Remote control linearly regulated fuel valve

a fuel valve and remote control technology, applied in the field of valve construction, can solve the problems of burner generating a larger flame, increasing heat, and not generally allowing intermediate settings of fuel output by the user,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

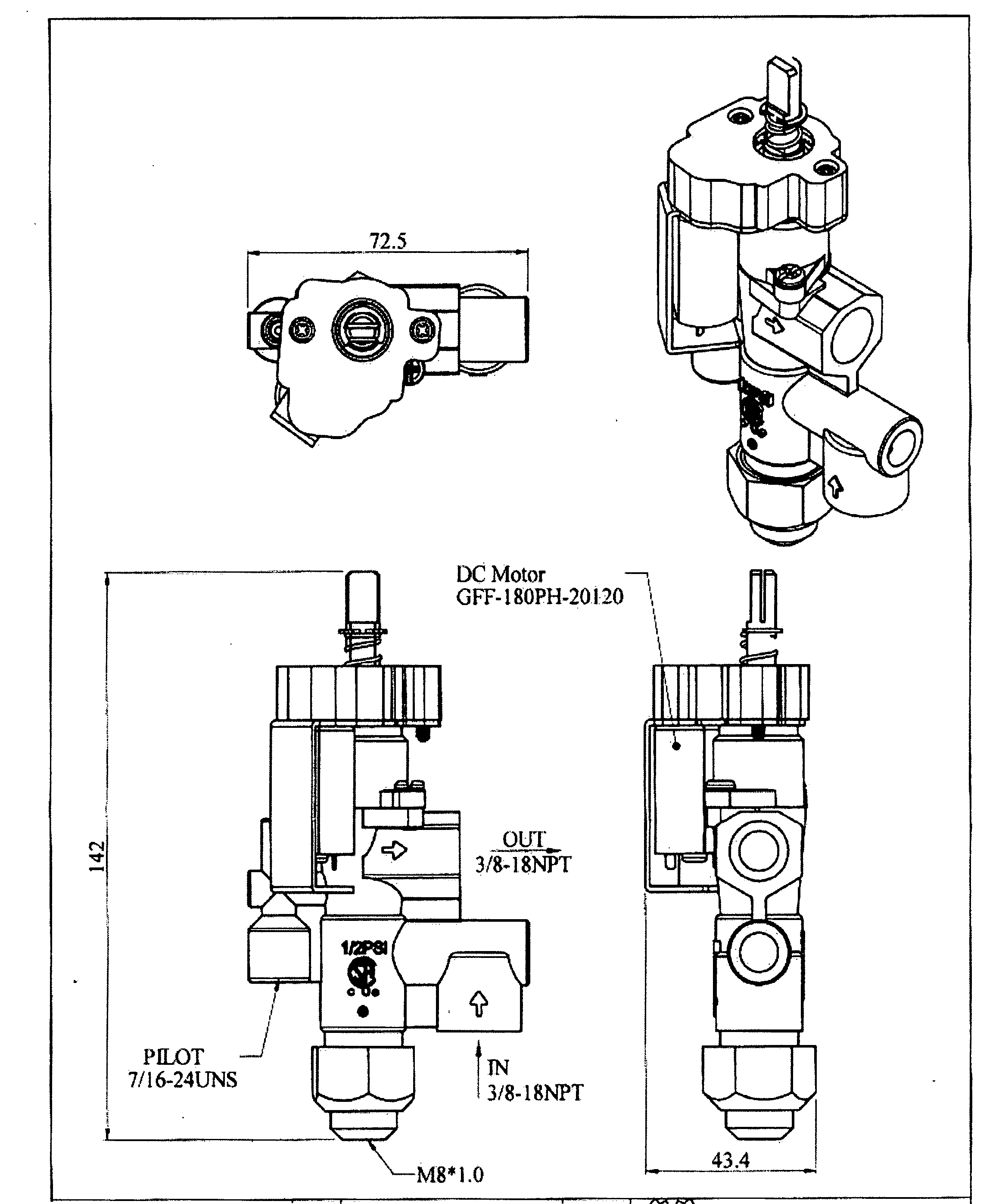

