Method for removing aluminum of aluminum powder vanadium-removing crude titanium tetrachloride mud

A technology of crude titanium tetrachloride and titanium tetrachloride, which is applied in the field of metallurgy, can solve the problems of high energy consumption, large environmental pollution, and high content of aluminum impurities, and achieve the effects of low energy consumption, simple operation, stable and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

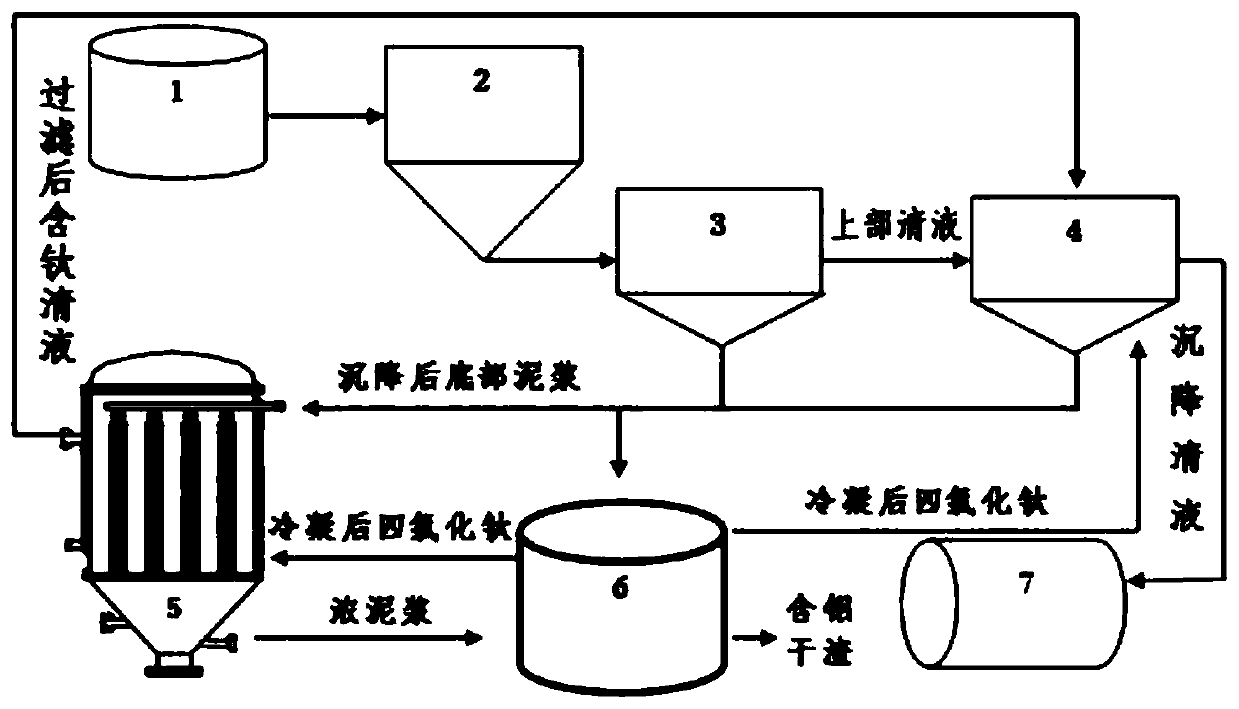

Image

Examples

Embodiment 1

[0044] For containing AlCl 3 Titanium tetrachloride mud with an impurity content of 3.58% is hydrolyzed, and the main composition of the material before hydrolysis is TiCl 4 , the impurity compositions are: FeCl 3 0.21%, AlCl 3 3.58%, VOCl 2 1.28%, TiCl 3 1.2%, and its solid content is 134g / L; the total amount of hydrolyzed materials in the hydrolysis tank is 19.5t, the controlled water addition is 40kg, and the hydrolysis time is 60min. During the hydrolysis process, the water is added mainly through the flow of mud in the hydraulic jet pump The generated negative pressure is automatically sucked into the hydrolysis tank, and the material after hydrolysis is directly discharged to the primary settling tank for settlement. The settling tank equipment is a thickener, and the settling time is set to 18 hours. (accounting for about 3 / 4 of the total sedimentation material) was discharged into the secondary settling tank and continued to settle for 8 hours, and the supernatant ...

Embodiment 2

[0049] For containing AlCl 3 Titanium tetrachloride slurry with an impurity content of 5.48% is hydrolyzed, and its main composition is TiCl 4 , the impurity compositions are: FeCl 3 0.36%, AlCl 3 5.48%, VOCl 2 1.76%, TiCl 3 It is 1.54%, and its solid content is 230g / L; the total amount of double hydrolyzed materials in the hydrolysis tank is 20t, the controlled water addition is 45kg, and the hydrolysis time is 60min. After hydrolysis, the settling time of the primary settling tank is 20h. After 20 hours, discharge the upper clear liquid of the primary settling tank into the secondary settling tank for 12 hours of further sedimentation, sample and analyze the upper clear liquid after the primary and secondary settling, and establish the impurity AlCl in the clear liquid titanium tetrachloride. 3 content, and the results are shown in Table 2.

[0050] Impurity composition before and after sedimentation in Table 2 Example 2

[0051] FeCl 3 / %

[0052] After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com