Processing technology for aluminum alloy battery tray of passenger car

A technology of battery tray and processing technology, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of heavy weight and unfavorable weight reduction of the whole vehicle, so as to reduce metal elastic deformation, ensure basic consistency, and improve resistance The effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

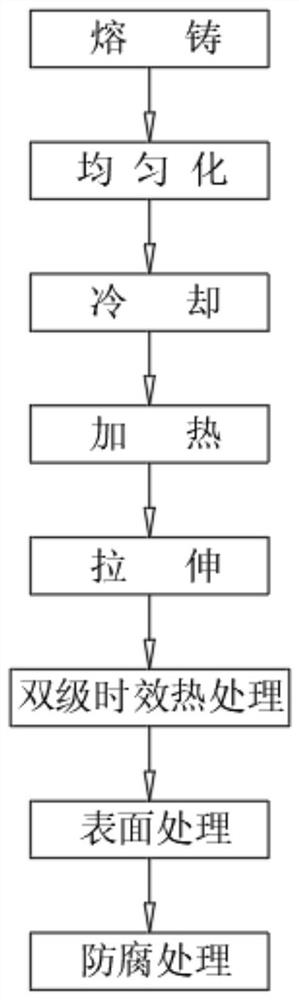

[0032] See figure 1 The present invention provides the following technical solution: a passenger car aluminum alloy battery tray, which is compared by the material ratio of the following mass fraction, the mass content of each of the alloying elements in the raw material is: Si1.12%, Mg0.75%. , Cu0.13%, Fe0.22%, MN0.66%, CR0.07%, Zn0.01%, Ti0.02%, Ca + Na / ≤ 0.002%, and the margin is A.

[0033] A passenger car aluminum alloy battery tray processing process, including the following steps:

[0034] S1, melting: the mixed raw material is added to the smelting furnace by the process, and the melt is effectively removed by demented, the slag refining means, the gas is effectively removed, and the melting aluminum liquid is cooled by the deep well casting system. Casting causes aluminum alloy ingots;

[0035] S2, homogenization: Place the aluminum alloy ingot at 580 ° C for high temperature homogenization treatment, heating for 9 h;

[0036] S3, cooling: cooling with strong water, coo...

Embodiment 2

[0050] See figure 1 The present invention provides the following technical solution: a passenger car aluminum alloy battery tray, which is compared by the material ratio of the material, and the mass content of each alloy element in the raw material is: Si1.15%, Mg0.78%. Cu0.15%, Fe0.25%, MN0.7%, CR0.08%, Zn0.02%, Ti0.04%, Ca + Na / ≤ 0.002%, and the margin is A.

[0051] A passenger car aluminum alloy battery tray processing process, including the following steps:

[0052] S1, melting: the mixed raw material is added to the smelting furnace by the process, and the melt is effectively removed by demented, the slag refining means, the gas is effectively removed, and the melting aluminum liquid is cooled by the deep well casting system. Casting causes aluminum alloy ingots;

[0053] S2, homogenization: Place the aluminum alloy ingot at 583 ° C for high temperature homogenization treatment, heating 10 h;

[0054] S3, cooling: cooling with strong water, cooling it to 113 ° C;

[0055]...

Embodiment 3

[0068] See figure 1 The present invention provides the following technical solution: a passenger car aluminum alloy battery tray, which is compared by the following mass fraction, the mass percentage of alloying elements in the raw material is: Si1.20%, MG0.80%. Cu0.180%, FE0.270%, MN0.80%, CR0.09%, Zn0.03%, Ti0.05%, Ca + Na / ≤ 0.002%, and the margin is A.

[0069] A passenger car aluminum alloy battery tray processing process, including the following steps:

[0070] S1, melting: the mixed raw material is added to the smelting furnace by the process, and the melt is effectively removed by demented, the slag refining means, the gas is effectively removed, and the melting aluminum liquid is cooled by the deep well casting system. Casting causes aluminum alloy ingots;

[0071] S2, homogenization: Place the aluminum alloy ingot at 585 ° C for high temperature homogenization treatment, heating 11h;

[0072] S3, cooling: cooling with strong water, cooling it to 114 ° C;

[0073] S4, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com