Waste glass crushing and sorting recycling system and method

A technology for waste glass and glass breaking, applied in glass recycling, solid separation, waste treatment, etc., can solve the problems of single recycling technology, secondary pollution, and not considering the sorting and sorting of different color glass, and achieve high sorting efficiency. , Environmentally friendly, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An embodiment of the waste glass crushing, sorting, and recycling system of the present invention, the waste glass crushing, sorting, and resource recycling system described in this embodiment includes a glass crushing device, a magnetic separation device, an eddy current separation device, a grinding device, and a wind separation device. selection device and photoelectric separation device; the glass crushing device, magnetic separation device, eddy current separation device, grinding device, wind separation device and photoelectric separation device are connected in sequence; the glass crushing device is a hammer crushing device; Both the glass breaking device and the grinding device are equipped with a circulating water cooling system; the circulating water cooling system controls the temperature in the glass breaking device and grinding device to be lower than 100°C. The glass crushing device and the grinding device are provided with a sound insulation cover, and the...

Embodiment 2

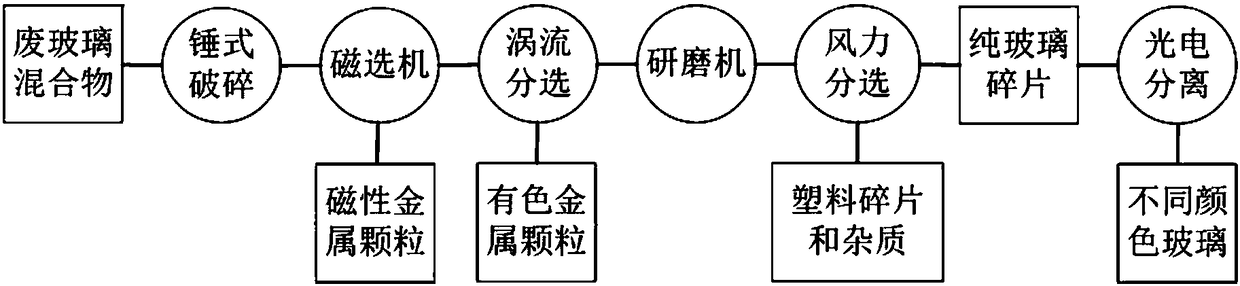

[0031] An embodiment of the waste glass crushing, sorting and recycling method of the present invention is shown in the attached figure 1 shown, including the following steps:

[0032] (1), crushing: the waste glass mixture is subjected to hammer crushing to obtain a crushed mixture;

[0033] (2), magnetic separation: the magnetic metal particles in the broken mixture are removed by magnetic separation through a magnetic separator to obtain the broken mixture after removing the magnetic metal;

[0034] (3), eddy current separation: remove the non-ferrous metal particles from the crushed mixture after removing the magnetic metal by eddy current separation, and obtain the crushed mixture after removing the non-ferrous metal particles;

[0035] (4) Removal of impurities: grind the crushed mixture after removing non-ferrous metal particles with a grinder, and then use wind separation to remove plastic particles and attachment impurity particles in the ground mixture to obtain cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com