Clean preparation method of high-quality and high-purity natural-color bamboo fluff pulp

A high-purity, high-quality technology, applied in chemical/chemomechanical pulp, washing/replacement pulp treatment liquid, papermaking, etc., can solve the problems of increasing the amount of chemicals in the bleaching section, affecting the product qualification rate, and increasing costs, and achieves alleviation The effect of raw material cost pressure, improving resource utilization value, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

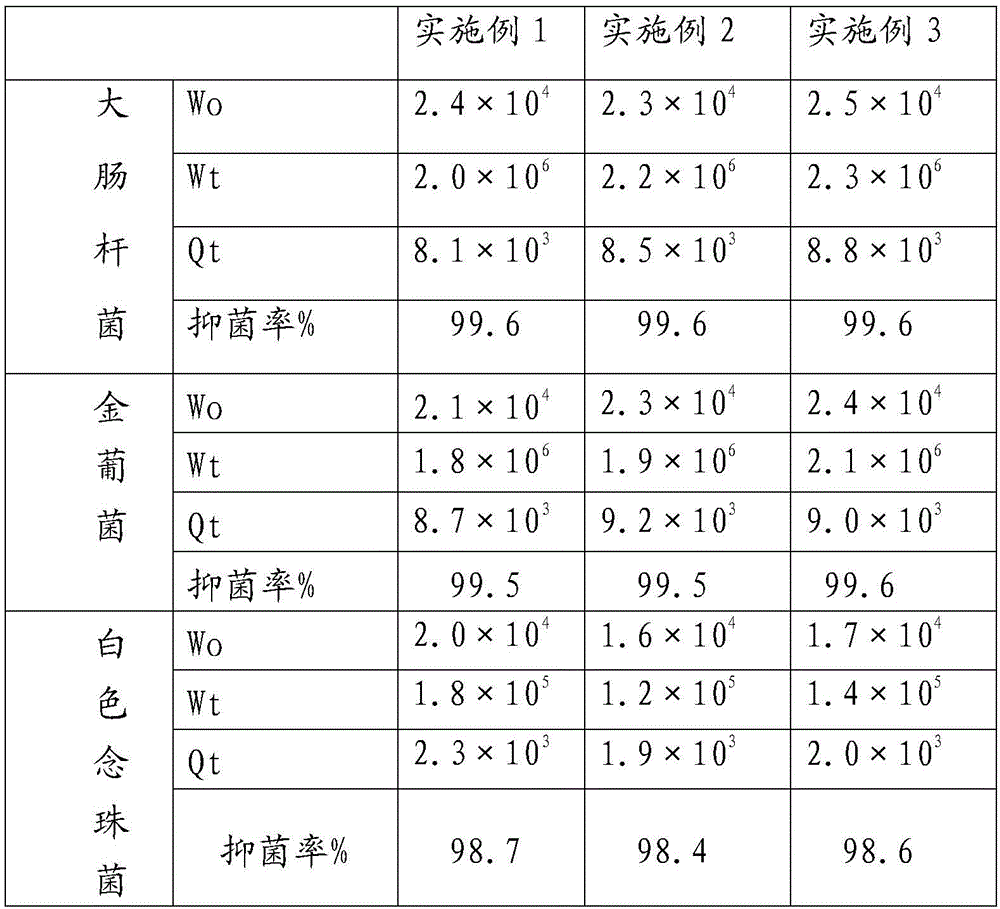

Examples

Embodiment 1

[0034] (1) fully and evenly disperse the commercially available natural color KP bamboo slurry;

[0035] The intermittent medium-concentration hydraulic disintegrator with a milder disintegration effect is adopted. The disintegration effect mainly depends on the pumping action generated by the conical screw moving the pulp, and the disintegration effect is excellent. The bamboo pulp board is disintegrated and dispersed into a uniform fiber suspension. Here The used intermittent medium-consistency hydraulic disintegrator has a medium-concentration crushed pulp concentration of 7%-12%, does not need to be heated for crushing, and the crushing temperature is room temperature. The specific operation is to send the bamboo pulp board to be decomposed into the pulper with a certain water storage capacity through the weighing conveyor, so as to accurately control the decomposed pulp concentration.

[0036] The mass content of α-cellulose in commercially available natural color KP bamb...

Embodiment 2

[0049] Other content is as embodiment 1, comprises the following steps in preparation process:

[0050] (1) fully and evenly disperse the commercially available natural color KP bamboo slurry;

[0051] (2) After the thawed slurry is diluted, it is sent to a heat disperser, and sodium hydroxide is added to carry out alkali extraction while dispersing.

[0052] The heat dispersion time is 15 minutes, the temperature is 60°C, the mass concentration of the incoming pulp is 3%, the mass concentration of the outgoing pulp is 15%, and the amount of sodium hydroxide is 3.5% relative to the dry pulp mass.

[0053] (3) The slurry after thermal dispersion is diluted with water, and then enters the flotation machine for flotation, and at the same time, the collector agent alkylphenol polyoxyethylene ether is added.

[0054] Flotation process conditions: slurry mass concentration 1.5%, temperature at room temperature, time 8min, relative to the dry pulp mass, the amount of ethylene oxide ...

Embodiment 3

[0061] Other content is as embodiment 1, comprises the following steps in preparation process:

[0062] (1) fully and evenly disperse the commercially available natural color KP bamboo slurry;

[0063] (2) After the thawed slurry is diluted, it is sent to a heat disperser, and sodium hydroxide is added to carry out alkali extraction while dispersing.

[0064] The heat dispersion time is 12 minutes, the temperature is 80°C, the mass concentration of the incoming pulp is 7%, the mass concentration of the outgoing pulp is 10%, and the amount of sodium hydroxide is 0.5% relative to the dry pulp mass.

[0065] (3) The slurry after thermal dispersion is diluted with water, and then enters the flotation machine for flotation, and at the same time, the collector fatty alcohol polyoxyethylene ether is added.

[0066] The technological conditions of flotation: the mass concentration of the slurry is 1.2%, the temperature is room temperature, the time is 15 minutes, and the amount of et...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com