Heating furnace, heating system and method for treating oily sludge by using heating furnace and heating system

A heating system and heating furnace technology, applied in chemical instruments and methods, mining wastewater treatment, water/sludge/sewage treatment, etc., can solve the problems of substandard oil sludge treatment, uneven temperature field, slow heat transfer speed, etc. , to avoid uneven heat conduction, efficient and stable processing, and improve heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

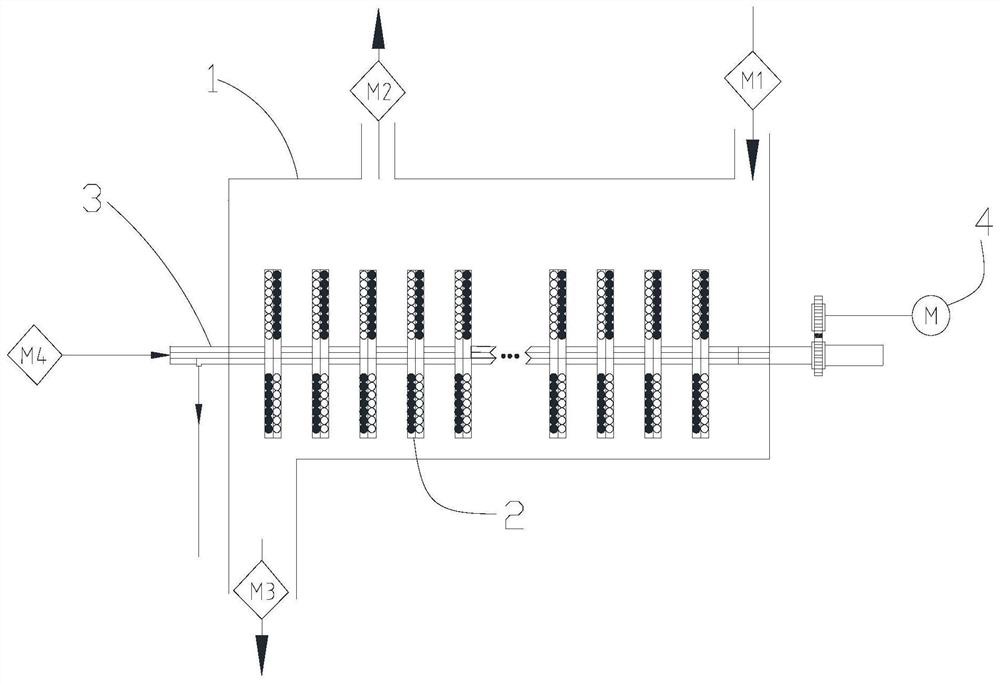

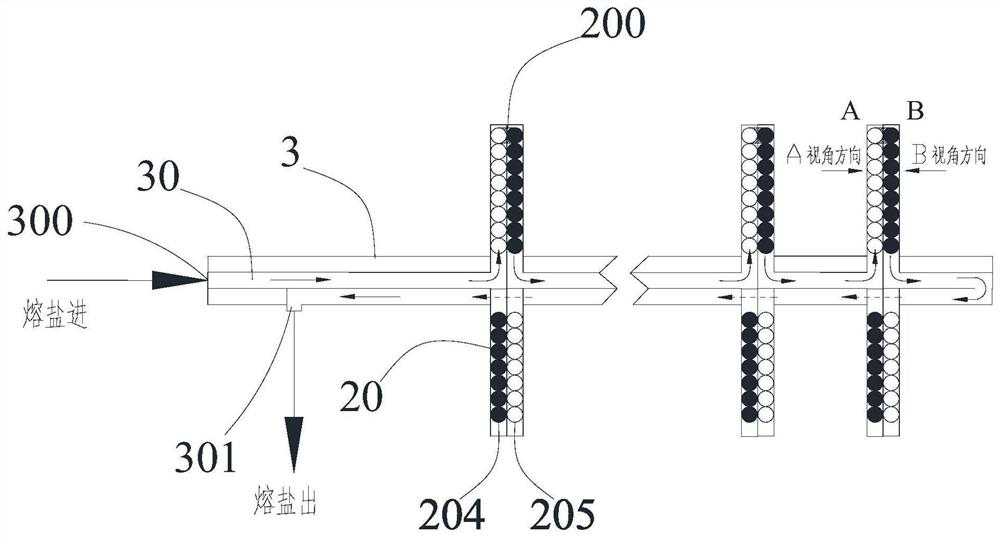

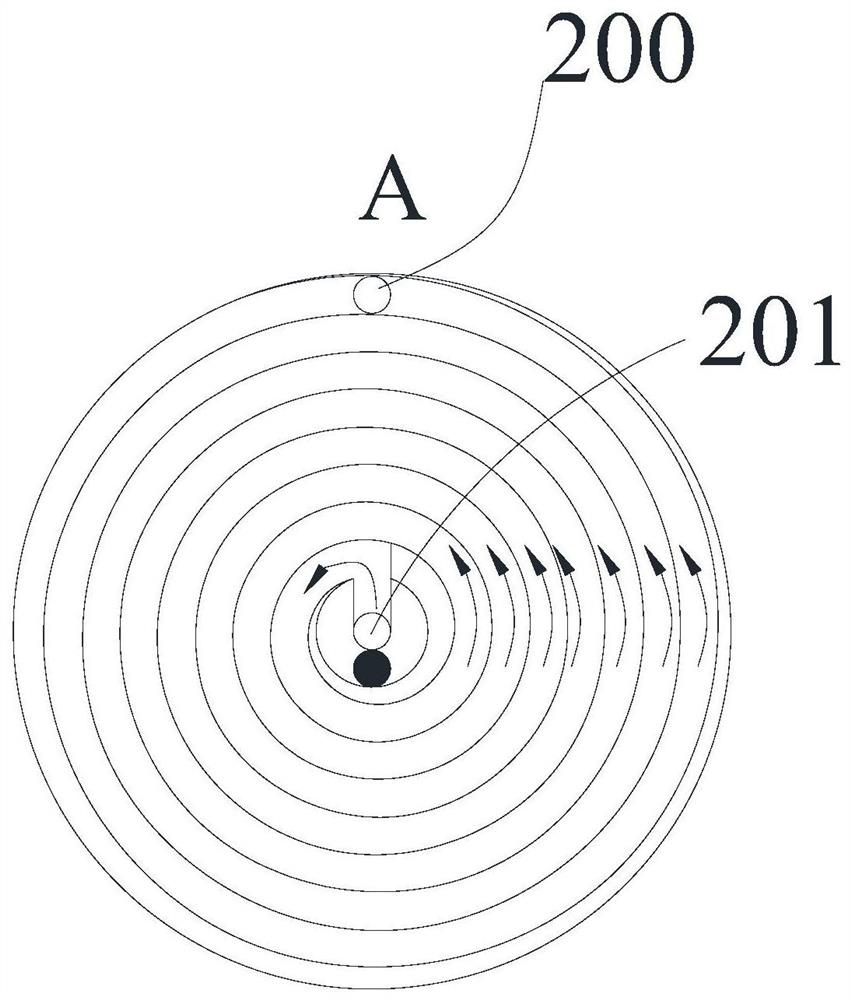

[0072] Such as figure 1 As shown, this embodiment provides a heating furnace, including a furnace body 1, a heating turntable 2 and a rotating shaft 3; the heating turntable 2 is arranged in the furnace body 1, and the rotating shaft 3 runs through the furnace body 1; The connection is used to drive the heating turntable 2 to rotate, and one end of the rotating shaft 3 is connected with the motor 4 through a gear set. Such as figure 2 , image 3 and Figure 4 As shown, the heating turntable 2 is provided with a medium channel 20 for inputting and outputting heating medium. In order to further improve the heating uniformity and thermal efficiency, the medium channel 20 is set in the form of a coil; in order to improve the utilization rate of heat, the medium channel 20 is provided with two layers of coils in each heating turntable 2, between the two layers of coils Connected through the connecting pipe 200; the rotating shaft 3 is provided with a hollow pipeline 30, and th...

Embodiment 2

[0086] Such as Figure 6 As shown, this embodiment provides a heating furnace, including a furnace body 1, a heating turntable 2 and a rotating shaft 3; the heating turntable 2 is arranged in the furnace body 1, and the rotating shaft 3 runs through the furnace body 1; The connection is used to drive the heating turntable 2 to rotate, and one end of the rotating shaft 3 is connected with the motor 4 through a gear set.

[0087] Such as Figure 6 and Figure 7 As shown, different from Embodiment 1, the heating turntable 2 is divided into two independent parts, the first heating turntable part 2-a and the second heating turntable part 2-b; the hollow pipeline 30 is divided into two independent parts part, the first hollow piping unit 30-a and the second hollow piping unit 30-b. The first heating turntable part 2-a cooperates with the first hollow pipeline unit 30-a to form a molten salt circulation channel, and the second heating turntable part 2-b cooperates with the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com