Compound single cone bit

A single-cone, compound technology, applied to drill bits, drilling equipment, earthwork drilling and mining, etc., can solve the problems of drill bit mechanical penetration rate reduction, drill bit life reduction, cutting tooth wear, etc., to achieve enhanced rock breaking efficiency and improved breaking efficiency. Rock efficiency, load reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

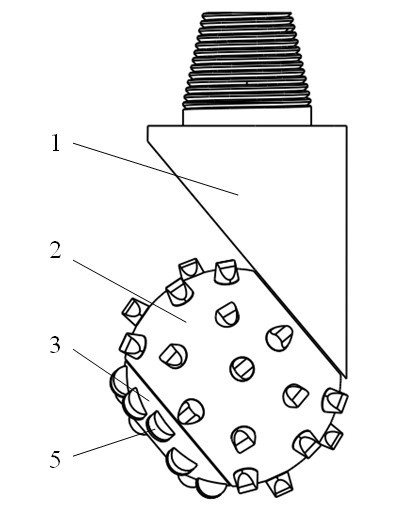

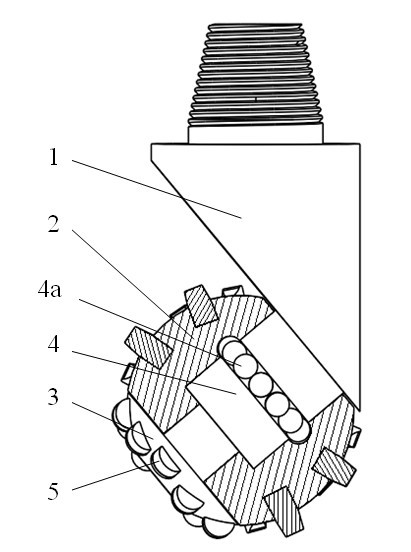

[0027] Such as figure 1 , 3 , shown in 5 and 6: a compound single cone bit, comprising a bit body 1, a cone 2, a cone point 3, the cone 2 and the cone point 3 are arranged with cutting teeth 5, the drill bit The body 1 is provided with a journal 4 , and the cone 2 is connected in rotation with the journal 4 , and the feature is that the cone tip 3 is fixedly connected with the front end of the journal 4 .

[0028] The cutting teeth 5 on the gear tip 3 are polycrystalline diamond composite sheets, polycrystalline diamond composite teeth, thermally stable polycrystalline diamond cutting teeth, natural diamond cutting teeth, impregnated diamond cutting teeth, carbide cutting teeth , cubic boron nitride cutters, ceramic cutters, cutters containing diamond or cubic boron nitride.

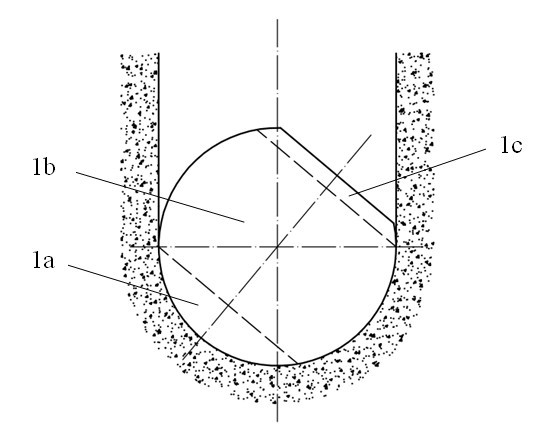

[0029] like Figure 7 shown When the drill bit is drilling, driven by the rotation of the bit body 1, the cone 2 revolves around the central axis of the drill bit and at the same time rotates around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com