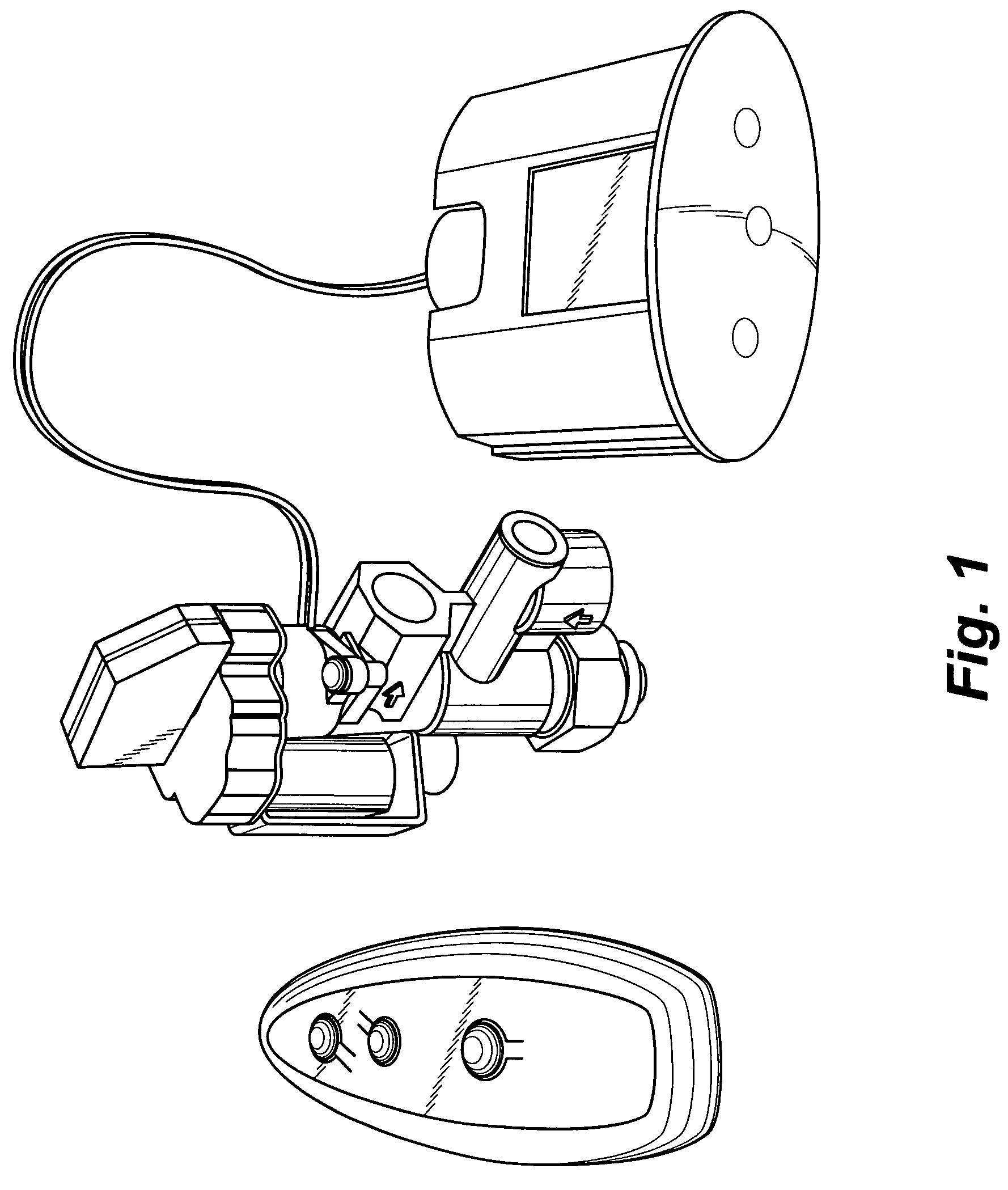

[0030]The present invention generally relates to the construction of valves such as are used to control the flow of combustible gas fired appliances and more particularly pertains to improvements in the configuration and construction of such valves in order to effect linear regulation of gas flow to the burner unit.

