A transmission for plant protection machinery

A transmission and transmission housing technology, which is applied in mechanical equipment, vehicle transmissions, gear transmissions, etc., can solve the problems of gear arrangement not conforming to work habits, inconvenient operation by staff, and inability to meet usage requirements, etc. The gear arrangement is clear and reasonable, the effect of avoiding disengagement and random gearing, and reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

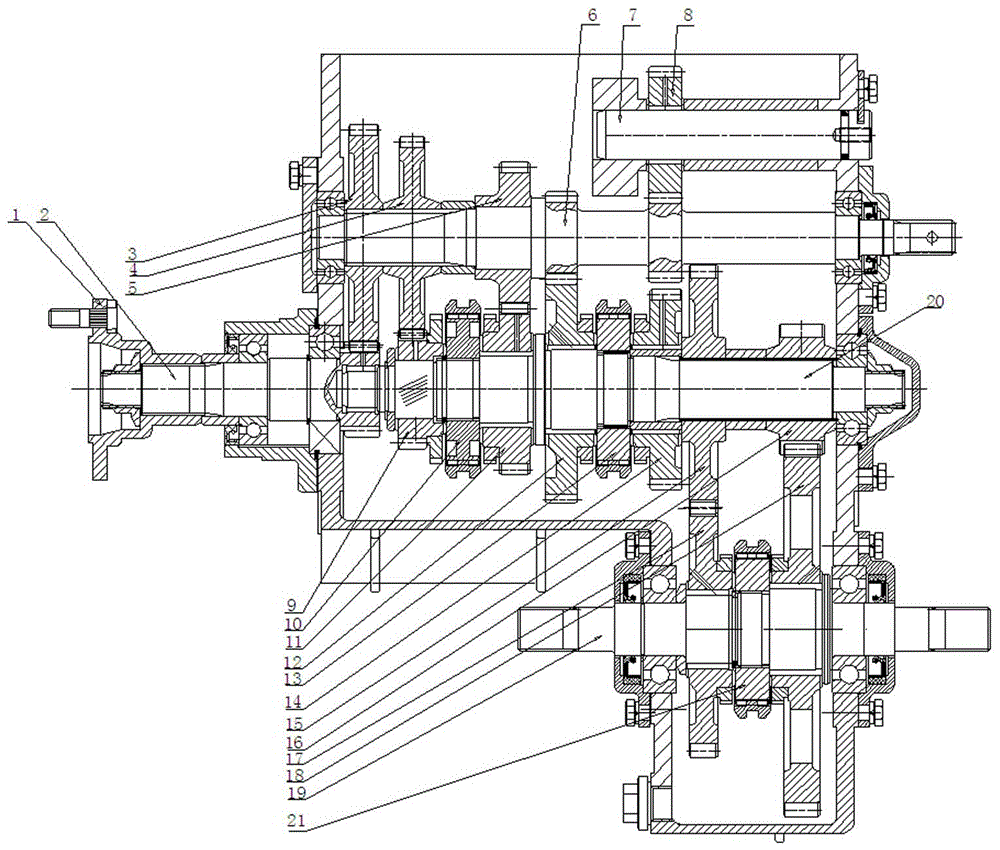

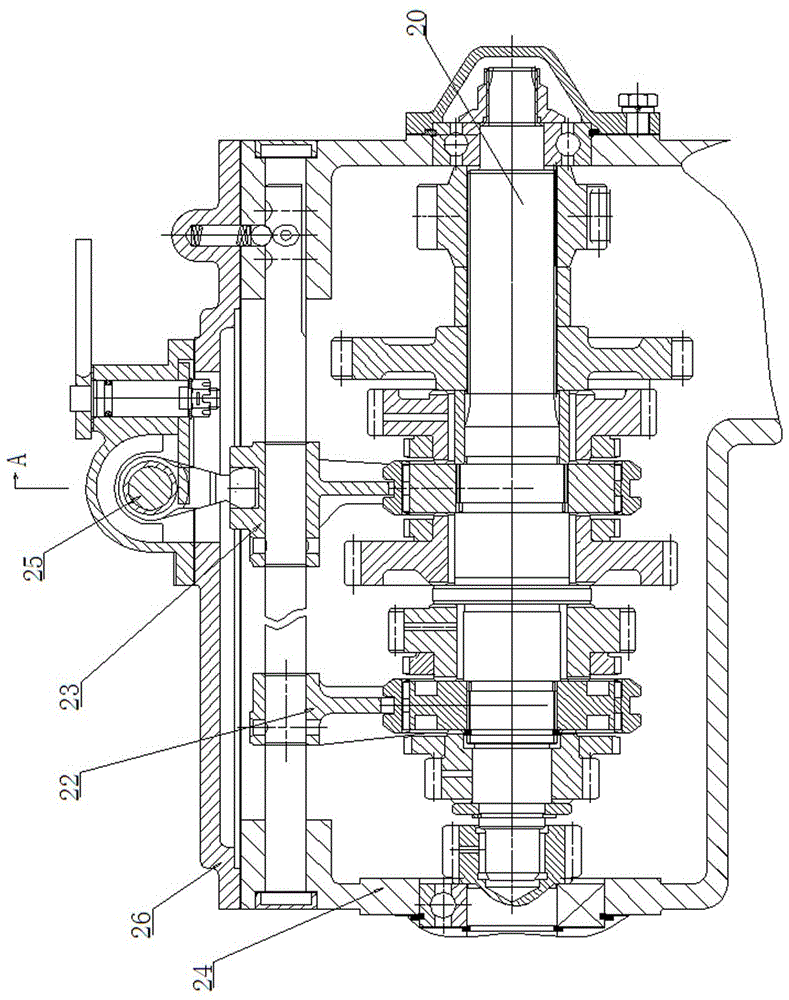

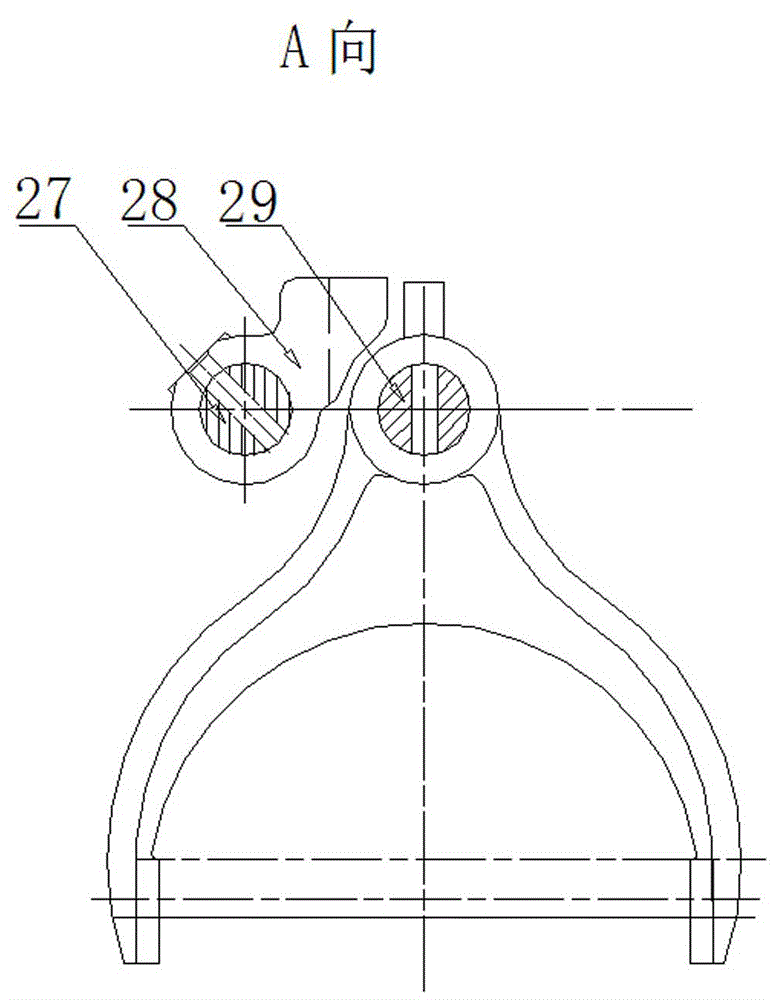

[0047]The speed changer for plant protection machinery includes a speed change case 24 with a loam cake 26 installed on the top, and one shaft 2, two shafts 6, three shafts 20, reverse gear idler shaft 7 and output shaft 19 installed in the speed change case 24, one Shaft 2 is a gear shaft, its outer end is connected to input flange 1, and input flange 1 is connected to engine clutch assembly through transmission shaft 45. Engine clutch assembly includes: clutch housing 38, clutch shaft 39, clutch dial shaft 41 and clutch Output flange 40, clutch shaft 39 is installed in the body of clutch case 38 by clutch sleeve seat 37, the output end of clutch shaft 39 is connected with transmission shaft 45 by clutch output flange 40, and one end of clutch shaft 39 in clutch case 38 body is from the left Connecting disc 34, clutch driven disc 35 and clutch driving disc 36 are installed to the right, and release bearing 43 and release bearing seat 44 are installed outside the clutch cover s...

Embodiment 2

[0066] The speed changer for plant protection machinery includes a speed change case 24 with a loam cake 26 installed on the top, and one shaft 2, two shafts 6, three shafts 20, reverse gear idler shaft 7 and output shaft 19 installed in the speed change case 24, one Shaft 2 is a gear shaft, its outer end is connected to input flange 1, and input flange 1 is connected to engine clutch assembly through transmission shaft 45. Engine clutch assembly includes: clutch housing 38, clutch shaft 39, clutch dial shaft 41 and clutch Output flange 40, clutch shaft 39 is installed in the body of clutch case 38 by clutch sleeve seat 37, the output end of clutch shaft 39 is connected with transmission shaft 45 by clutch output flange 40, and one end of clutch shaft 39 in clutch case 38 body is from the left Connecting disc 34, clutch driven disc 35 and clutch driving disc 36 are installed to the right, and release bearing 43 and release bearing seat 44 are installed outside the clutch cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com