Ion exchange membrane with high impurity tolerance

A technology of ion exchange membrane and tolerance, applied in the field of ion membrane, can solve the problems of impurity retention, electrolysis voltage rise, difficult to remove, etc., and achieve the effect of maintaining stability, high current efficiency, and high impurity tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

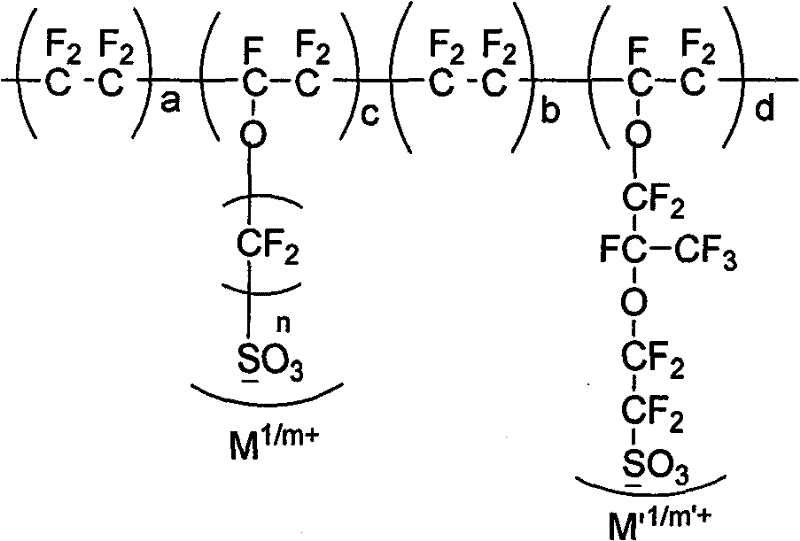

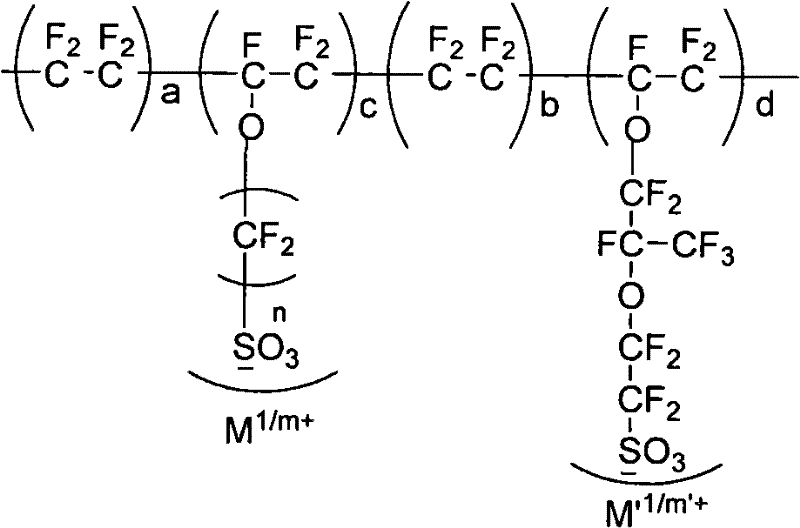

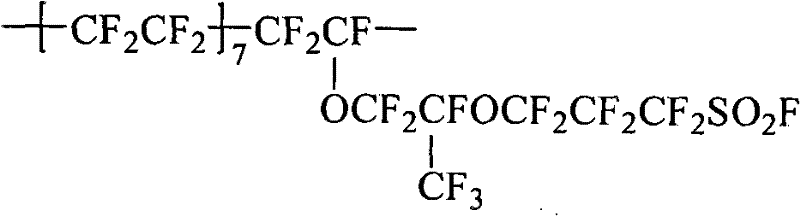

[0035] Water and ethanol are formulated into a mixed solution according to a weight ratio of 1:1, and then the structure is:

[0036]

[0037] Among them, (a+b) / (a+b+c+d)=0.65; (c+d) / (a+b+c+d)=0.35

[0038] The fluorine-containing sulfonic acid resin is dissolved into the water-alcohol mixture to form a sulfonic acid resin solution with a concentration of 2wt%; then zirconia particles with an average particle size of 0.2 microns are added to the above solution, and they are homogenized in a ball mill to form A dispersion with a content of 17% by weight. Using the method of spraying, the dispersion liquid is attached to the surface of both sides of the sulfonic acid / carboxylic acid composite membrane reinforced with grid cloth with a thickness of 110 microns. After drying, a discontinuous porous gas release layer with a porosity of 84% is formed. The distribution of zirconium particles on the surface of the composite film is 7.6mg / cm 2 .

[0039] The above membrane was im...

Embodiment 2

[0048] Water and ethanol are formulated into a mixed solution according to a weight ratio of 1:1, and then the structure is:

[0049]

[0050] Among them, (a+b) / (a+b+c+d)=0.86; (c+d) / (a+b+c+d)=0.14;

[0051] The fluorine-containing sulfonic acid resin is dissolved into the water-alcohol mixture to form a sulfonic acid resin solution with a concentration of 10%; then silicon oxide particles with an average particle size of 0.3 microns are added to the above solution, and they are homogenized in a ball mill to form 14% by weight dispersion. Using the method of roller coating, the dispersion liquid is attached to the surface of both sides of the sulfonic acid / sulfonic acid composite membrane reinforced by non-woven fabric with a thickness of 110 microns, and a discontinuous porous gas release layer with a porosity of 66% is formed after drying. The distribution of silicon oxide particles on the surface of the composite film is 5.7mg / cm 2 .

[0052] Using the same method as in...

Embodiment 3

[0056] Water and ethanol are formulated into a mixed solution according to a weight ratio of 1:1, and then the structure is:

[0057]

[0058] Among them, (a+b) / (a+b+c+d)=0.77; (c+d) / (a+b+c+d)=0.23;

[0059] The fluorine-containing sulfonic acid resin is dissolved into the water-alcohol mixture to form a sulfonic acid resin solution with a concentration of 0.5%; then tin oxide particles with an average particle diameter of 0.2 microns are added to the above solution, and are homogenized in a ball mill to form 8% by weight dispersion. Using the method of brushing, the dispersion liquid is attached to the cathode side surface of the fiber-reinforced sulfonic acid / sulfonic acid carboxylic acid copolymer / carboxylic acid composite membrane with a thickness of 110 microns, and after drying, a non-woven fabric with a porosity of 90% is formed. Continuous porous gas release layer, the distribution of tin oxide particles on the surface of the composite film is 3mg / cm 2 .

[0060]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com