Fluorine-containing ion exchange membrane for alkali chloride electrolysis

A technology of alkali metal chlorides and ion exchange membranes, applied in the field of ion exchange membranes, can solve problems such as low interlayer bonding force and poor polymer compatibility, and achieve improved interlayer adhesion, increased bonding force, and increased interface compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Select IEC (exchange capacity) as perfluorosulfonic acid resin (CF) of 1.0mmol / g 2 = CFOCF 2 CF(CF 3 )OCF 2 CF 2 SO 2 A binary copolymer of F and tetrafluoroethylene) and a perfluorocarboxylic acid resin with an IEC of 0.9 mmol / g (CF 2 = CFOCF 2 CF(CF 3 )OCF 2 CF 2 COOCH 3 and tetrafluoroethylene binary copolymers) at a mass ratio of 5:5 at a temperature of 270°C for blending and granulation to obtain a fully mixed resin with an exchange capacity of 0.95mmol / g, in which the sulfonic acid functional group and carboxylic acid The functional group molar ratio is 10:9.

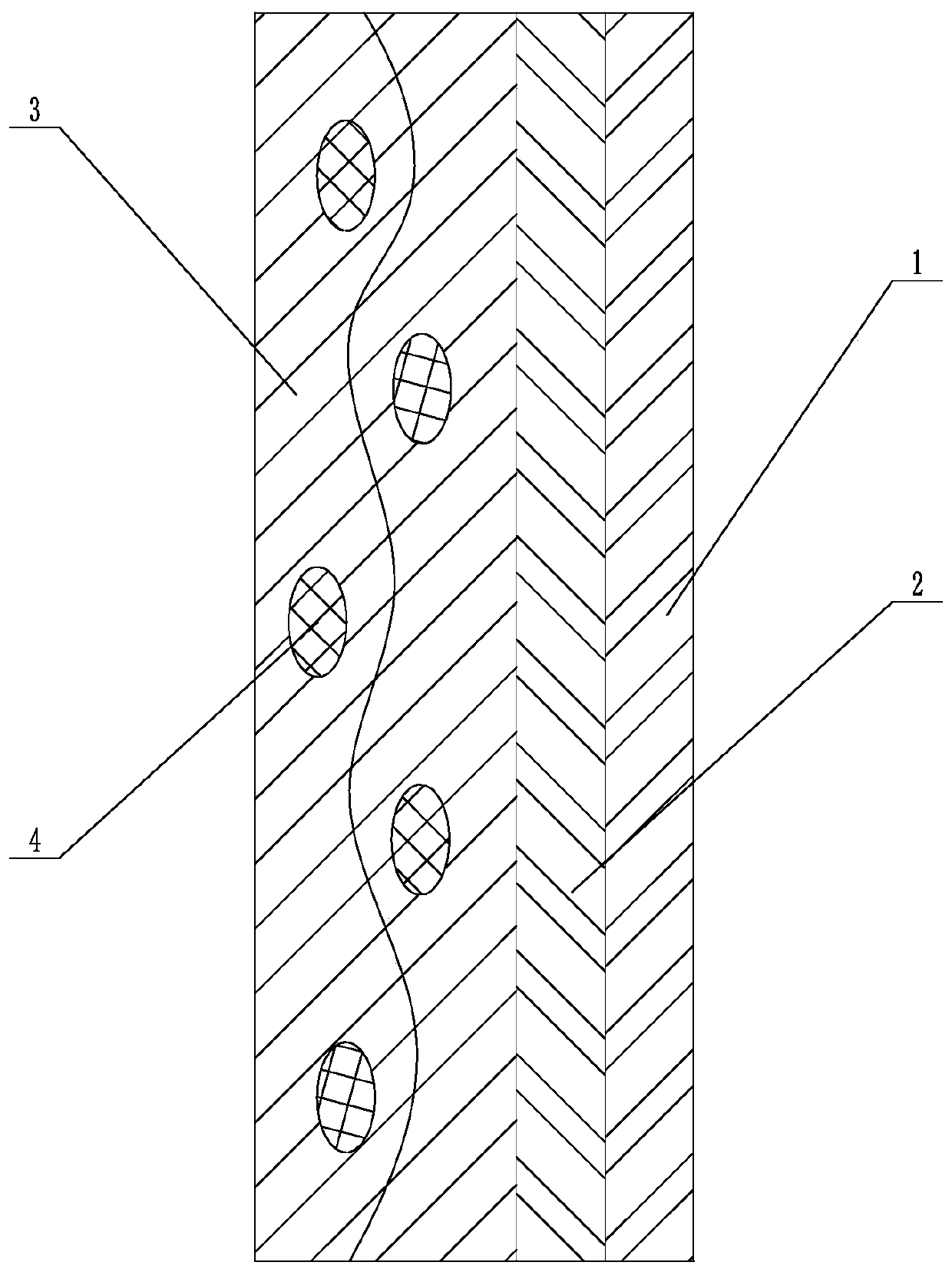

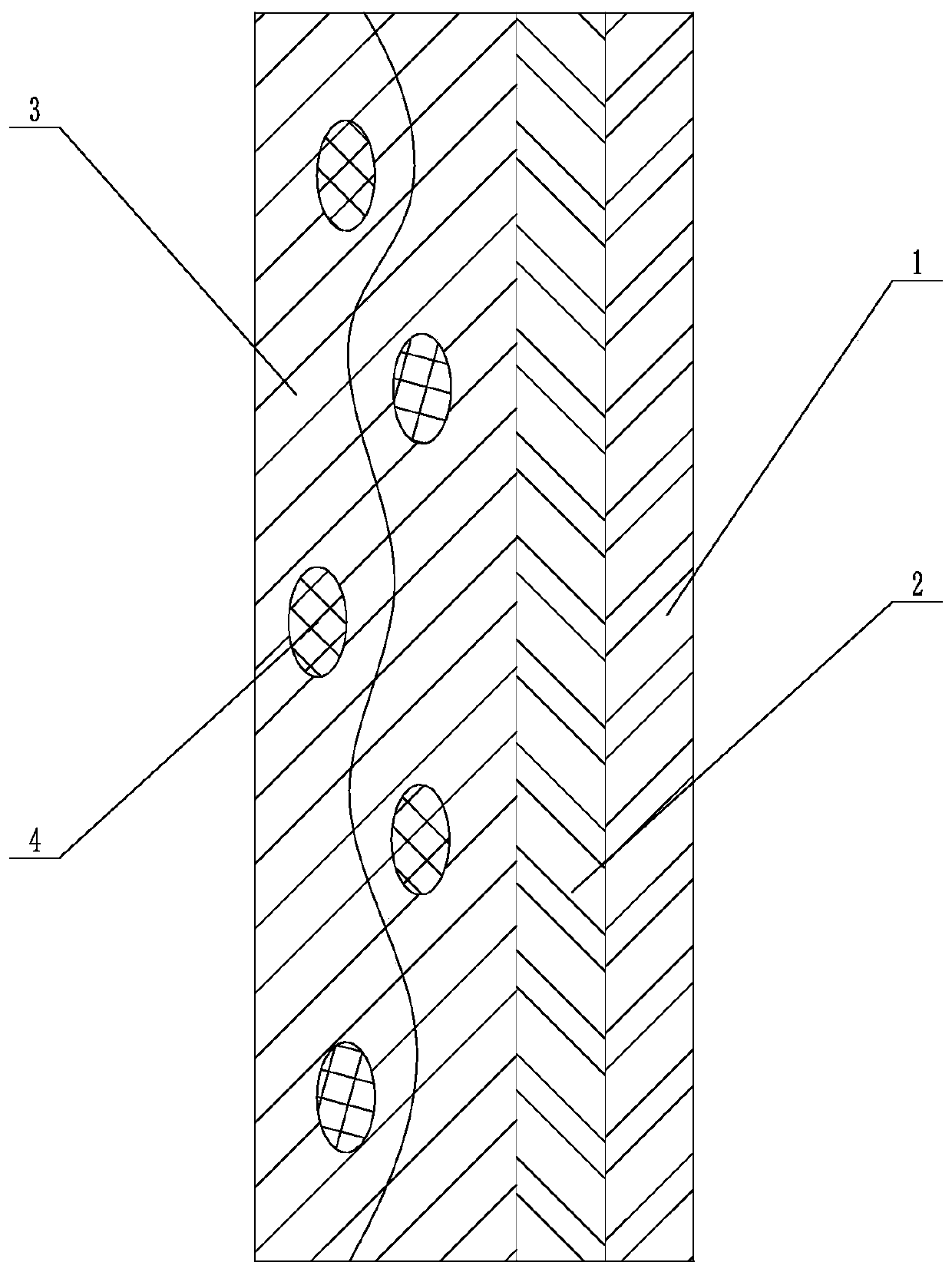

