Gas-solid separating method and system for simple substance sulphur in sulphur-containing exhaust

A technology of gas-solid separation and elemental sulfur, applied in the field of environmental pollution control, can solve the problems of waste of sulfur resources, secondary pollution, etc., and achieve the effects of reducing desulfurization costs, efficiency, energy saving and environmental protection, and stable and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

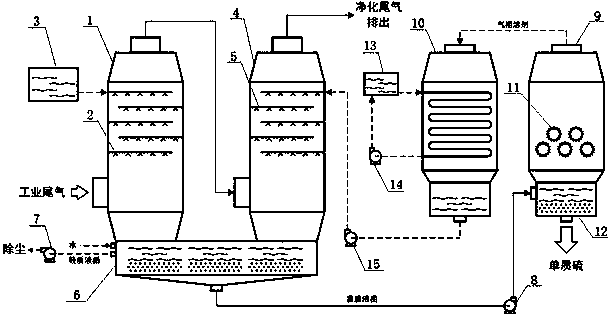

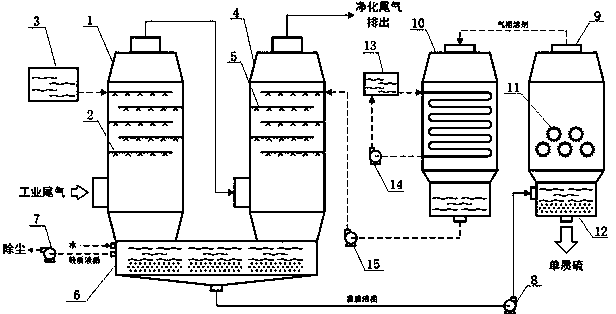

[0039]A gas-solid separation method for elemental sulfur in sulfur-containing tail gas, comprising the following steps:

[0040] S1. Rapidly cool down the sulfur-containing tail gas to below 25°C, so that the elemental sulfur vapor in the sulfur-containing tail gas condenses into elemental sulfur solid particles, and the elemental sulfur solid particles and dust particles settle to the extraction tank;

[0041] S2. Carry out low-temperature washing to the tail gas, the washing liquid is a low-temperature heavy liquid phase solvent, the tail gas after washing is discharged, and the washed liquid flows into the extraction tank, the dust is dissolved in the light liquid phase in the extraction tank, and the light liquid is discharged. Elemental sulfur particles are dissolved in the heavy liquid phase in the extraction tank;

[0042] S3, pumping out the heavy liquid, heating it to 90°C by irradiation, collecting elemental sulfur particles, and evaporating at the same time to produ...

Embodiment 2

[0045] A gas-solid separation method for elemental sulfur in sulfur-containing tail gas, comprising the following steps:

[0046] S1. Rapidly cool down the sulfur-containing tail gas to below 20°C, so that the elemental sulfur vapor in the sulfur-containing tail gas condenses into elemental sulfur solid particles, and the elemental sulfur solid particles and dust particles settle to the extraction tank;

[0047] S2. Carry out low-temperature washing to the tail gas, the washing liquid is a low-temperature heavy liquid phase solvent, the tail gas after washing is discharged, and the washed liquid flows into the extraction tank, the dust is dissolved in the light liquid phase in the extraction tank, and the light liquid is discharged. Elemental sulfur particles are dissolved in the heavy liquid phase in the extraction tank;

[0048] S3, pumping out the heavy liquid, heating it to 70°C by irradiation, collecting elemental sulfur particles, and evaporating at the same time to prod...

Embodiment 3

[0051] A gas-solid separation method for elemental sulfur in sulfur-containing tail gas, comprising the following steps:

[0052] S1. Rapidly cool down the sulfur-containing tail gas to below 10°C, so that the elemental sulfur vapor in the sulfur-containing tail gas condenses into elemental sulfur solid particles, and the elemental sulfur solid particles and dust particles settle to the extraction tank;

[0053] S2. Carry out low-temperature washing to the tail gas, the washing liquid is a low-temperature heavy liquid phase solvent, the tail gas after washing is discharged, and the washed liquid flows into the extraction tank, the dust is dissolved in the light liquid phase in the extraction tank, and the light liquid is discharged. Elemental sulfur particles are dissolved in the heavy liquid phase in the extraction tank;

[0054] S3, pumping out the heavy liquid, heating it to 50°C by irradiation, collecting elemental sulfur particles, and evaporating at the same time to prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com