High-temperature steel slag carbonation deep stabilization treatment device and method

A technology of carbonization depth and treatment device, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of steel slag stability that cannot be completely solved, lack of steel slag deep stabilization process technology and equipment, and cannot be used. Concrete and other problems, to achieve the effect of improving the value of resource utilization, significant economic and social benefits, and short treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

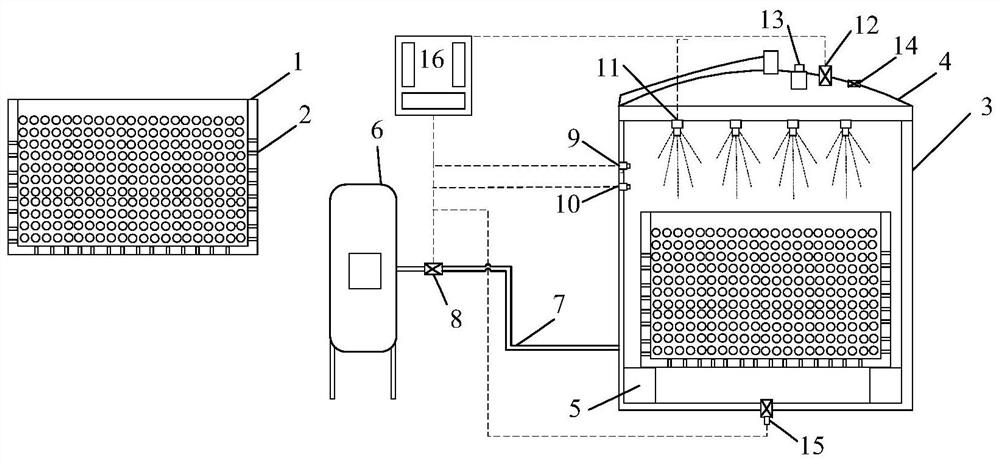

[0028] A high-temperature steel slag carbonization depth stabilization treatment device such as figure 1 As shown, a high-temperature steel slag carbonization depth stabilization treatment device includes: steel slag tank 1, air hole 2, stabilization tank 3, tank door 4, tank seat 5, gas tank 6, air pipe 7, vent valve 8, pressure gauge 9 , thermometer 10, water spray port 11, exhaust valve 12, safety valve 13, explosion-proof valve 14, drain valve 15, central control system 16. The steel slag tank 1 is placed on the tank seat 5 at the bottom of the stabilizer tank 3; the tank body of the steel slag tank 1 is provided with an air hole 2; the gas tank 6 is connected to the stabilizer tank 3 through a gas pipe 7, and is used to dissipate the CO in the gas tank 6 2 The gas enters from the bottom of the stabilizer tank 3; the tank door 4 is set on the upper part of the opening of the stabilizer tank 3 for closing the stabilizer tank 3; Fetching water; exhaust valve 12, safety valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com