[0037] Take the perfluorosulfonic acid resin with IEC of 1.0mmol / g and the perfluorocarboxylic acid resin with IEC of 0.9mmol / g and the above-mentioned blended resins and compound them into perfluorinated ion exchange resin base membrane by melt co-extrusion casting Precursor, wherein the thickness of perfluorosulfonic acid layer (fluoropolymer layer 3 with sulfonic acid type functional groups) i...

Embodiment 2

[0050] Choose IEC as perfluorosulfonic acid resin (CF) of 1.1mmol / g 2 = CFOCF 2 CF(CF 3 )OCF 2 CF 2 SO 2 A binary copolymer of F and tetrafluoroethylene) and a perfluorocarboxylic acid resin with an IEC of 0.9 mmol / g (CF 2 = CFOCF 2 CF(CF 3 )OCF 2 CF 2 COOCH 3 and tetrafluoroethylene binary copolymers) at a mass ratio of 1:5 at a temperature of 270°C for blending and granulation to obtain a fully mixed resin with an exchange capacity of 0.93mmol / g, in which the sulfonic acid functional group and carboxylic acid The functional group molar ratio is 1:4.

[0051] Get the above-mentioned perfluorosulfonic acid resin and perfluorocarboxylic acid resin and the above-mentioned blended resin to be compounded into the precursor of the perfluoroion exchange resin base membrane by means of melt co-extrusion casting, wherein the perfluorosulfonic acid layer (with sulfonic acid The fluoropolymer layer 3) with acid type functional groups is 90 microns thick, the transition layer ...

Embodiment 3

[0057] Choose IEC as perfluorosulfonic acid resin (tetrafluoroethylene and CF) of 1.3mmol / g 2 = CFOCF 2 CF 2 SO 2 F binary copolymer) and perfluorocarboxylic acid resin (tetrafluoroethylene and CF 2 = CFOCF 2 CF(CF 3 )OCF 2 CF 2 COOCH 3 The binary copolymer) is blended and granulated at a temperature of 265 °C at a mass ratio of 5:5 to obtain a fully mixed resin whose exchange capacity is 1.1 mmol / g, wherein the molar ratio of sulfonic acid functional group to carboxylic acid functional group is 13:9.

[0058] Choose IEC as perfluorosulfonic acid resin (CF) of 1.1mmol / g 2 = CFOCF 2 CF(CF 3 )OCF 2 CF 2 SO 2 A binary copolymer of F and tetrafluoroethylene) and a perfluorocarboxylic acid resin with an IEC of 0.9 mmol / g (CF 2 = CFOCF 2 CF(CF 3 )OCF 2 CF 2 COOCH 3 and the binary copolymer of tetrafluoroethylene) and the blend obtained above are compounded into the precursor of the perfluoroion exchange resin base membrane by means of melt co-extrusion casting, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com