Polymer resin composition for preparing hollow fiber membrane, preparation method of hollow fiber membrane, and hollow fiber membrane

A resin composition, polymer technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve problems such as shortening membrane life, and achieve high water permeability, improved strength and chemical resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

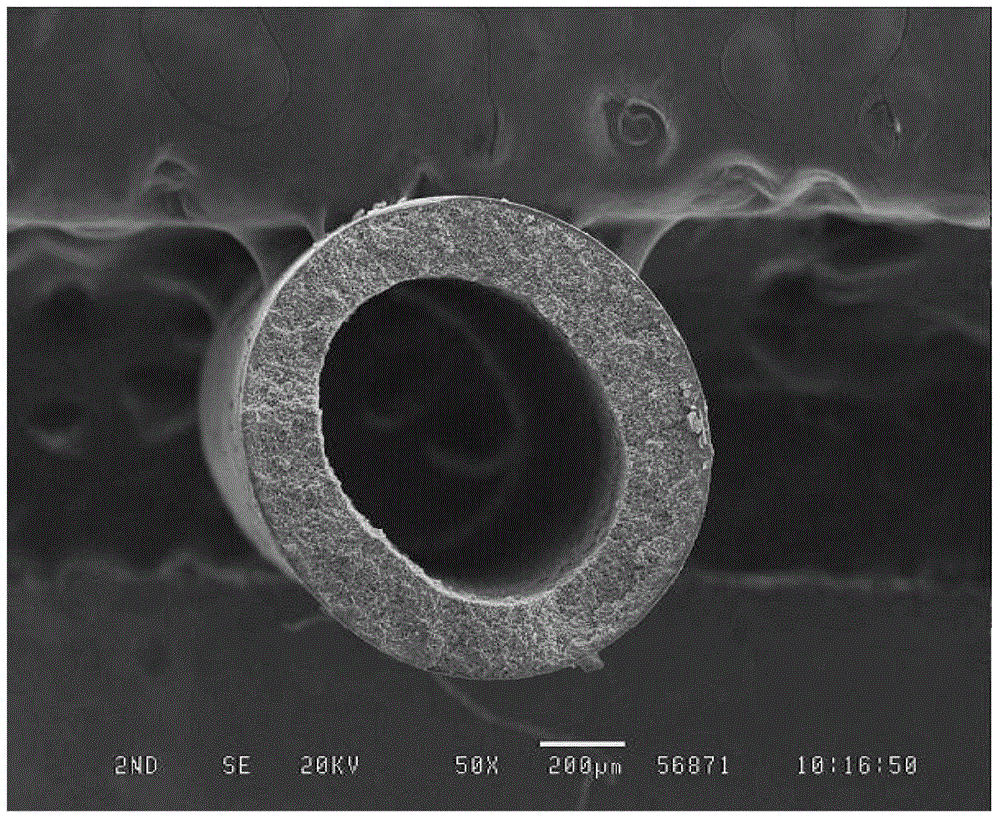

[0086] Contains 40% by weight of a combined amount of polyvinylidene fluoride resin (PVDF) and cis-endo-bicyclo[2.2.1]heptane 2,3-dicarboxylate disodium, 10% by weight A polymer resin composition of N-methyl-2-pyrrolidone and 50% by weight of γ-butyrolactone was mixed at 170°C for 3 hours to prepare a spinning solution. At this time, the content of disodium cis-endo-bicyclo[2.2.1]heptane 2,3-dicarboxylate in the polymer resin composition was 2,000 ppmw.

[0087] The spinning solution thus prepared together with the internal coagulant is delivered to the nozzle. A mixture of N-methyl-2-pyrrolidone / polyethylene glycol (PEG) in a weight ratio of 1:1 was used as an internal coagulant. The coagulation bath is filled with water, and the height of the water in the coagulation bath and the nozzle are separated by 4 cm. The temperature of the coagulation bath is maintained at 5°C, and water is periodically circulated in it.

[0088] The PVDF hollow fiber separation membrane undergoing ph...

