Method for synergistically treating heavy metal sludge

A heavy metal sludge and co-processing technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve high equipment investment or operating costs, high energy consumption in the utilization process, and heavy metal recovery rate Low-level problems, to achieve the effect of complete detoxification, low investment and operating costs, and large amount of sludge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The heavy metal sludge comes from the cold rolling wastewater treatment station of a stainless steel enterprise. It is a by-product of the lime milk-chemical precipitation process to treat cold rolling wastewater (referred to as cold rolling sludge). After the cold rolling sludge is filtered by plate and frame, it is stored in In a warehouse with anti-seepage base and good ventilation, the typical chemical components of the sludge are: Cr(3.0%), Ni(0.7%), Zn(0.02%), Pb(0.03%), Fe(22.4%), Si (3.1%), K (0.03%), Na (0.01%), total carbon (2.0%), burning loss (15%), CaSO4 (22%), CaF2 (18%), CaCl2 (2%), heavy metal The sludge has fine particles, complex components, high leaching toxicity, and is classified as hazardous waste (National Hazardous Waste List HW17 and HW21). According to environmental protection requirements, it needs to be properly disposed of by outsourced qualified enterprises.

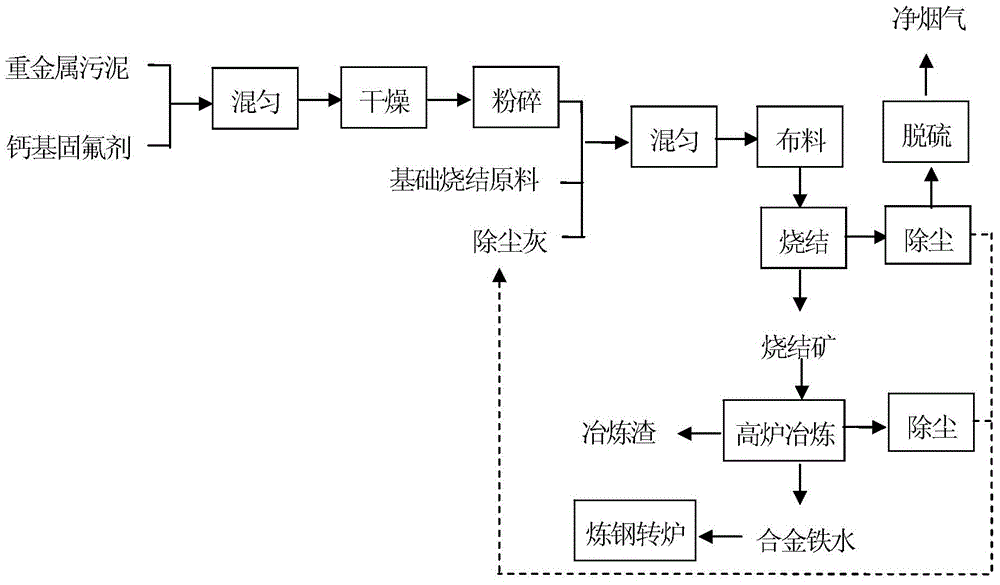

[0040] Such as figure 1 As shown, when 1,000 tons of cold rolling sludge is natu...

Embodiment 2

[0046] When 1,000 tons of stainless steel cold-rolling sludge is naturally dried to a moisture content of 45%, it is mixed with 200 tons of dolomite powder (calcium-based fluorine-fixing agent), dried, and crushed to obtain a moisture content of 15% and a particle size range of 1 to 5mm. Calcium-based sludge, in a one-month industrial test, calcium-based sludge and 15,000 tons of basic sintering raw materials (composed of 85 parts of concentrate powder, 5 parts of coal powder, 5 parts of dolomite powder and 5 parts of returned ore, of which The ore powder is composed of 15 parts of Carajas powder, 20 parts of CVRD powder, 5 parts of PB powder, 10 parts of Xie San mine, 3 parts of miscellaneous mine, 17 parts of Mac powder, 9 parts of Luobu River powder, and 31 parts of Yang Di powder) , 400 tons of dedusting ash (consisting of low-zinc dedusting ash from sintering waste gas dedusting device, blast furnace waste gas dedusting device and converter dedusting device in a certain pr...

Embodiment 3

[0051] When 1,000 tons of stainless steel cold rolling sludge is naturally dried to a moisture content of 35%, it is mixed with 250 tons of dolomite powder (calcium-based fluorine-fixing agent), dried, and crushed to obtain a moisture content of 18% and a particle size range of 0.5 to 5mm. Calcium-based sludge, in a one-month industrial test, calcium-based sludge and 18,000 tons of basic sintering raw materials (composed of 82 parts of concentrate powder, 8 parts of coal powder, 7 parts of dolomite powder and 3 parts of returned ore, of which The ore powder is composed of 10 parts of Carajas powder, 25 parts of CVRD powder, 15 parts of PB powder, 5 parts of Xie San mine, 5 parts of miscellaneous mine, 10 parts of Mac powder, 10 parts of Luobu River powder, and 20 parts of Yangdi powder) , 350 tons of dedusting ash (consisting of low-zinc dedusting ash from sintering waste gas dedusting device, blast furnace waste gas dedusting device and converter dedusting device in a certain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com