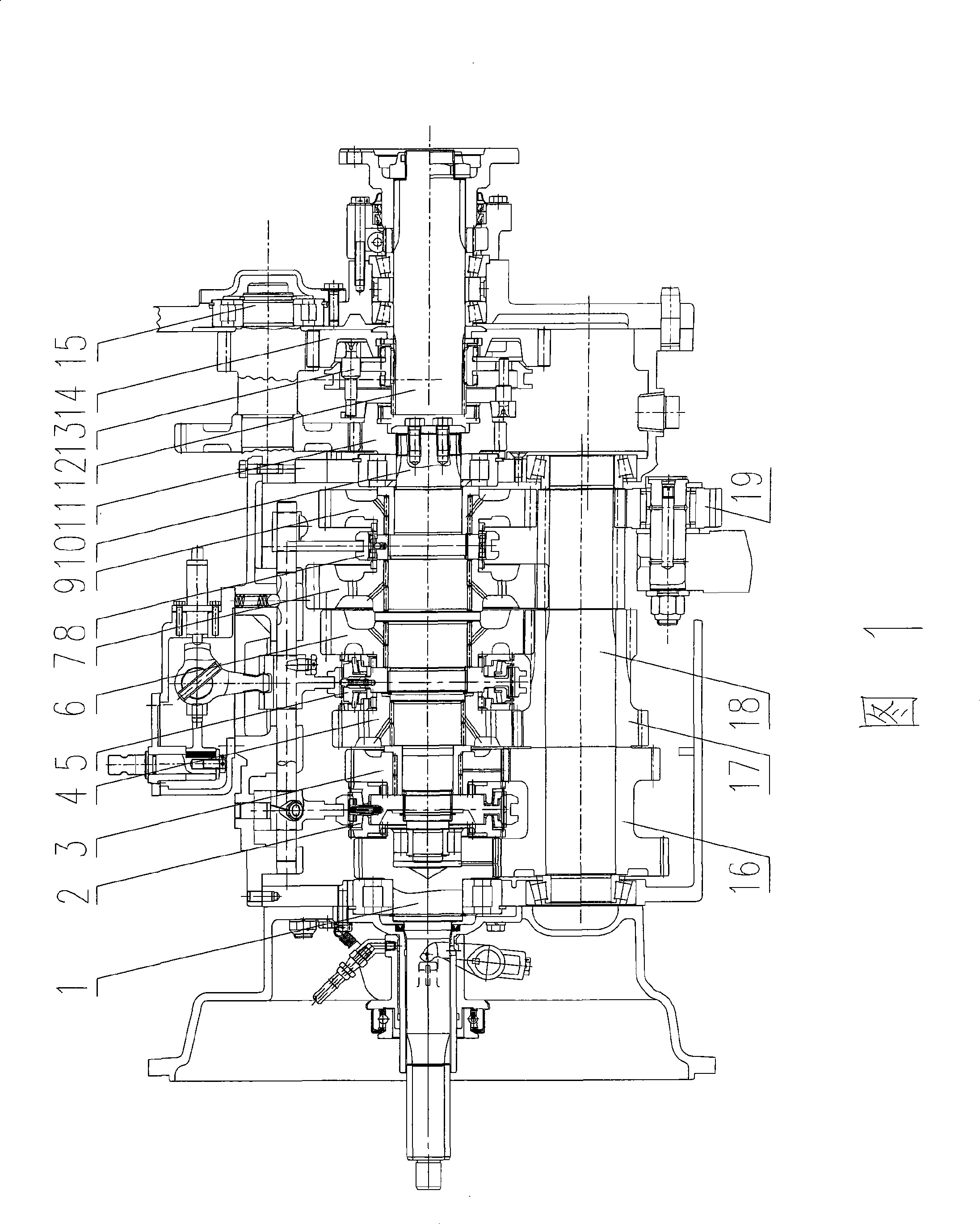

Automobile speed variator with main-sub case sub shaft of antisymmetric arrangement

An automobile transmission, asymmetric technology, applied in the direction of transmission box, transmission, transmission parts, etc., can solve the problems of not well matched, no advantage in bearing capacity, great influence on the life of the synchronizer, etc., to achieve convenient operation, The effect of reducing driving intensity and small shifting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

