Treatment system and process for treating oil dirt at bottom of cabin by using bionic gills

A treatment system, bionic fish technology, applied in the direction of biological water/sewage treatment, filtration treatment, petroleum industry, etc., can solve the problems that the sewage treatment system is not suitable for shipboard use, the leakage of transport bilge water, and the lack of emulsified oil, etc., to achieve Low cost, improved treatment effect, wide source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

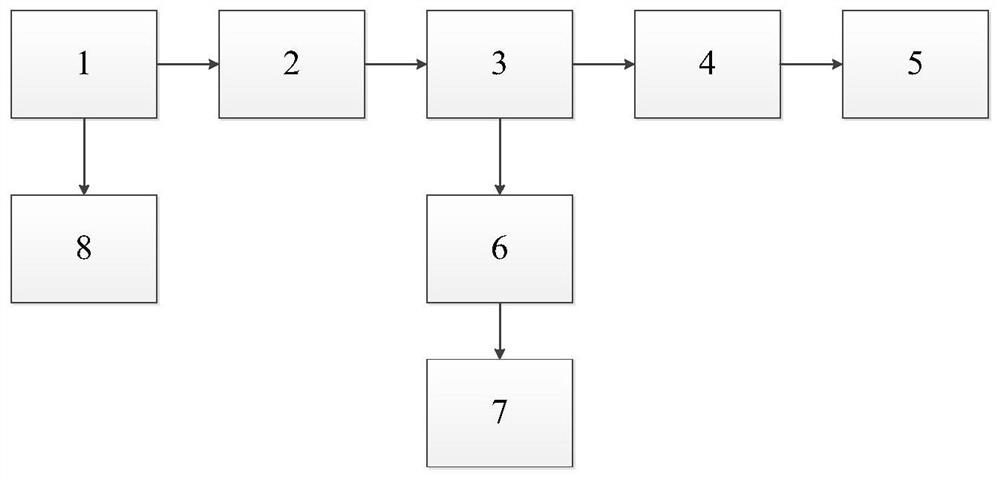

[0046] A treatment system that uses bionic fish gills to treat oil pollution at the bottom of the cabin. The system includes an adsorption tank, a regulating tank, a degradation tank, an exhaust system and a storage tank. The adsorption tank, the regulating tank, the degradation tank, the storage tank and the cooling water There is a grille between the systems to block. Adjust pH to 4, COD to 1000mg / L, petroleum hydrocarbon content to 1000ppm, BOD to 1000mg / L, heavy metal ions (Cu 2+ 、Cr 4+ , Pb 2+ , Mn 4+ etc.) oily sewage with a content of 150mg / L is introduced into the system for comprehensive treatment.

[0047] Control the mass-to-liquid ratio of modified straw and oily sewage in the adsorption tank to 1:3, settling time in the regulating tank to 48 hours, adjust the pH to 7, put the polyacrylamide flocculant into the mass-to-liquid ratio to 1:3, and the degradation tank to the bacteria-to-liquid ratio to 1 :400, the microbial degradation time is 24h, and the flow rat...

Embodiment 2

[0054] Control the mass-to-liquid ratio of modified straw and oily sewage in the adsorption tank to 1:7, settling time in the regulating tank to 12 hours, do not adjust the pH, put the polyacrylamide flocculant into the mass-to-liquid ratio to 1:10, and the degradation tank to the bacteria-to-liquid ratio to 1: 100, the microbial degradation time is 10h, and the flow rate of oily sewage is 1m / s.

[0055] Under this condition, the relevant water quality indicators were tested for the oily sewage in the process of system treatment and after treatment, and a conclusion was drawn:

[0056] (1) Sampling the oily sewage passing through the adsorption tank found that the petroleum hydrocarbon content of the oily sewage dropped to 460ppm, the heavy metal ion content dropped to 25.13mg / L, the COD dropped to 560.47mg / L, and the BOD dropped to 470.29mg / L.

[0057] (2) After sampling the oily sewage passing through the adjustment tank, it was found that the heavy metal ion content of the ...

Embodiment 3

[0061] Compared with the previous two examples, the pH of the oily sewage in Example 3 was adjusted to 9, and other parameters remained unchanged.

[0062] Control the mass-to-liquid ratio of modified straw and oily sewage in the adsorption tank to 1:5, settling time in the regulating tank to 12 hours, do not adjust the pH, put the polyacrylamide flocculant into the mass-to-liquid ratio to 1:8, and the degradation tank to the bacteria-to-liquid ratio to 1: 200, the microbial degradation time is 18h, and the flow rate of oily sewage is 1m / s.

[0063] Under this condition, the relevant water quality indicators were tested for the oily sewage in the process of system treatment and after treatment, and a conclusion was drawn:

[0064] (1) Sampling the oily sewage passing through the adsorption tank found that the petroleum hydrocarbon content of the oily sewage dropped to 391ppm, the heavy metal ion content dropped to 18.29mg / L, the COD dropped to 503.62mg / L, and the BOD dropped t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com