Single-cone drier for feeding liquid continuously

A dryer and single-cone technology, applied in the field of liquid continuous feeding single-cone dryer, can solve the problems of unsatisfactory drying effect, low drying efficiency, limited application scope, etc. The effect of improving processing efficiency and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

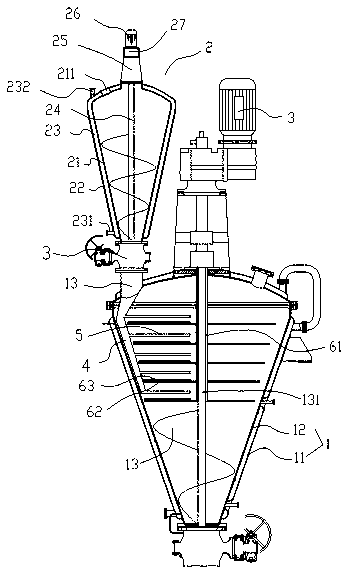

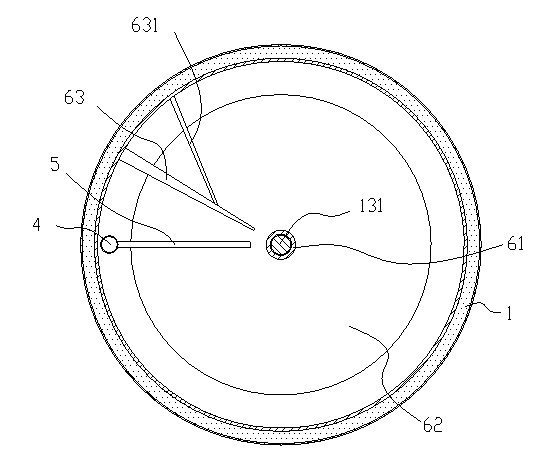

[0019] like figure 1 Shown, a kind of liquid continuous feeding single-cone drier, comprises the conical body 1 of the single head cone that is made up of insulation layer 11 and heating layer 12, is provided with screw propulsion type stirring paddle 13 in the body 1, stirs The paddle 13 is driven to rotate by the motor 3 arranged on the top of the body through the main shaft 131.

[0020] The dryer is provided with a first-line liquid pre-drying continuous feeding device, and the continuous feeding device includes two parts: a liquid flow structure and a pre-drying structure.

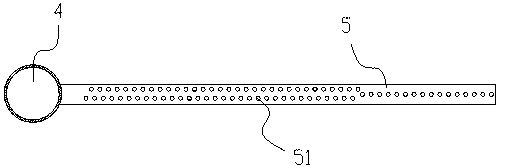

[0021] Wherein the liquid flow structure is arranged on the feed port 13 of the device body, which includes a feed barrel 2 with a feed port 211 that can heat the material into a liquid state. In this embodiment, the barrel body of the feed barrel 2 is composed of a heat-conducting inner cylinder 21 and an insulated outer cylinder 22. There is a gap between the inner and outer cylinders to form a pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com