Embodiment 2

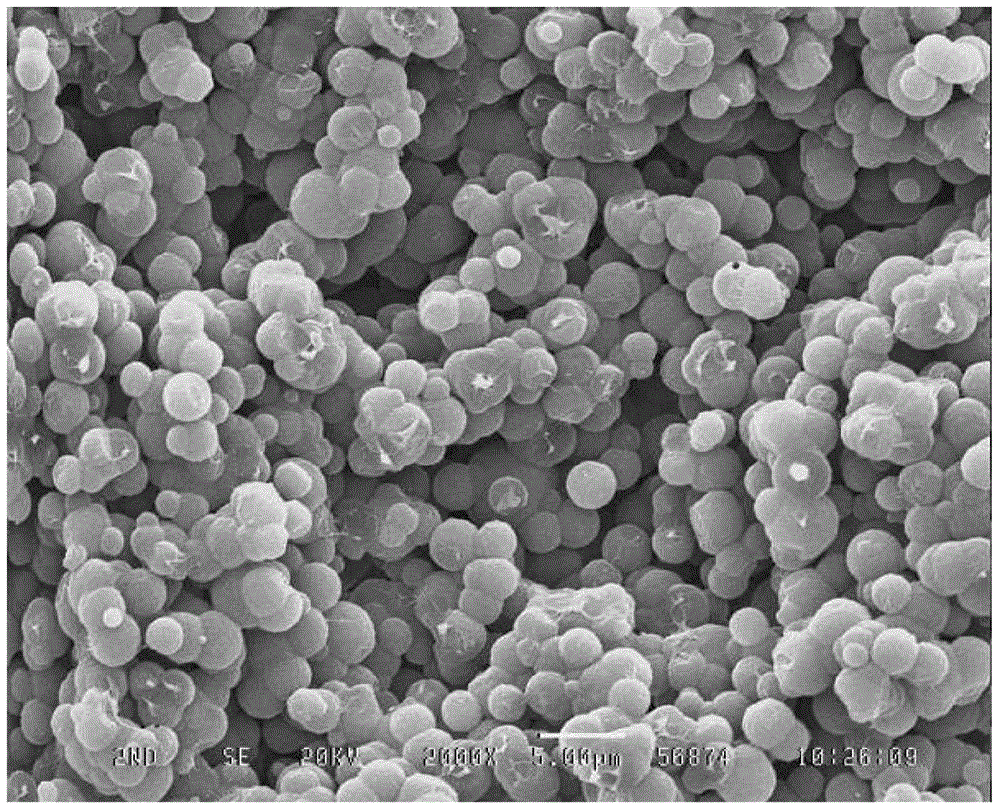

[0090] Except that the content of disodium cis-endo-bicyclo[2.2.1]heptane 2,3-dicarboxylate in the polymer resin composition was 3,000 ppmw, the hollow was prepared in the same manner as in Example 1. Fiber membrane.

Embodiment 3

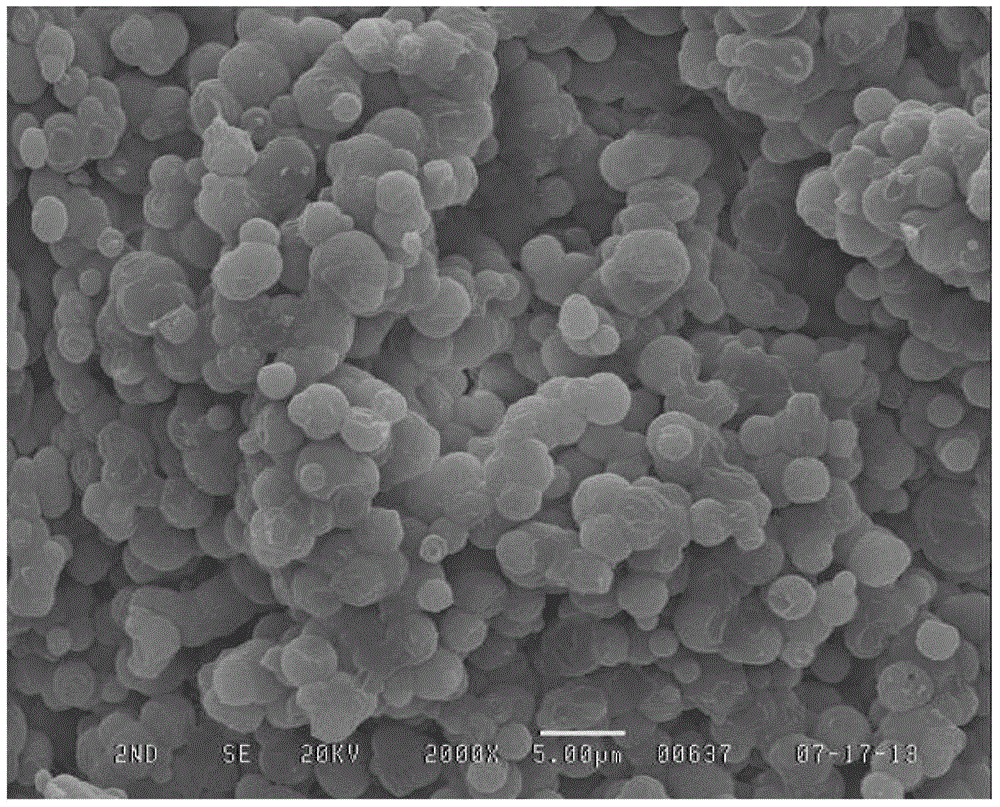

[0094] Contains 40% by weight combined amount of polyvinylidene fluoride (PVDF) resin and peroxide ((2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane)) , 10% by weight of N-methyl-2-pyrrolidone and 50% by weight of γ-butyrolactone polymer resin composition for preparing hollow fiber membranes are mixed at 170° C. for 3 hours Prepare spinning solution. At this time, the content of peroxide in the polymer resin composition is 300 ppmw.

[0095] The prepared spinning solution together with the internal coagulant is delivered to the nozzle. A mixture of N-methyl-2-pyrrolidone / polyethylene glycol (PEG) in a weight ratio of 1:1 was used as an internal coagulant. The coagulation bath is filled with water, and the height of the water in the coagulation bath and the nozzle are separated by 4 cm. The temperature of the coagulation bath is maintained at 5°C, and water is periodically circulated in it.

[0096] The PVDF hollow fiber separation membrane undergoing phase transfer in the coagulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com