KDP crystalloid long-seed crystal single-cone growth method

A growth method and crystal growth technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of difficult growth, large growth solution disturbance, large growth stress, etc., and achieve high optical quality, high cutting efficiency, The effect of high optical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: KDP crystal long seed crystal single cone growth

[0026] KDP crystal long seed crystal single cone growth, including the following steps:

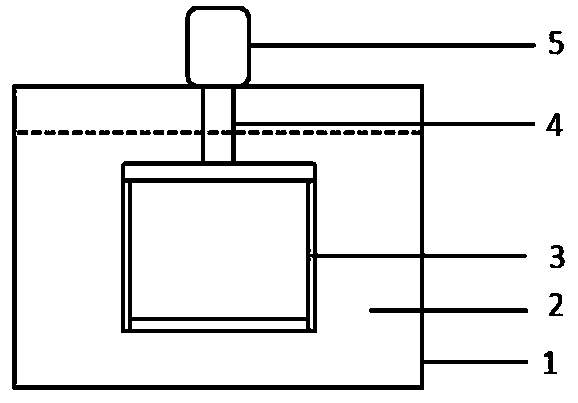

[0027] 1) Make the growth tank 1 used for crystal growth, the top of the growth tank 1 is equipped with a motor 5, the lower end of the rotating shaft 4 of the motor 5 is connected to the connecting rod 6 of the crystal carrier 3;

