Single cone bit based on non-planar combination PDC strengthened teeth

A technology of strengthening teeth and non-planar surface, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of wear and short life, and achieve the effect of strong wear resistance, improved service life, and improved rock breaking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

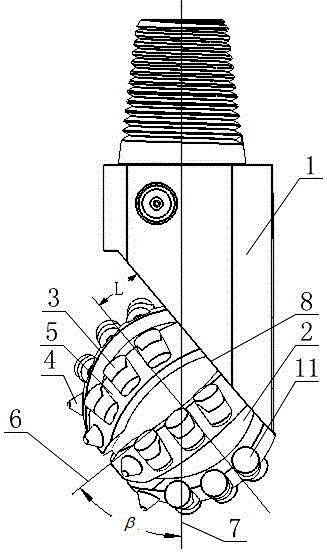

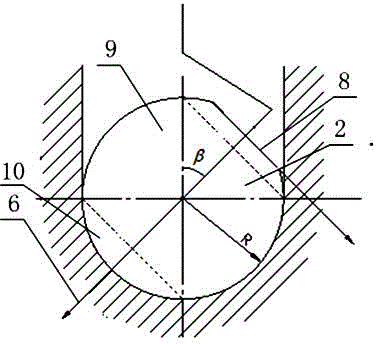

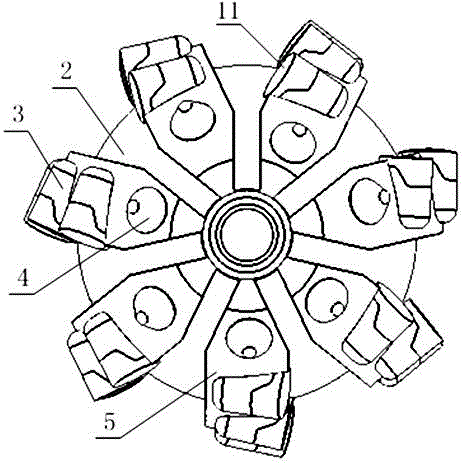

[0020] Such as figure 1 As shown, a single-cone bit based on non-planar combined PDC reinforced teeth, it includes a bit body 1 and a cone 2, the tooth surface of the cone 2 is a spherical surface with a radius R, the axis 6 of the cone and the bit body There is an included angle β between the axes 7. In this embodiment, the included angle β is 50°. The cone 2 has a cone end face 8 that matches the drill body 1. The distance from the center of the cone 2 to the cone end face 8 is L. In the present embodiment, L is 27.5 mm, and the vertical distance from any point on the tooth surface of the cone 2 to the end face 8 of the cone is h m , there are at least five toothed belts 5 vertically arranged on the toothed surface of the toothed wheel 2, and the toothed belts 5 are spiral or straight. In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com