Transmissions for Motor Vehicles

A technology for transmissions and motor vehicles, which is applied in the direction of vehicle gearboxes, transmissions, mechanical equipment, etc. It can solve the problems of high component load of clutches and short residence time of sub-transmissions, and achieve the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

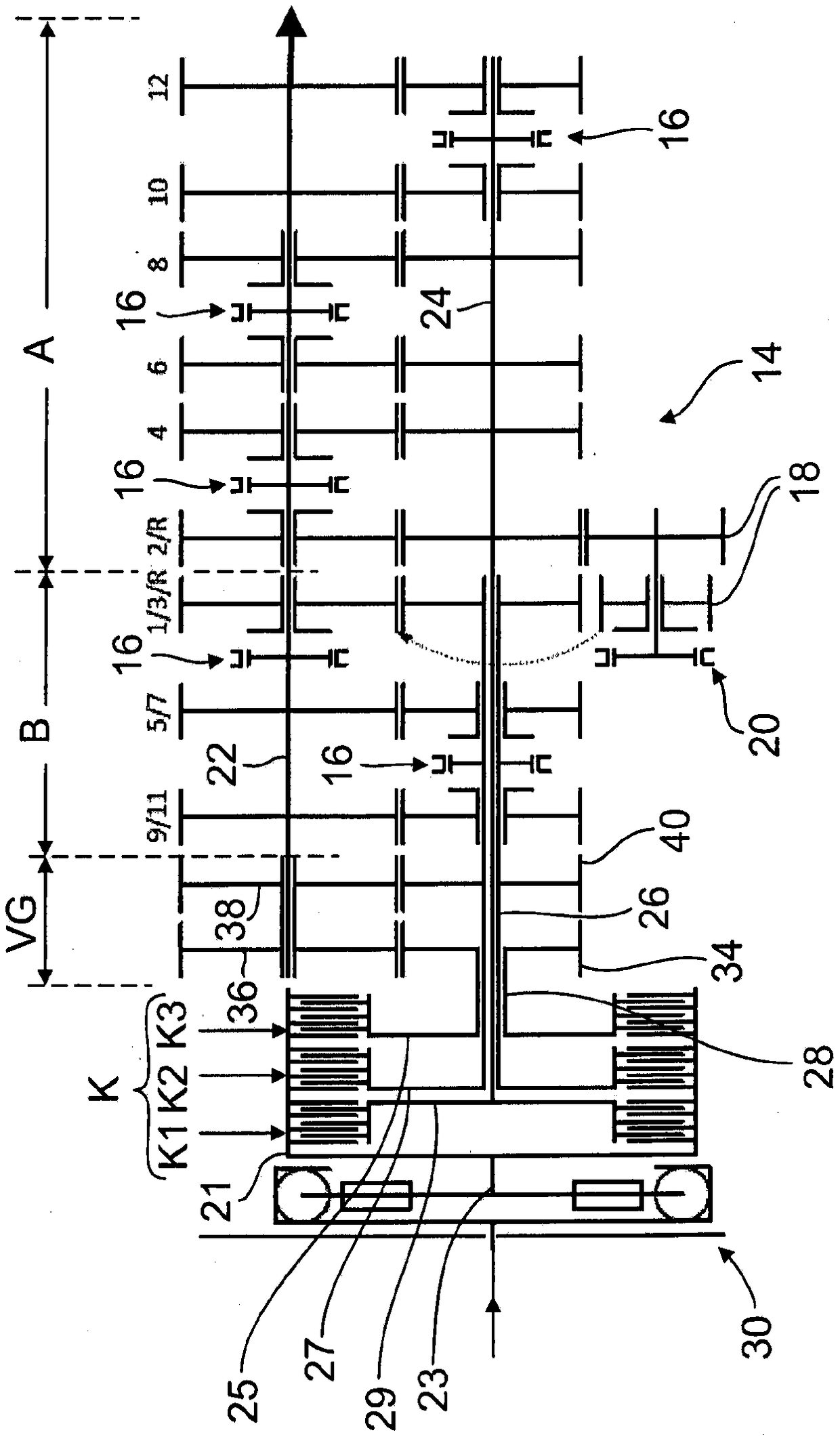

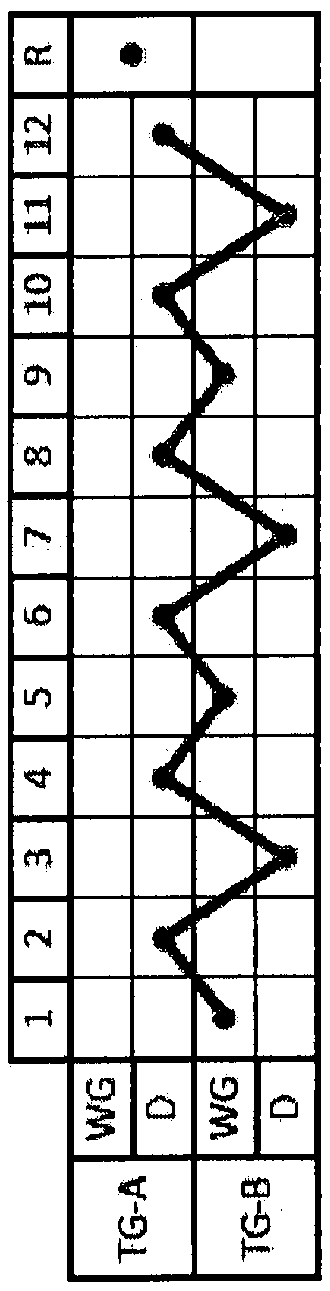

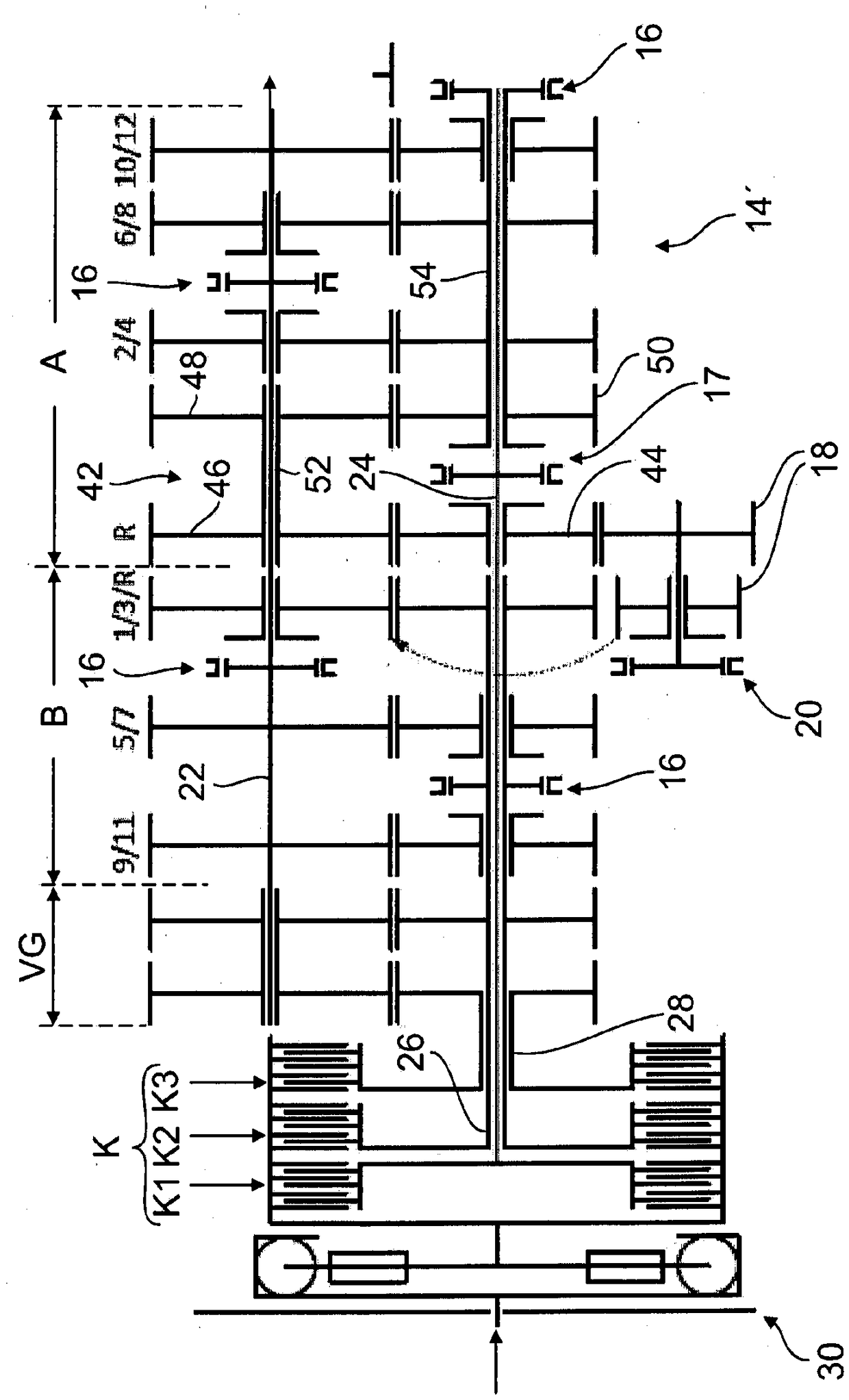

[0031] exist figure 1 shows a block diagram of a transmission 14 for a motor vehicle, which in the exemplary embodiment has twelve forward gears 1 to 12 and a total of three reverse gears R, which are formed by gear sets meshing with each other, wherein the gear sets can The shifting takes place in a manner known per se via shifting or synchronous clutches (identified collectively with 16 ) on the floating gear.

[0032]The gear set with fixed gears and switchable floating gears is divided into two sub-transmissions A and B, where sub-transmission B corresponds to the odd numbered forward gears (from left to right in the drawing) 9 / 11, 5 / 7 and 1 / 3 , and the even-numbered gears 2, 4, 6, 8, 10, and 12 can be switched through corresponding multiple gear sets via the sub-transmission A.

[0033] anyway in figure 1 The clutches K1, K2 and K3 can be used to switch the three reverse gears R. The reverse gear R, which differs in transmission ratio, can be shifted by means of the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com