HST hydraulic mechanical variable-speed drive axle for agricultural harvesting machine

A technology of harvesting machinery and hydraulic machinery, applied in agricultural machinery and implements, agriculture, harvesters, etc., can solve problems such as weak walking, frequent replacement of clutch assemblies, difficulty in gearing gears, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to more clearly and clearly illustrate the specific implementation objectives and implementation modes of the present invention, the technical solution of the present invention will be fully described below, and the described embodiments are part of the embodiments of the present invention, rather than all embodiments. On the premise of no creative work, all other embodiments based on the described embodiments of the present invention belong to the protection scope of the present invention.

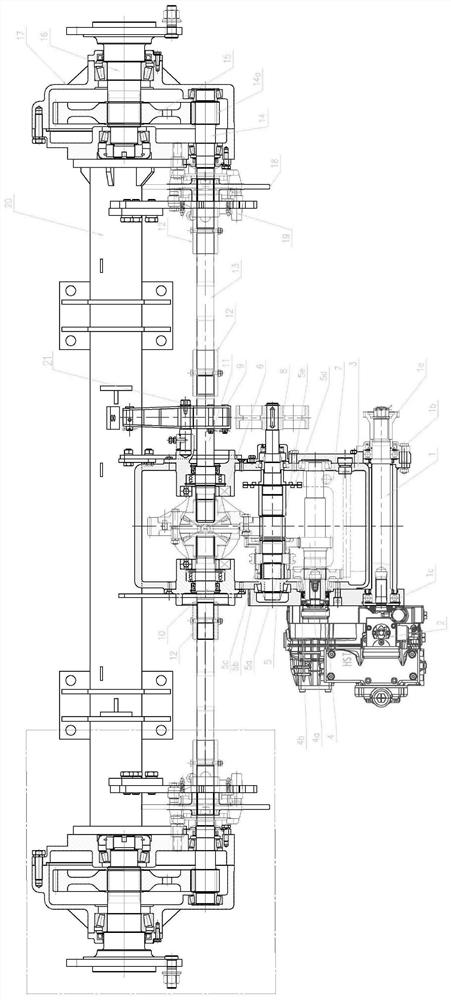

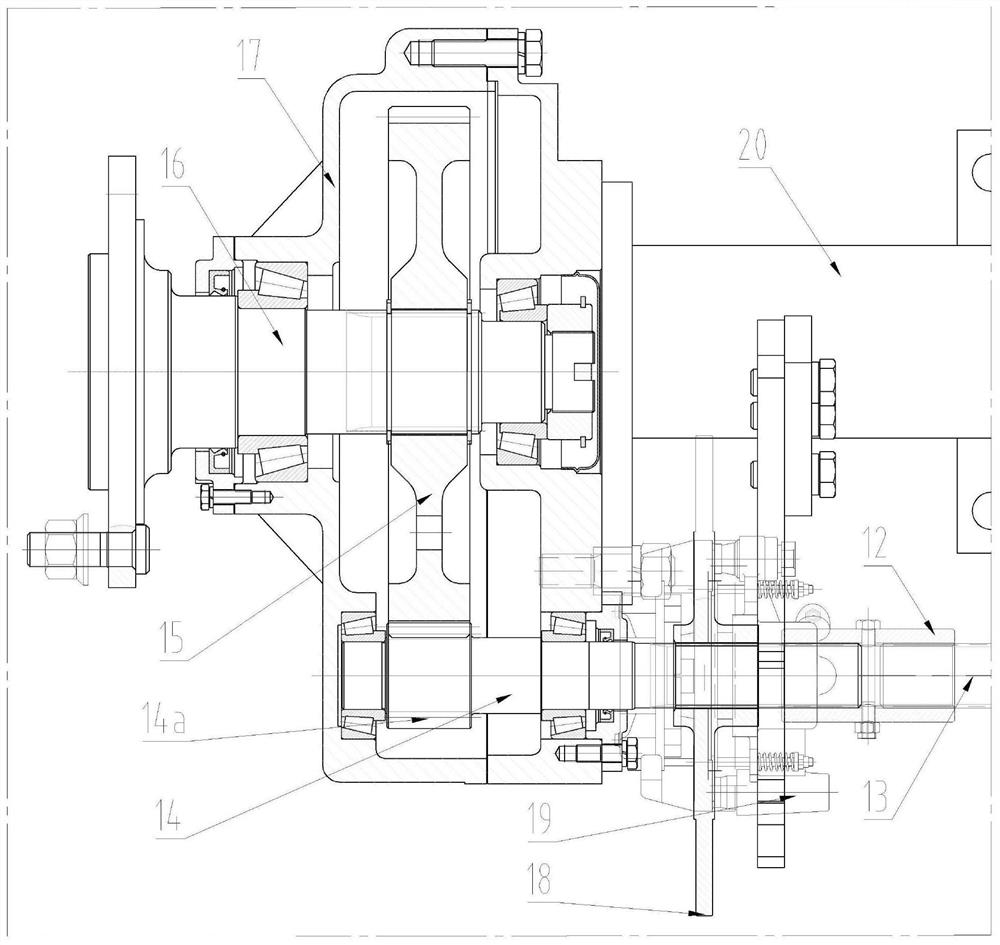

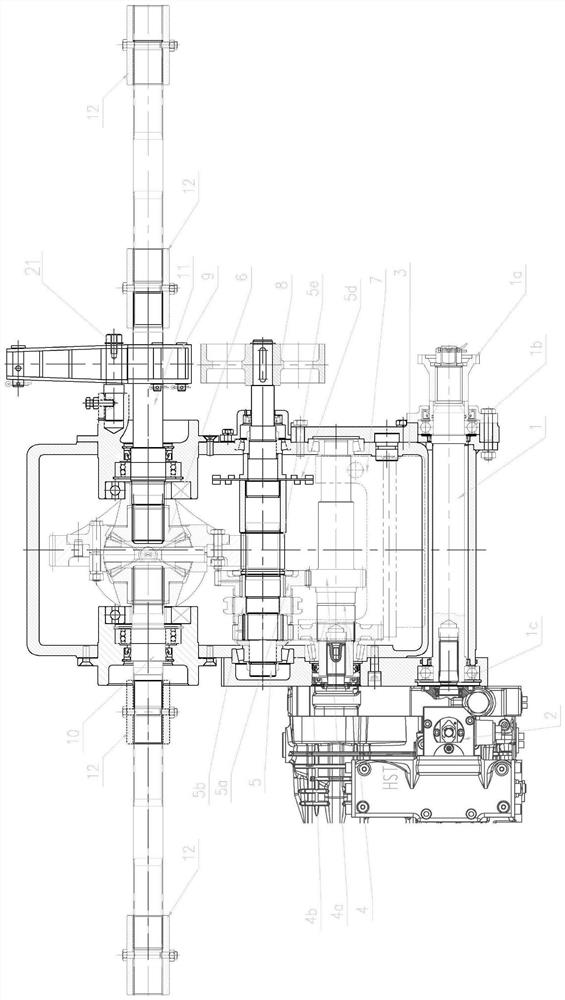

[0038] A kind of HST hydraulic mechanical transaxle for agricultural harvesting machinery of the present invention, such as figure 1 shown, including:

[0039] The gearbox 3 and the bridge welded beam 20 fixedly connected to each other, such as figure 1 , figure 2 As shown, a differential assembly 6 is installed inside the gearbox 3 , and a left half shaft 10 and a right half shaft 11 are coaxially arranged on both sides of the differential assembly 6 . The ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com