Single cone vacuum drier

A single-cone vacuum drying and steam technology used in the field of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

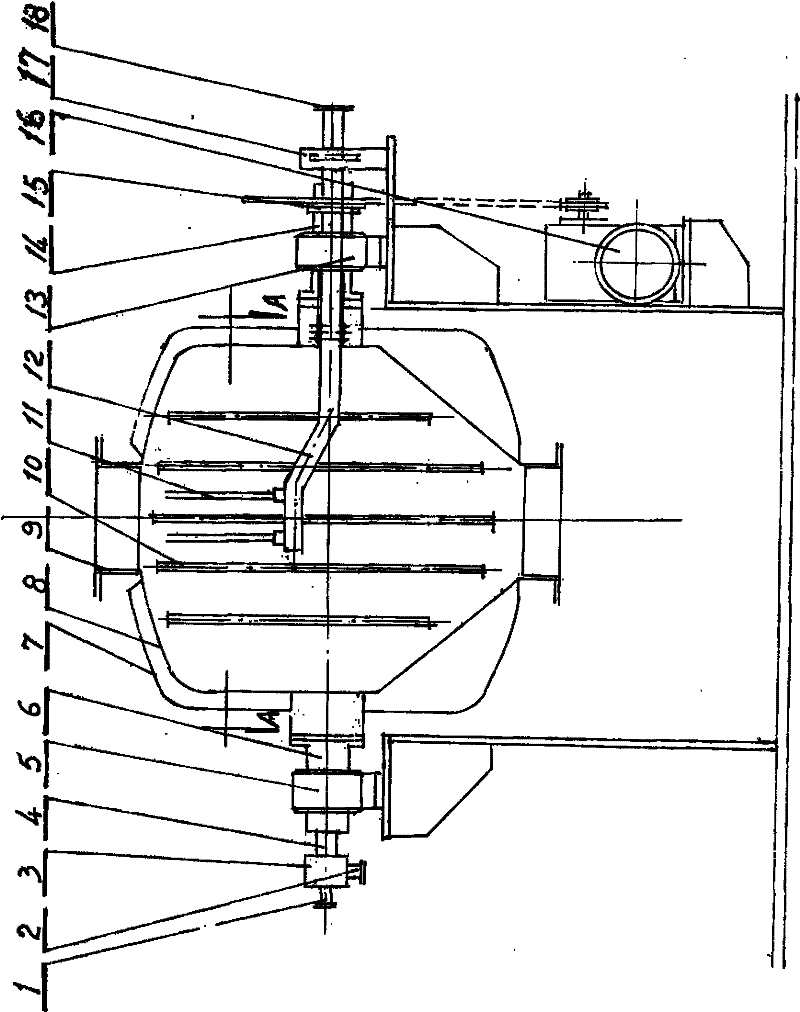

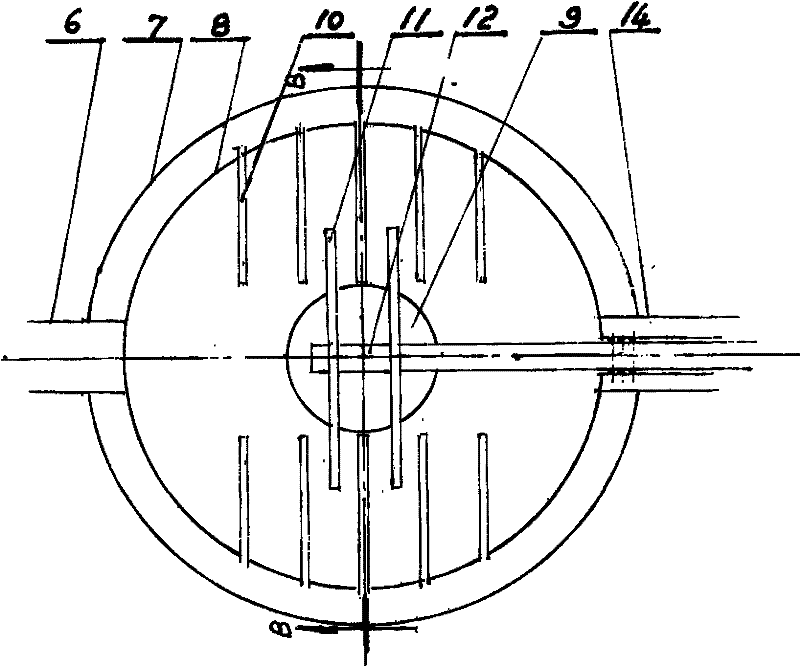

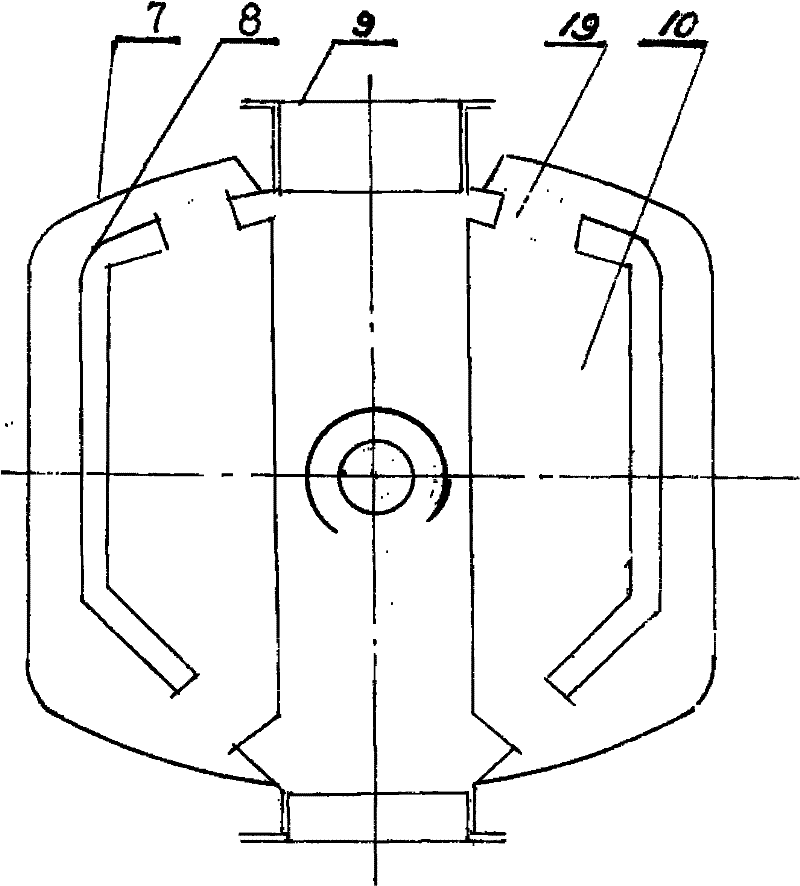

[0009] Embodiments of the present invention will be further described in conjunction with the accompanying drawings, by figure 1 , 2 , 3, the single-cone vacuum dryer includes a steam inlet (1), a steam condensate outlet (2), a steam rotary joint (3), a steam condensate main pipe (4), a left bearing seat (5), a left rotating shaft (6), steam heating jacket (7), inner cylinder body (8), manhole (9), inner heating plate (10), exhaust gas filter plate (11), exhaust gas extraction pipe (12), right bearing seat ( 13), right rotating shaft (14), driving sprocket wheel (15), driving machine (16), air extraction pipe holder (17) and air extraction port (18) etc. are formed. Its characteristics are: the inner cylinder (8) is composed of two parts with an elliptical head at one end and a cone at the other end; both ends of the steam heating jacket (7) are composed of elliptical heads; There are multiple inner heating plates (10), the left and right rotation shafts (6, 14) are fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com