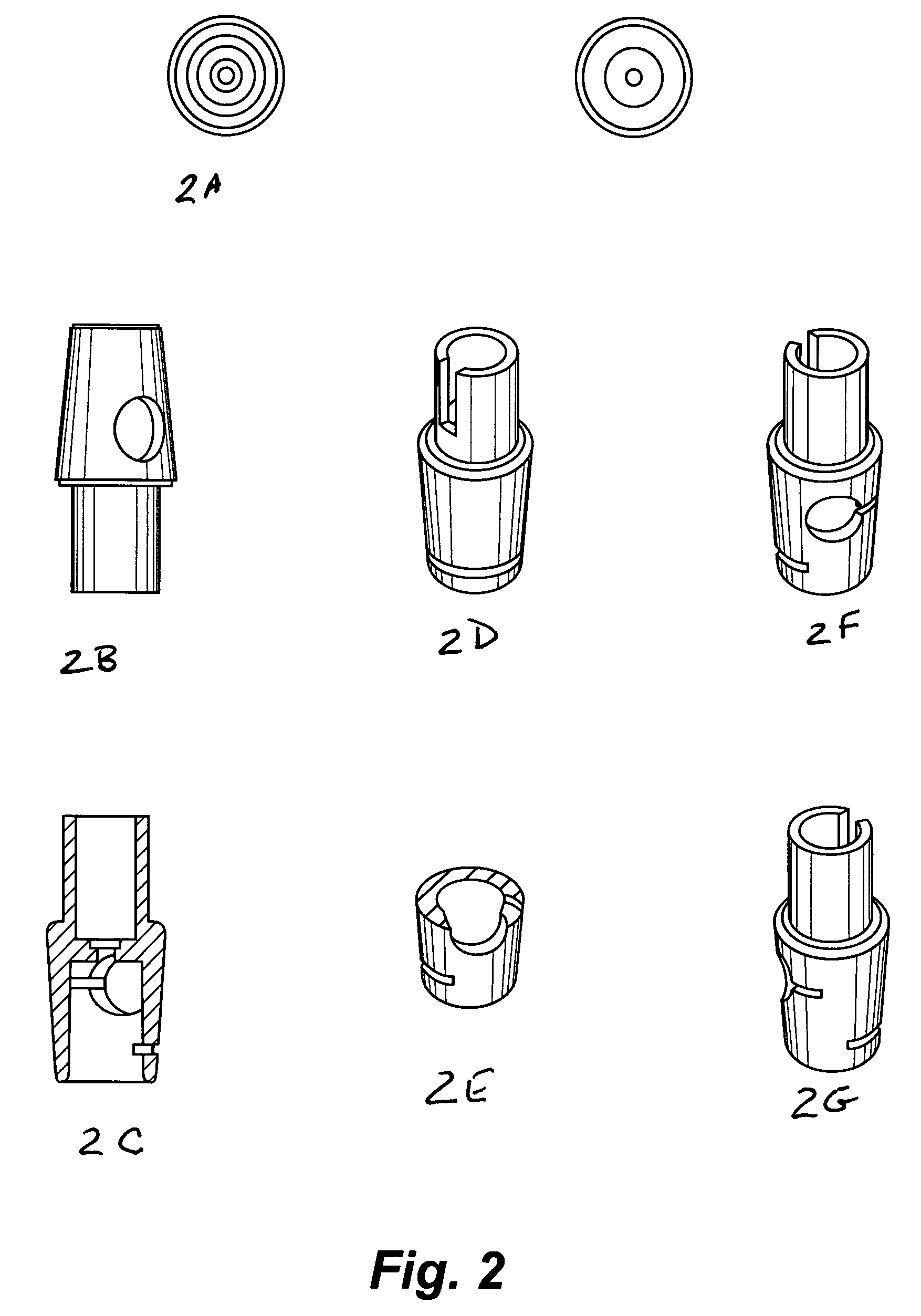

[0031]Conventional design of valve cones in a manual gas valve typically provide a single opening for the flow of fuel. The single opening of cone accordingly limits gas flow to either Low or High output.

[0032]The unique slotted cone of present invention achieves an even linear adjustment of fuel flow. The slot of the cone is rotated for Low, Medium, and High settings to achieve gas flow to main burner at a steady flow rate.

[0033]In more detail, the present invention provides a gas valve that includes a slotted conical rotatable plug component shown most clearly in FIG. 2, that is received in a conical cavity formed in a valve body having an effective seal therebetween. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com