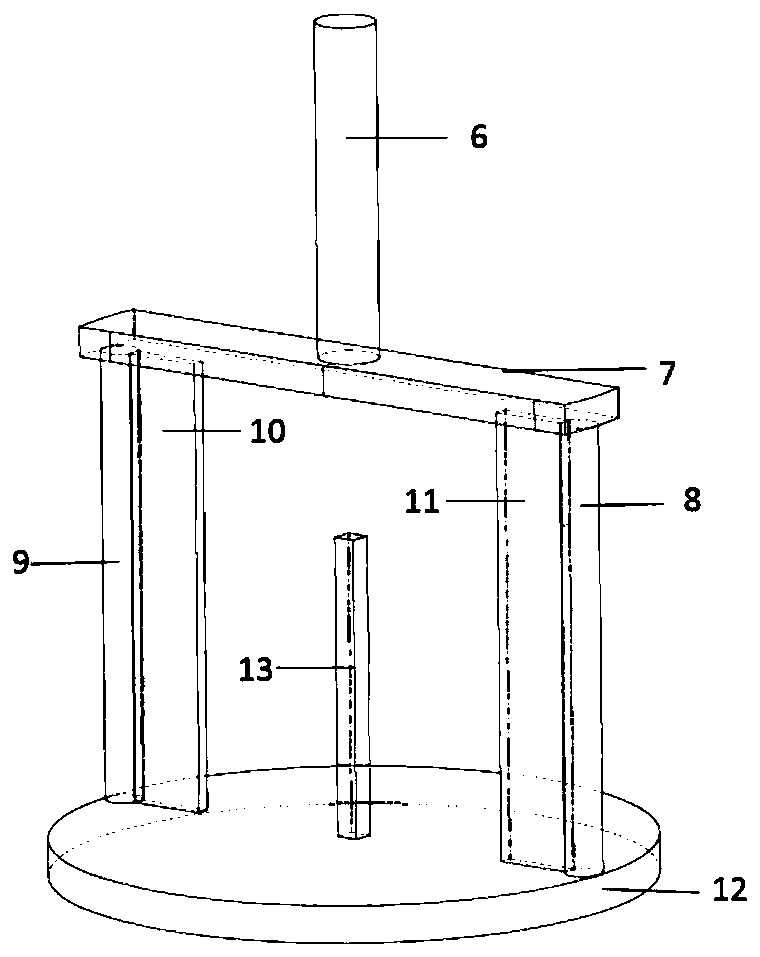

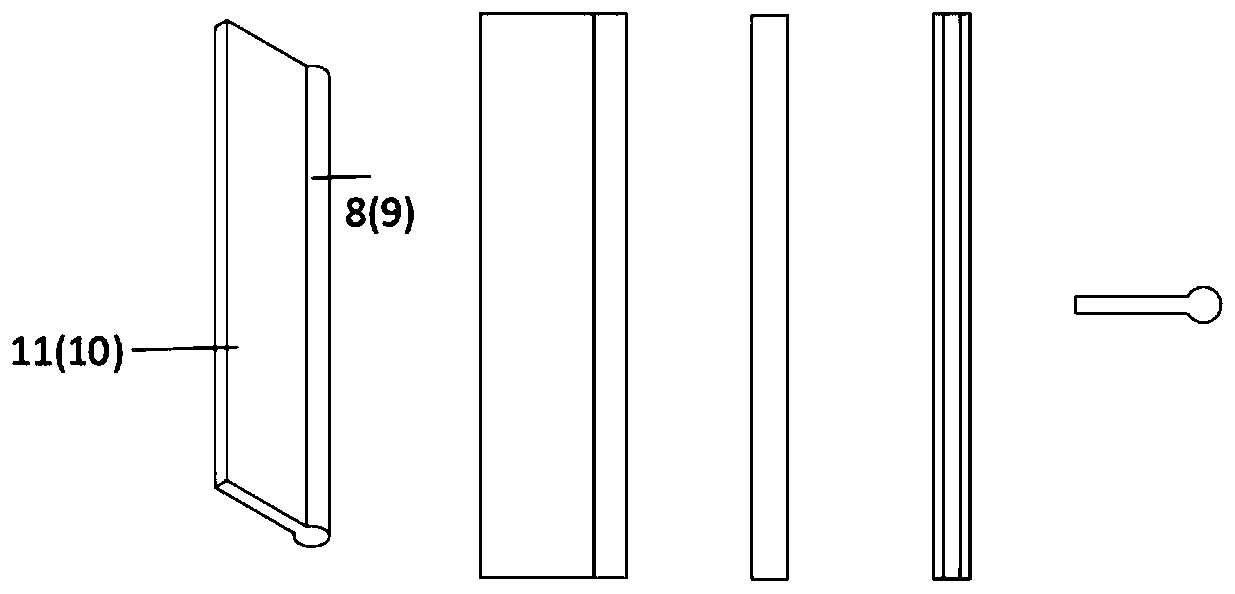

[0028] 2) making the crystal carrier 3 used for crystal growth: the crystal carrier 3 includes an upper beam 7, a lower tray 12, a connecting rod 6, supporting side bars 8, 9 and two leaf-shaped stirring paddles 10, 11, the The upper beam 7 is a slat with smooth edges and corners, the connecting rod 6 is a hollow round rod fixed in the middle of the upper beam 7, the lower tray 12 is a circular plate, and the supporting side bars 8, 9 The lower ends are welded to both ends of the same diameter of the lower tray 12, the upper ends of the support side bars 8,9 are welded to the two ends of ...

Embodiment 2

[0036] Embodiment 2: DKDP crystal long seed crystal single cone growth of 30% deuteration rate

[0037] 30% deuteration rate DKDP crystal long seed crystal single cone growth, including the following steps:

[0038] 1) Make the growth tank 1 used for crystal growth, the top of the growth tank 1 is equipped with a motor 5, the lower end of the rotating shaft 4 of the motor 5 is connected to the connecting rod 6 of the crystal carrier 3;

[0039]2) making the crystal carrier 3 used for crystal growth: the crystal carrier 3 includes an upper beam 7, a lower tray 12, a connecting rod 6, supporting side bars 8, 9 and two leaf-shaped stirring paddles 10, 11, the The upper beam 7 is a slat with smooth edges and corners, the connecting rod 6 is a hollow round rod fixed in the middle of the upper beam 7, the lower tray 12 is a circular plate, and the supporting side bars 8, 9 The lower ends are welded to both ends of the same diameter of the lower tray 12, the upper ends of the suppor...

Embodiment 3

[0047] Embodiment 3: DKDP crystal long seed crystal single cone growth of 70% deuteration rate

[0048] 70% deuteration rate DKDP crystal long seed crystal single cone growth, including the following steps:

[0049] 1) Make the growth tank 1 used for crystal growth, the top of the growth tank 1 is equipped with a motor 5, the lower end of the rotating shaft 4 of the motor 5 is connected to the connecting rod 6 of the crystal carrier 3;

[0050] 2) making the crystal carrier 3 used for crystal growth: the crystal carrier 3 includes an upper beam 7, a lower tray 12, a connecting rod 6, supporting side bars 8, 9 and two leaf-shaped stirring paddles 10, 11, the The upper beam 7 is a slat with smooth edges and corners, the connecting rod 6 is a hollow round rod fixed in the middle of the upper beam 7, the lower tray 12 is a circular plate, and the supporting side bars 8, 9 The lower ends are welded to both ends of the same diameter of the lower tray 12, the upper ends of the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com