Method for resource recovery of construction wastes

A disposal method and technology of construction waste, applied in the direction of sustainable waste treatment, climate sustainability, solid waste management, etc., can solve the problem of low added value of resource utilization, and achieve the effect of increasing utilization value and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, construction waste resource disposal:

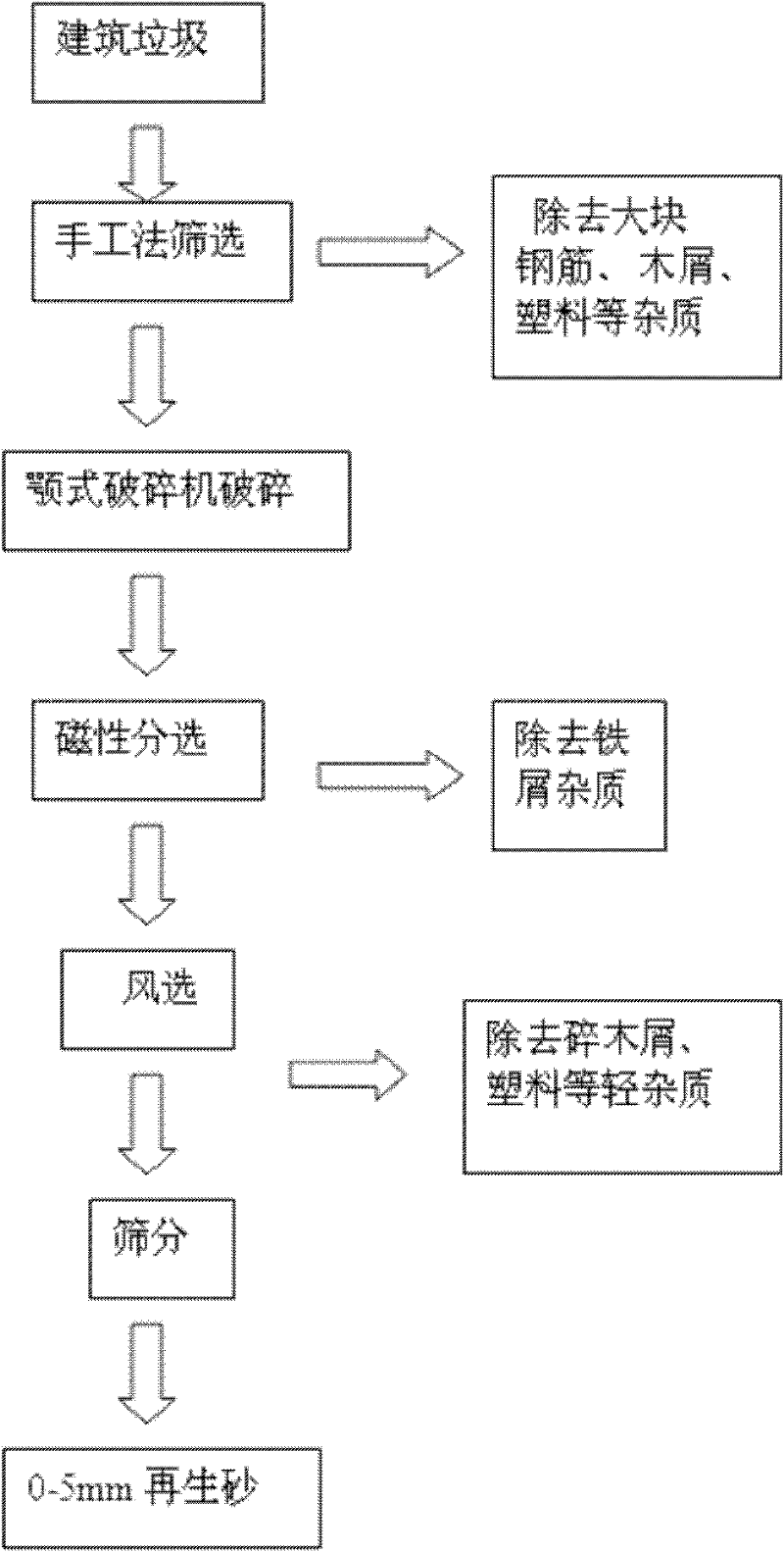

[0025] Firstly, reclaimed sand with a particle size of 0-5mm is prepared: the materials are manually screened to remove impurities such as large steel bars, wood and plastics that are easy to pick out; the manually screened materials are sent to the jaw crusher for crushing; The crushed material is sent to the magnetic separator for magnetic separation to remove iron filings; the magnetically separated material is sent to the winnowing machine for winnowing to remove light impurities such as broken wood and plastic; the winnowed The material is screened, and the material with a particle size greater than 5mm is screened out to obtain reclaimed sand with a particle size of 0-5mm. Its flow chart is as figure 1 shown. The prepared reclaimed sand has a particle size of 0-5mm, is relatively clean, has less debris content, and basically meets the technical requirements of the grinding process.

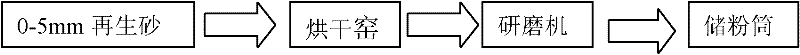

[0026] Then, send the ob...

Embodiment 2

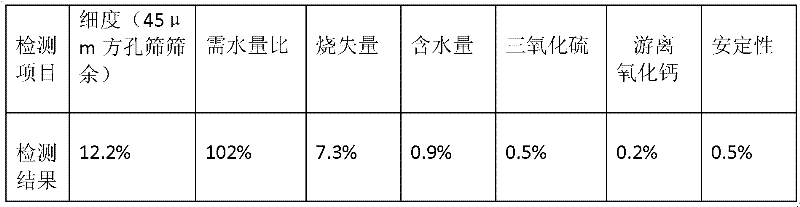

[0027] Embodiment 2, performance detection of regenerated powder

[0028] The regenerated powder in the present invention is a powder made by grinding the regenerated fine aggregate of construction waste as a main component of clay bricks and supplemented by concrete. Its inspection report is shown in the table below:

[0029]

[0030] In summary, compared with the prior art, the present invention has the following advantages and positive effects:

[0031] First of all, it improves the resource utilization value of construction waste. Experiments show that the regenerated construction waste powder produced by the method of the invention has high activity and can be used as an admixture for cement mixtures and various concrete products. The market value of recycled powder is one to two times higher than that of traditional recycled coarse aggregate and recycled fine aggregate, thus increasing the added value of resource utilization of construction waste.

[0032] Secondly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com