Loess layer-based dry drilling tunneling method and equipment

A loess layer, dry drilling technology, applied in drilling equipment, drilling equipment and methods, earthwork drilling and mining, etc., can solve the problems of cuttings difficult to take out of the ground, recurring leakage, prone to downhole accidents, etc., to avoid environmental pollution Accidents, the effect of solving leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

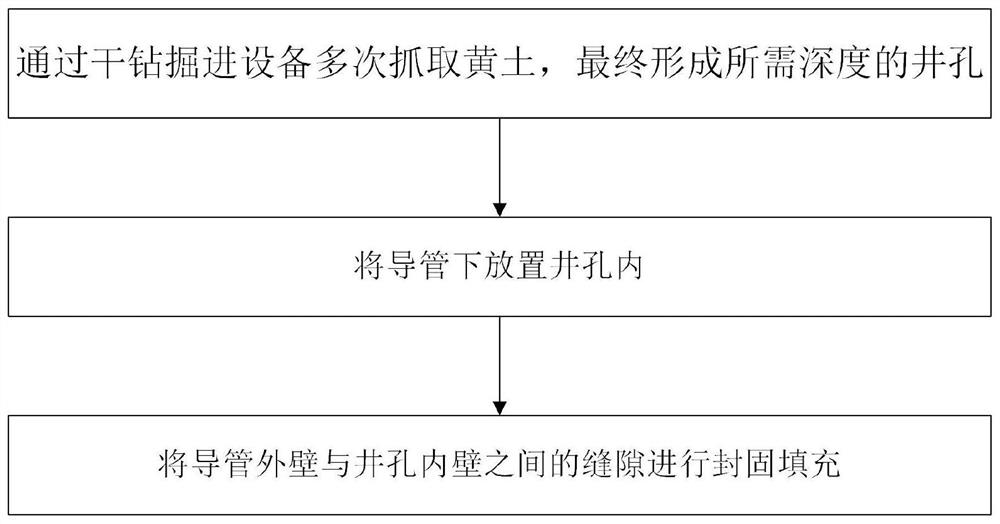

[0053] refer to figure 1 , is a schematic diagram of the dry drilling and excavation steps based on the loess layer of the present invention, a dry drilling and excavation method based on the loess layer, comprising the following steps

[0054] Step 1: Dry Drilling

[0055] Dry drilling is carried out by dry drilling equipment to form a wellbore of required depth;

[0056] Step 2: down the catheter

[0057] Place the catheter down the wellbore;

[0058] Step 3: Seal the inner and outer rings

[0059] Seal and fill the gap between the outer wall of the conduit and the inner wall of the wellbore.

[0060] The above-mentioned implementation is based on a drilling method that does not require fluid medium circulation in the drilling construction of the loess layer, because the loess layer is a special stratum structure, wherein the stratum structure is loose and has natural fractures on the surface of the loess layer, and at the same time There will also be stratum structures...

