Transmission shifting mechanism for all-electric cars

A pure electric car, shifting mechanism technology, applied in the direction of transmission control, mechanical equipment, components with teeth, etc., can solve the problems of long shifting time, large shifting force, increased vehicle ownership, etc. Quality and reliability, short shifting time, small shifting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

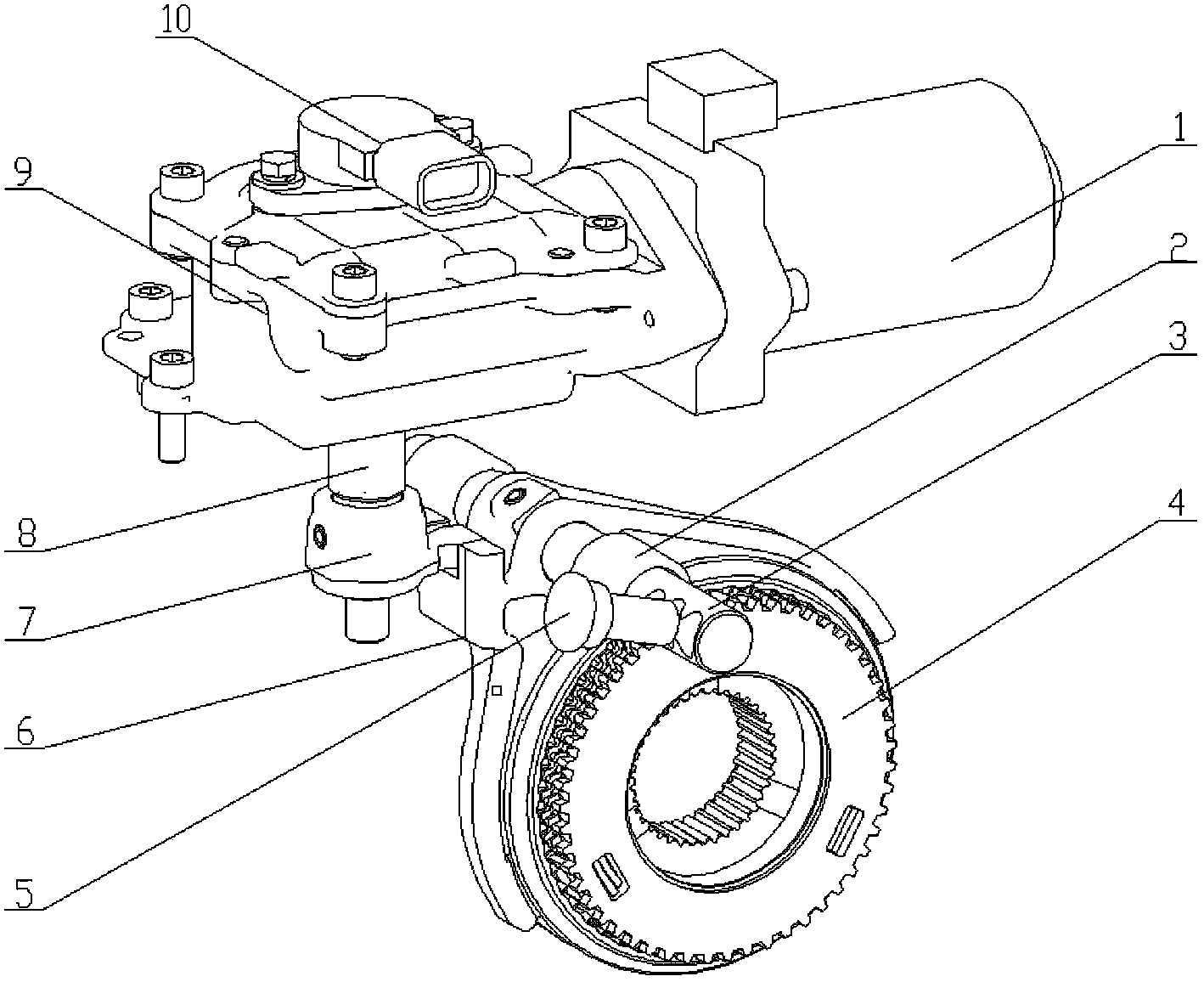

[0007] As shown in the drawings, the present invention includes a shift motor 1, a linear bearing 2, a shift fork shaft 3, a three-cone synchronizer 4, a self-locking pin 5, a shift fork 6, a shift dial 7, a shift shaft 8, a buffer 9, angle sensor 10, etc., the buffer 9 is connected with the shift motor 1, the shift shaft 8 is installed on the buffer 9 through a spline connection, and the two ends of the shift shaft 8 are respectively the angle sensor 10 and the shift dial 7 , there is an oil seal between the angle sensor 10 and the shift pad 7, the shift pad 7 is inserted into the hole of the shift fork 6, the shift fork 6 and the shift fork shaft 3 are connected together by pins, and the shift fork shaft 3 is connected by a linear bearing 2 is connected on the front and rear shells, and the shift fork 6 is inserted in the 4th ring gear of the three-cone synchronizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com