Mycelium pellet biosorption and regeneration method

A technology of biosorption and mycelium balls, applied in separation methods, filter regeneration, sustainable biological treatment, etc., can solve the problems of impractical treatment of dye wastewater, failure to reflect the decolorization performance of dyes, etc., and achieve easy sedimentation and stable treatment , the effect of efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

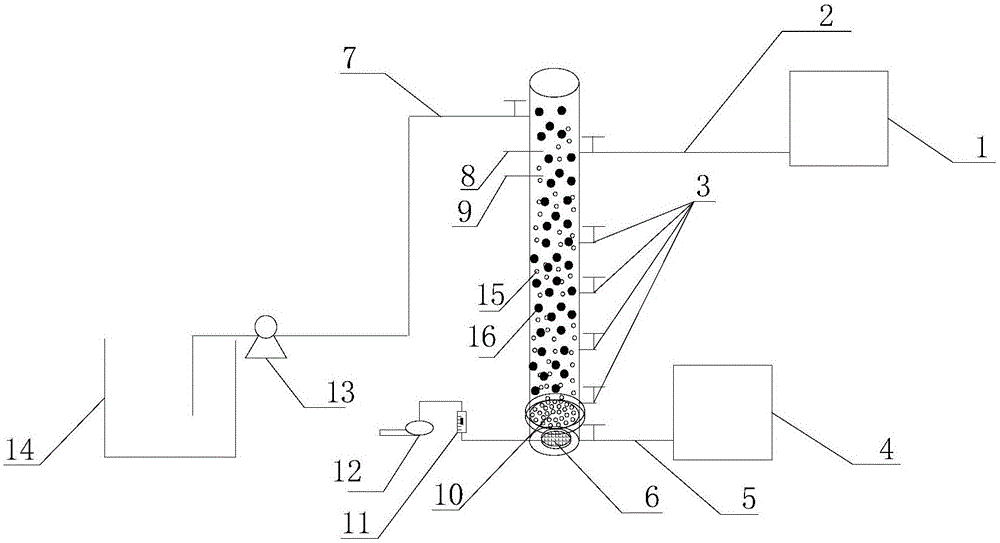

Image

Examples

Embodiment 1

[0025] The biosorption and regeneration method of mycelium balls in this embodiment includes preparation of mycelium balls, biosorption and regeneration of mycelial balls;

[0026] The preparation of the mycelium ball: including the configuration of the ball forming medium and the cultivation of the mycelium ball;

[0027] Preparation of ball-forming medium: adopt the following ingredients to make ball medium: potato juice prepared according to the ratio of 200g potatoes: 1L water, glucose 20g / L, NaCl1.0g / L, (NH 4 ) 2 SO 4 1.0g / L, KH 2 PO 4 0.5g / L and CaCl 2 0.05g / L; adjust the sphere-forming medium to acidic sphere-forming medium;

[0028] The preparation process of the potato juice is as follows: cut the potatoes into pieces, mix the potato pieces with water at a ratio of 200g / L, boil the water for 30 minutes, filter out the solids to obtain potato juice, add water to the potato juice, and make the diluted Potato juice is equal to the initial water volume.

[0029] Cu...

Embodiment 2

[0048] The difference between this example and Example 1 is that in the method for biosorption and regeneration of mycelium balls in this example, the aeration time in the biosorption step lasts for 12 hours.

[0049] In this embodiment, the aeration time of 12 hours is adopted, which is suitable for the situation where the dye content in the wastewater is low.

Embodiment 3

[0051] The difference between this embodiment and the above embodiment is that in the method for biosorption and regeneration of mycelium balls in this embodiment, the aeration time in the biosorption step lasts for 18 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com