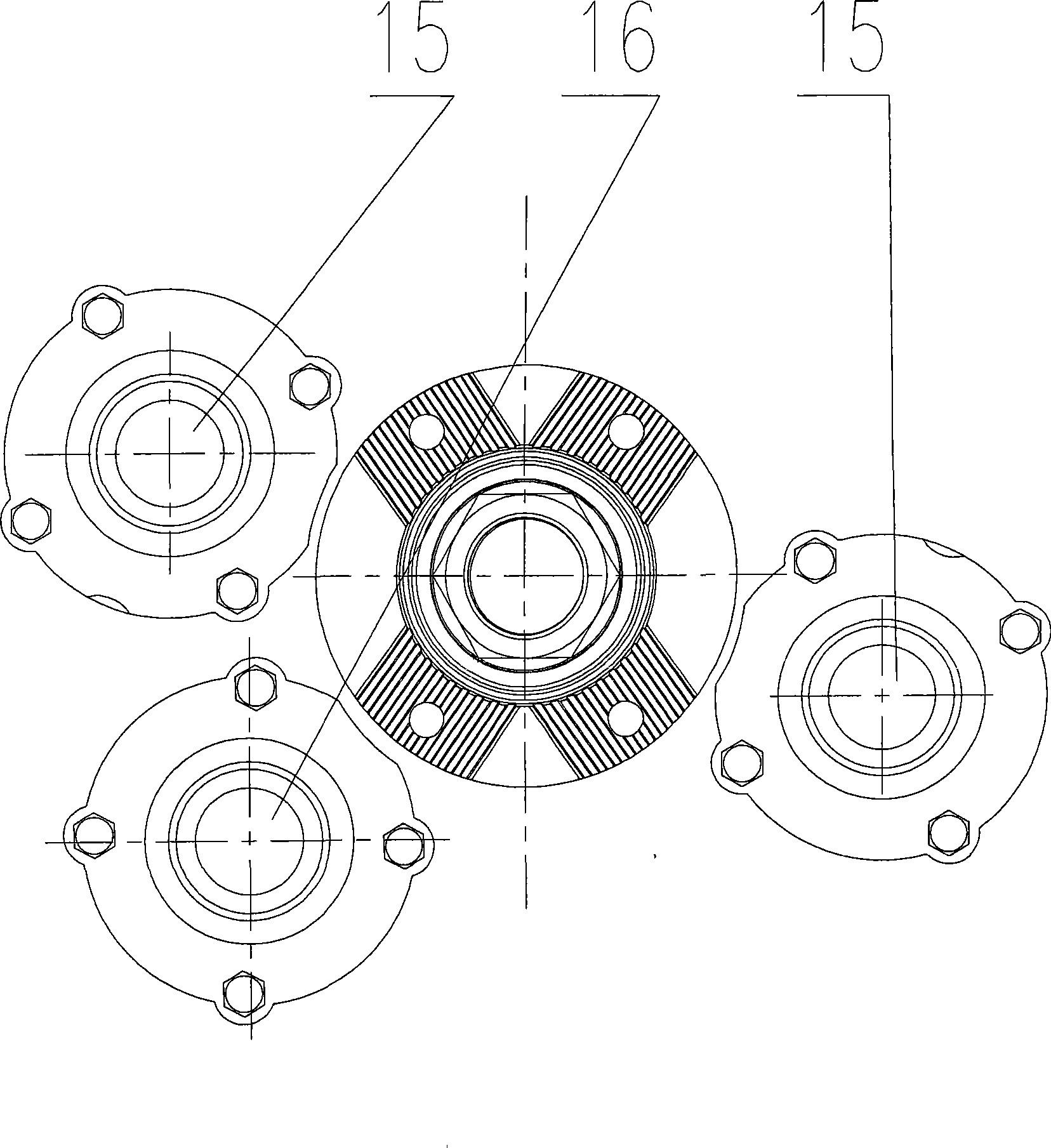

[0010] As shown in Figure 1, an automobile transmission with an asymmetric arrangement of main and auxiliary boxes and auxiliary shafts is composed of a main box and an auxiliary box. The main box of the transmission is equipped with a shaft 1 and a second shaft 10, and a main shaft 10 is arranged on one side of the second shaft 10 Case subshaft 18, the gear on the first shaft is meshed with countershaft gear 16, and gear 3,4,6,7,9 is mounted on the two shafts, and the conjoined two gears 19 meshes on the countershaft gear 16,17, the countershaft. The gear on the two shafts and the two shafts are empty sleeves, axially positioned, and can idle around the two shafts, and the two shafts are equipped with a synchronizer and a gear sleeve to rotate together with the two shafts. The gears on the countershaft rotate with the countershaft fixed. The synchronizer 8 is installed between the gear 7 and the gear 9, the synchronizer 5 is installed between the gear 4 and the gear 6, the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com