Cone single roller bit

A single-cone, conical technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve the impact of single-cone bit performance and range, low average ROP and life of roller-cone bits, tooth wear, etc. The problem is to increase the surface area of the cone, prolong the effective service life, and reduce the scraping distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

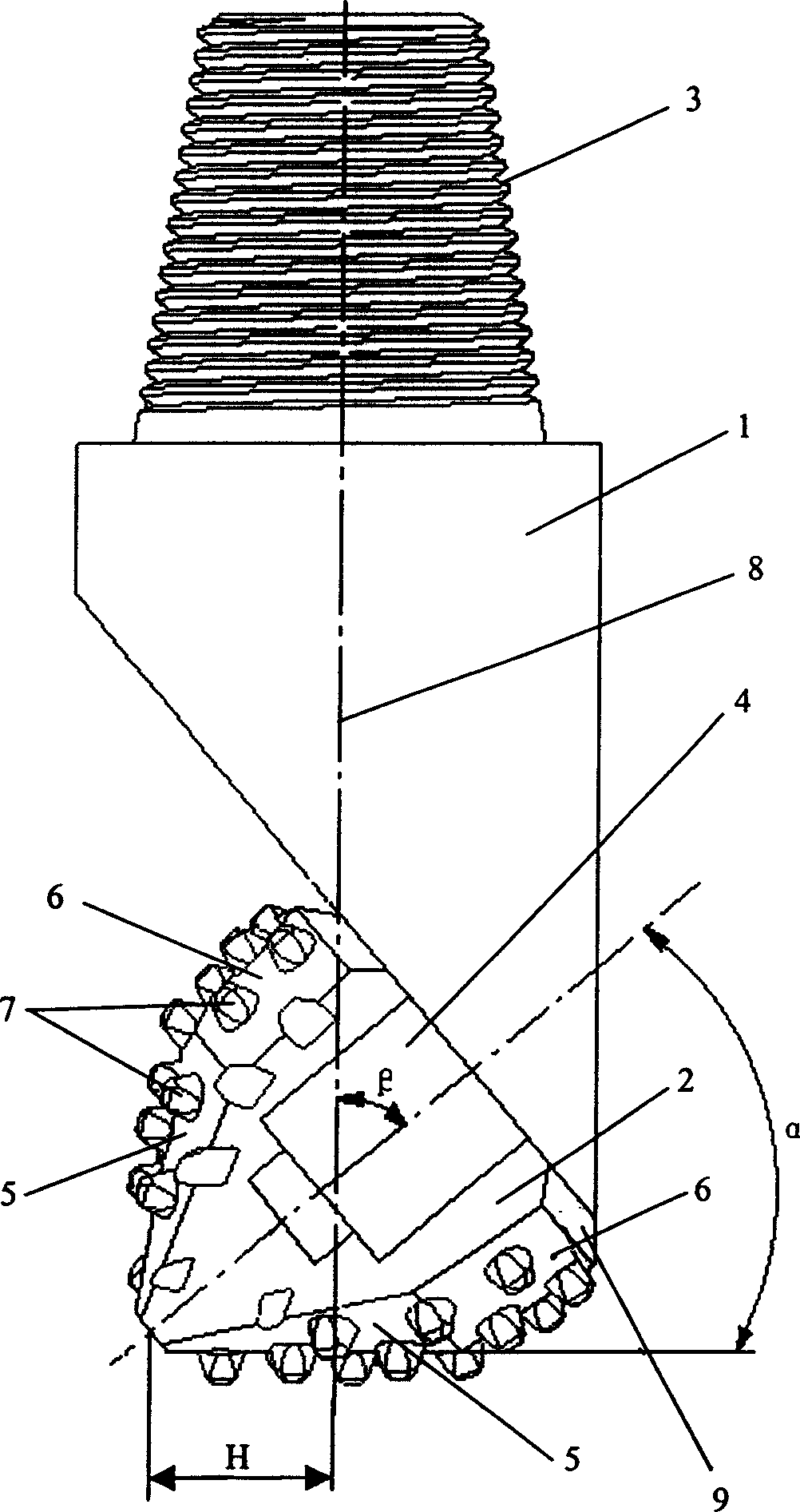

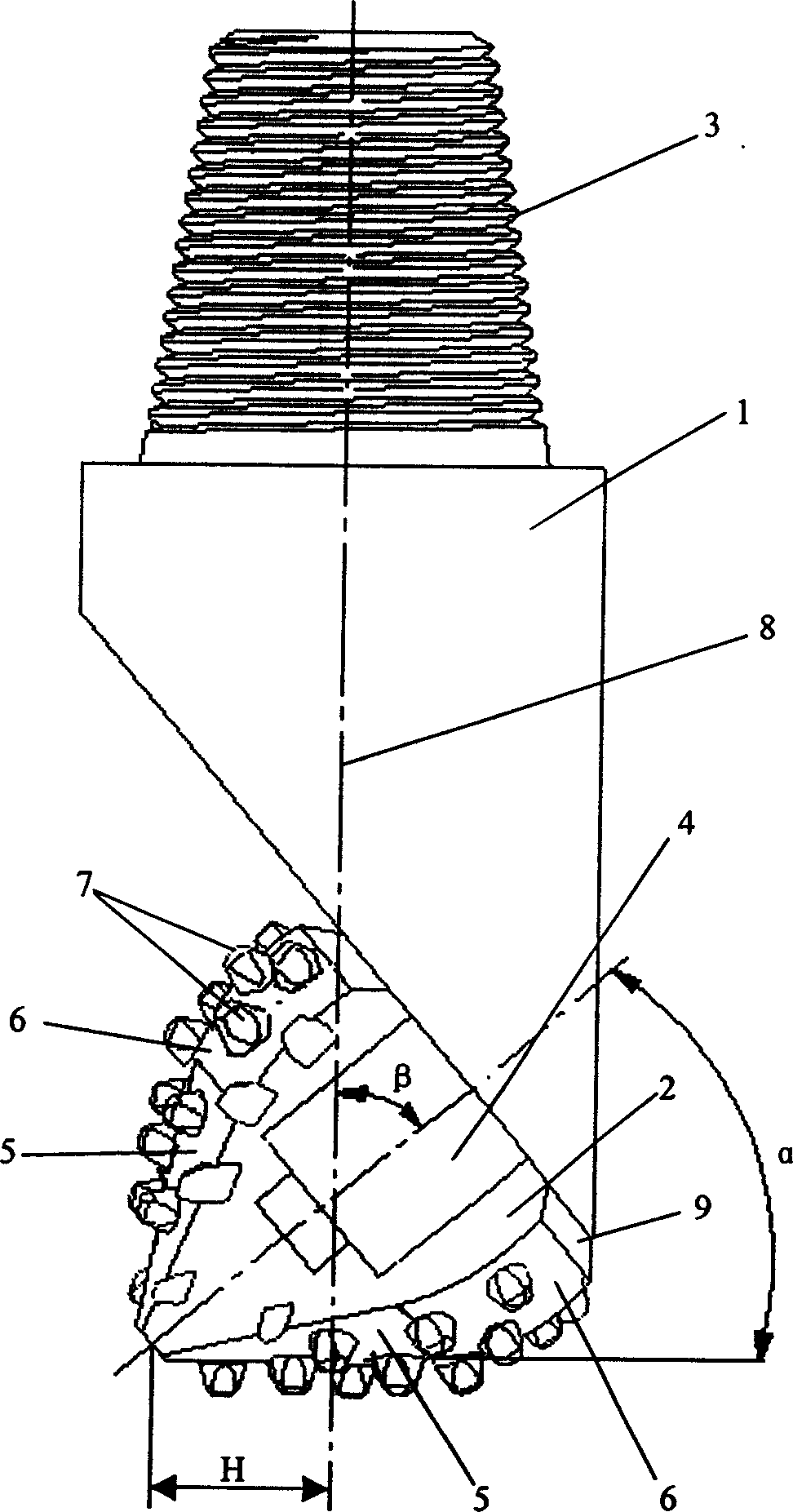

[0011] The first example is figure 1 As shown, it includes a drill bit body 1 and a cone 2, the upper part of the drill bit body is provided with a connecting thread 3, the lower end of the drill bit body has an inclined surface, and the inclined surface is provided with a tooth palm journal 4, and the axis of the tooth palm journal is perpendicular to the inclined surface. The included angle β with the rotation axis 8 of the bit body is 40-50°. The cone is movably connected with the bit body through the palm journal. The surface of the cone is provided with a main tooth surface 5 and an auxiliary tooth surface 6. A back cone surface 9 is provided; the main cloth tooth surface 5 is a conical surface, and the angle α formed by the generatrix of the conical surface and the axis of the palm journal is 40-50°, and the axis of the journal of the tooth palm an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com