Hydraulic Whipstock Anchor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

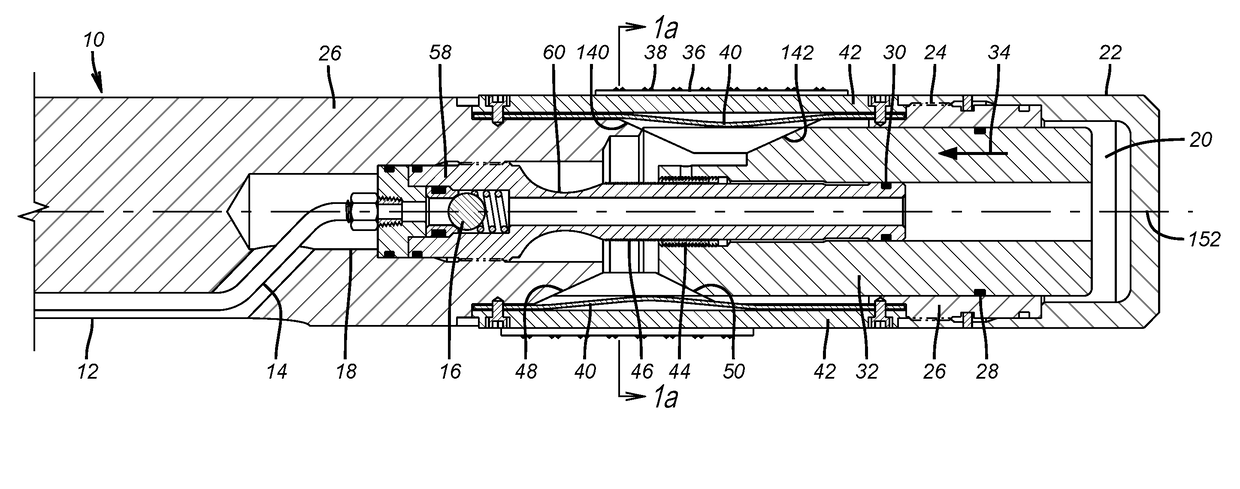

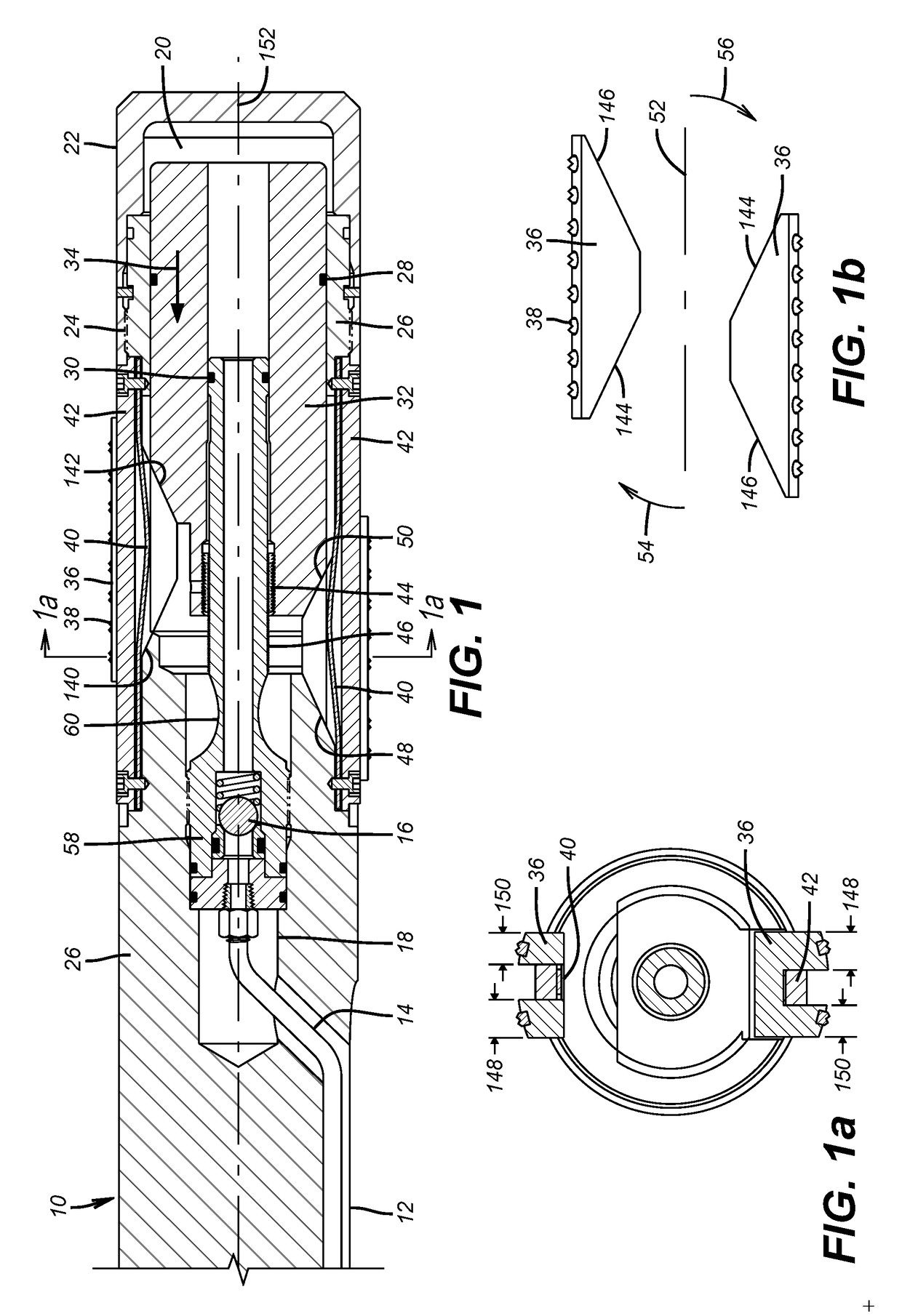

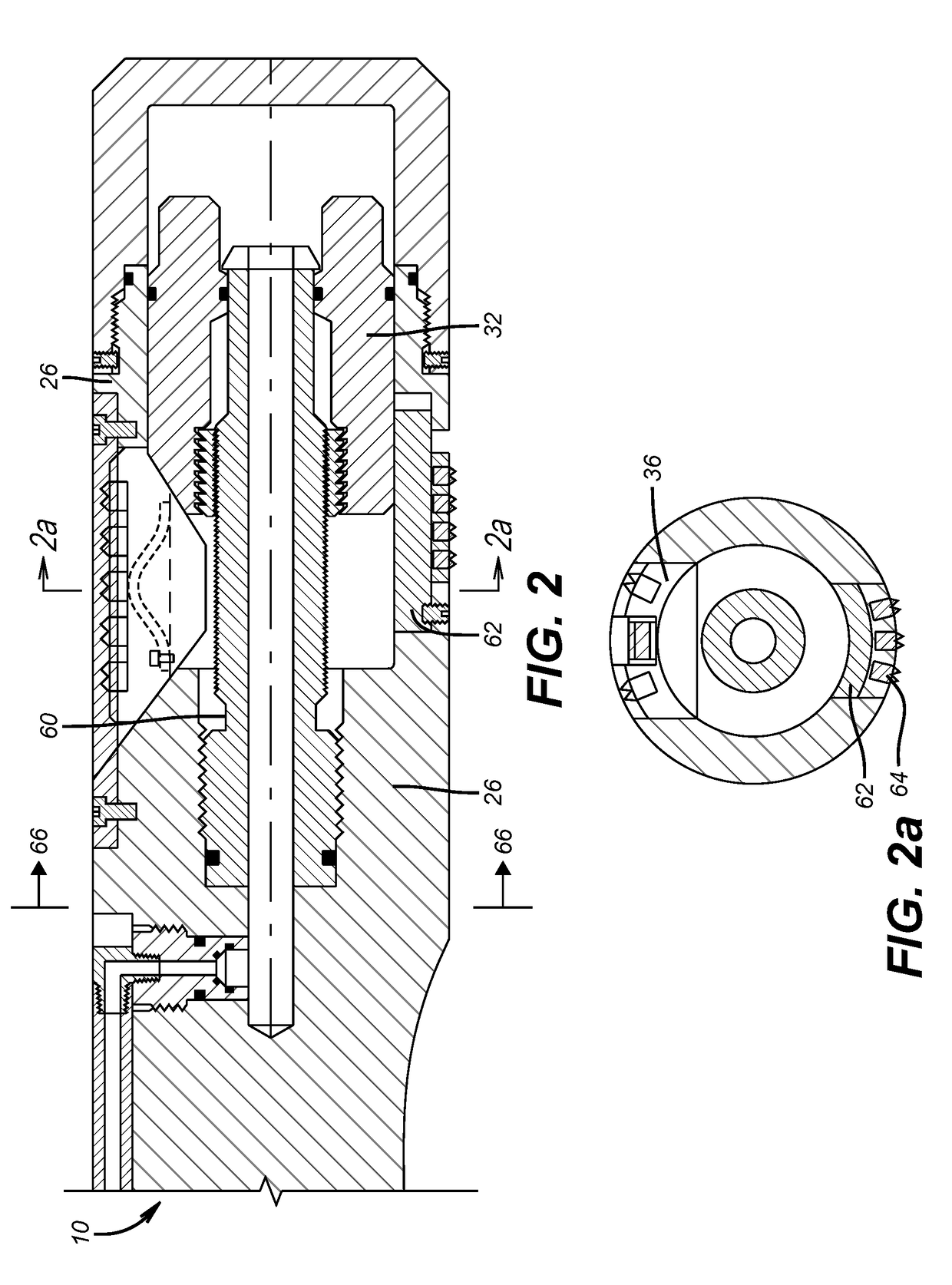

[0022]Referring to FIG. 1, a whipstock 10 has a ramp 12 and an associated hydraulic line 14 that typically is run behind the ramp 12 to protect the line 14 from the advancing window mill that is not shown. A check valve 16 in line 14 allows flow one way into passage 18 to chamber 20 defined by cap 22 secured at thread 24 to housing 26. Cone 32 is sealed with seals 28 and 30 so that built up pressure in chamber 20 moves cone 32 in the direction of arrow 34 toward the housing 26. Two slips 36 are shown at 180 degree spacing although different spacing and number of slips is contemplated. The slips 36 have external carbide or hardened inserts 38 to dig into the surrounding tubular that is not shown to support the whipstock 10. A biasing spring 40 pushes between a respective slip 36 and a retainer 42 that limits the outward travel of each slip 36. A lock ring 44 is moved along ratchet profile 46 as cone 32 moves in the direction of arrow 34 to prevent reverse movement of the cone 32. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com