Method and device for preparing carbon material by heating molten salt and pyrolyzing biomass through solar energy

A biomass and solar technology, applied in lighting and heating equipment, waste heat treatment, carbon preparation/purification, etc., can solve problems such as difficult to achieve mass production, high energy consumption, and inability to continuously produce carbon, so as to improve the efficiency of carbon production , Ensure the safety of the pipeline and shorten the carbon production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

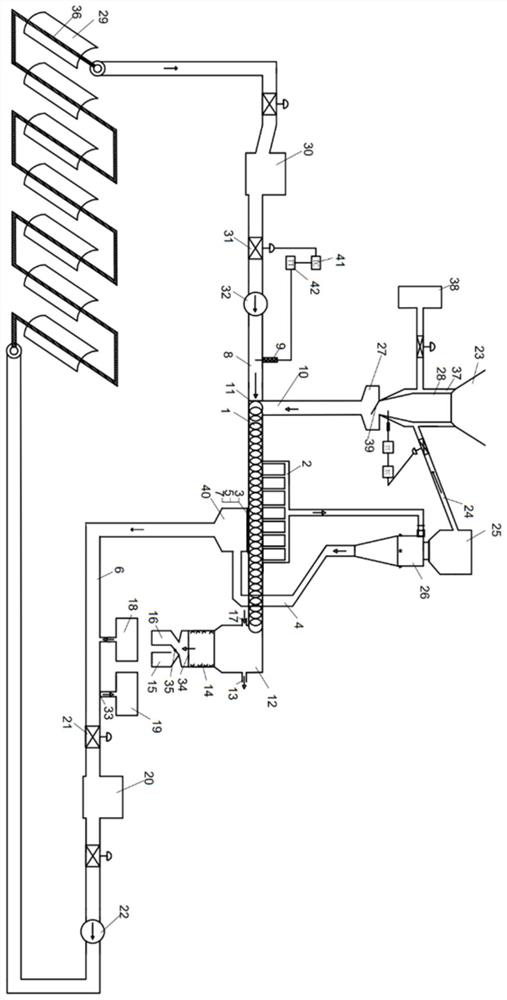

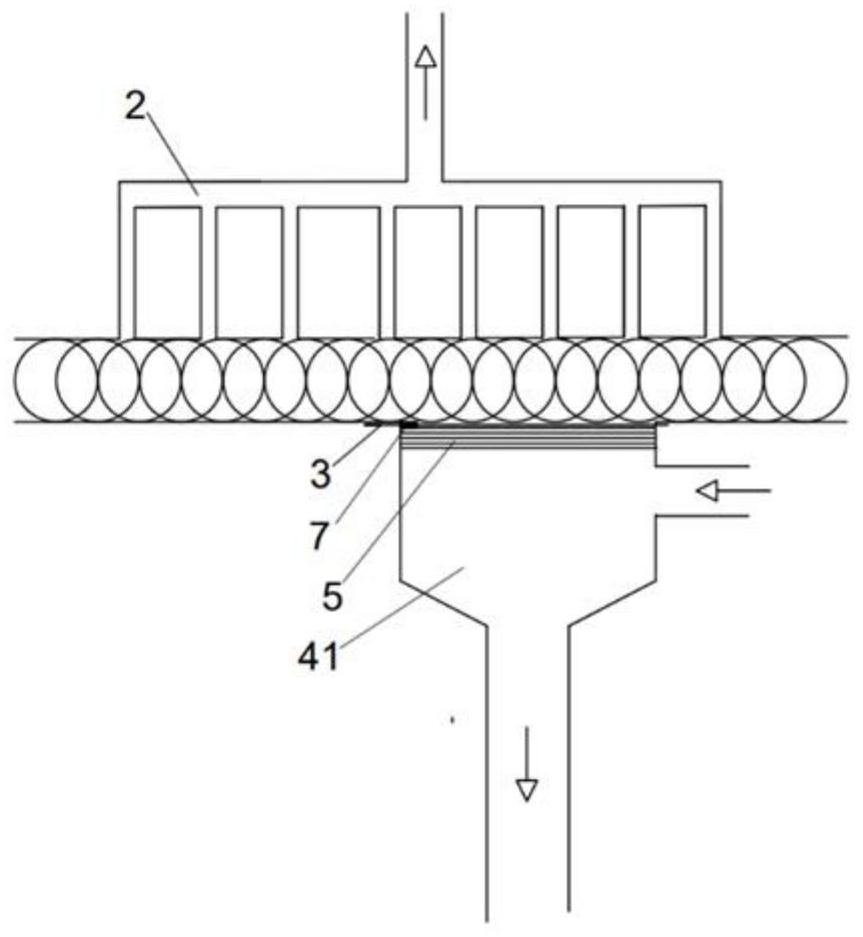

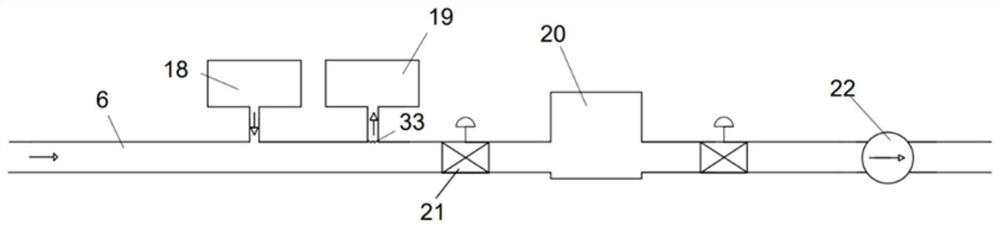

[0038] like Figure 1 to Figure 6 As shown in the figure, the present invention discloses a method and device for solar heating molten salt pyrolysis biomass carbon material. Collecting heat gas drying mechanism, filtering mechanism, mixing propelling mechanism, molten salt impurity removal mechanism, rare gas cooling mechanism, PLC controller and cleaning and separating high value-added carbon mechanism; It is connected with one end of the hot molten salt pipeline 8, and the cold molten salt pipeline 6 and the other end of the hot molten salt pipeline 8 are connected through the mixing propulsion mechanism, and the output end of the hybrid propulsion mechanism is provided with the A rare gas cooling mechanism, the cleaning and separating high value-added carbon mechanism is arranged below the rare gas cooling mechanism, the cold molten salt pipeline 6 is provided with a cold molten salt storage bin 20, and the cold molten salt pipeline 6 is provided with a cold molten salt st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com