Embodiment 2

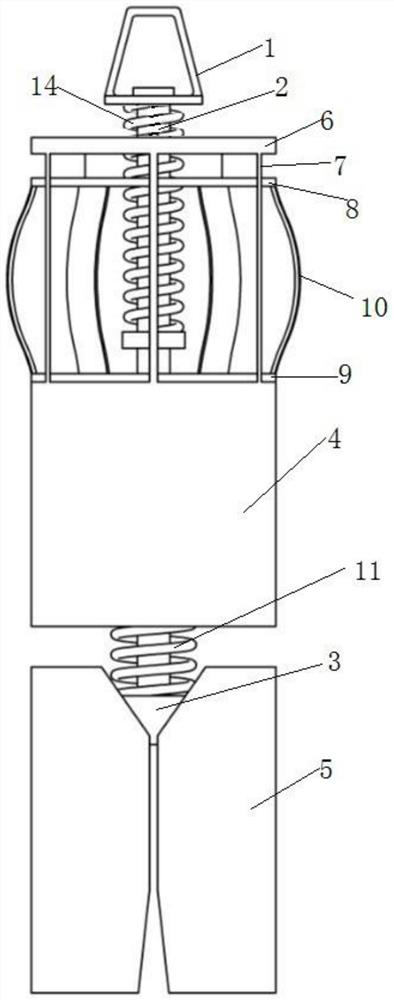

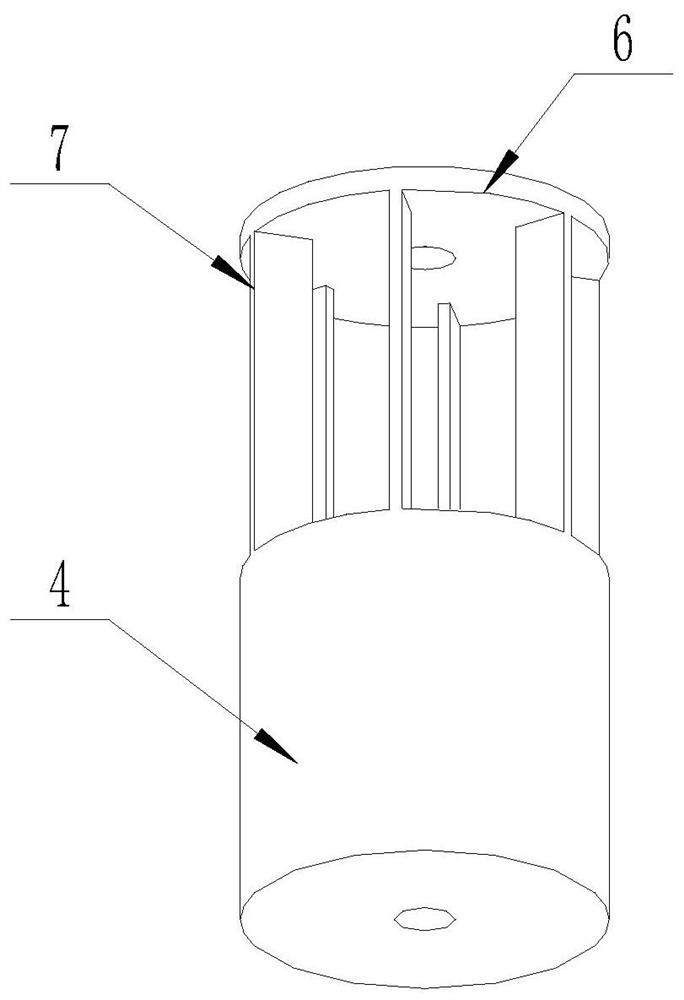

[0063] In the further described step one, the specific construction method of dry drilling and excavation includes

[0064] First install the digging device in the dry drilling equipment directly above the well hole to be drilled;

[0065] Adjust the center position of the digging device to correspond to the center position of the borehole to be drilled;

[0066] The driving device in the dry drilling excavation equipment is started, and the excavating device is driven by the driving device to carry out dry drilling and excavation.

[0067] Further, the dry drilling excavation is that the excavating device is started by the driving device and then freely falls downwards by its own weight, rushes to the ground and penetrates into the soil layer through the downward free fall movement, and then grabs the loess.

[0068] Further, after grabbing the loess, the driving device drives the digging device to move upwards. After moving out of the well hole, the digging device is locate...

Embodiment 3

[0071] Further, in step 2, the conduit is lowered into the wellbore and a hanging device is used to hang the conduit into the wellbore excavated by dry drilling.

[0072] Further, before using the hanging device to hang the conduit into the well hole that is driven in and out by dry drilling, there is also a conduit stopper bracket at the well hole, and the inner diameter of the conduit stopper bracket is larger than the diameter of the wellbore.

[0073] When the conduit is suspended, a gap of 300 mm to 500 mm is preferably left between the bottom of the conduit and the bottom of the well.

[0074] The conduit adopts PE400 corrugated drainage pipe.

[0075] In this embodiment, when the pipe is lowered, it is necessary to use a hanging device to hang the pipe into the well hole through the dry drilling. There is a sling on the top, and the sling on the hanging device is connected to the clamp and the rope tightener. Specifically, the tube is clamped by the clamp connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com